Drive and transducer interface choices, Auxiliary modules – Delta RMC101 User Manual

Page 29

RMC100 Startup

RMC100 Modules

29

deltamotion.com

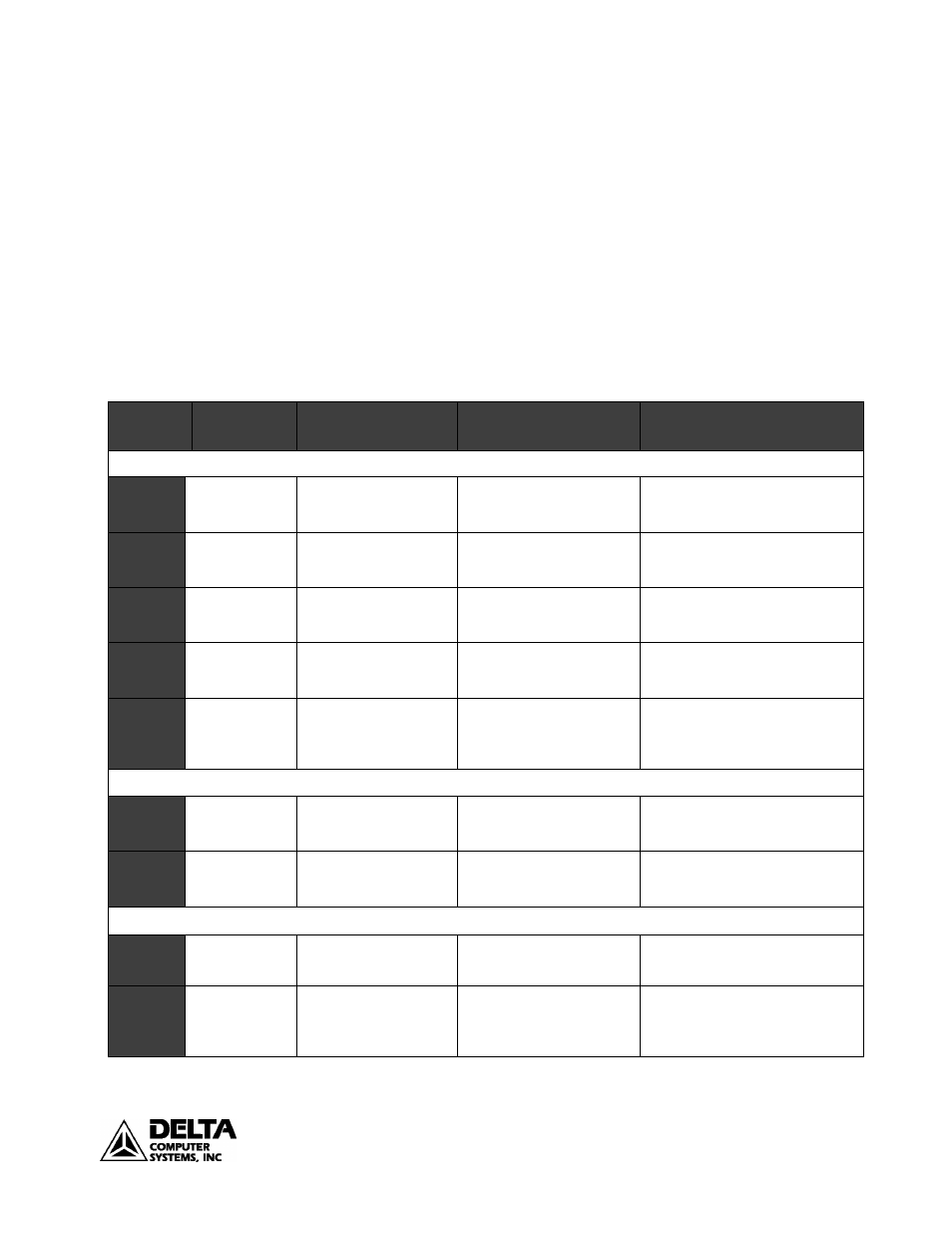

Drive and Transducer Interface Choices

Nine different I/O modules are available for the RMC100 Motion Controllers. Each

motion I/O module handles two axes, and RMC100 controllers can be configured

with one, two, three, or four I/O modules. I/O modules can be “mixed and

matched” for control of as many as eight axes with one motion controller. When

combined with the communication module choices, this I/O module flexibility

results in more than 500 configurations of the RMC100 motion controller available

off-the-shelf. Motion I/O modules are available with analog or stepper drive

outputs and interfaces for a wide variety of position feedback devices. Your choice

of Interface Modules will depend on the required performance and compatibility

match with your feedback devices and physical system.

RMC100

Interface

Module

Outputs

Inputs

Transducer

Compatibility

Performance

Motion Modules (Position Interface, Drive Outputs)

-Mn

2 Drive, ±10V*,

12-bit analog

2 MDT, PWM or

Start/Stop, RS-422

differential

Most MTS (Temposonics),

Balluff, and similar types

Absolute position, 120MHz count

rate for 0.001” res (one recirc)

-Sn

2 Drive, ±10V*,

12-bit analog

2 SSI, Binary or Gray

Code, 8-25 bits, RS-

422 differential

Absolute rotary encoders,

MDTs with compatible SSI

Absolute or incremental position,

High resolution, noise immunity

-Qn

2 Drive, ±10V*,

12-bit analog,

2 Enables

2 Quadrature (A, B, Z),

RS422 differential, and

6 discrete, 5-24Vdc

Quadrature encoders with

RS422 signals

Incremental position, 4,000,000

counts/sec, fast response to

index and home

-QSTn

2 Drive, Step &

Direction,

2 Enables

2 Quadrature (A, B, Z)

RS422 differential, and

6 discrete, 5-24 Vdc

Quadrature encoder

optional (with RS422

signals)

Drives up to 1 MHz, open or

closed loop, 4,000,000

counts/sec quadrature

-SSTn

2 Drive, Step &

Direction,

2 Enables

2 SSI, Binary or Gray

Code, 8-25 bits, RS-

422 differential

SSI transducer optional

(Absolute rotary encoders,

MDTs with compatible

SSI)

Drives up to 1 MHz, open or

closed loop, High resolution, high

noise immunity SSI, absolute

position

Motion or Auxiliary Modules (Analog Inputs for Position, Pressure, etc. Drive Outputs)

-Hn

2 Drive, ±10V*

12-bit analog,

+10V Exciter

4, 16-bit differential

analog

0-10V, ±10V, 0-5V, ±5V,

4-20mA

Absolute Position, Pressure or

Force, Position/Pressure

-Gn

2 Drive, ±10V*

12-bit analog,

+10V Exciter

2, 16-bit differential

analog

0-10V, ±10V

Absolute Position, Pressure or

Force, Position/Pressure

Auxiliary Modules

-An

None

4, 12-bit differential

analog

0-10V, ±10V, 0-5V, ±5V,

4-20mA

Analog reference, Pressure or

Force

-Dn

8 discrete SSR

(Solid State

Relay), 2.5kV

isolation

18 discrete, sinking,

Logic Polarity

configurable, 2.5kV

isolation

Outputs: ±30V, ±100mA,

1.5ms propagation delay

Inputs: 5-24V 6-10mA

max 2.0ms response

Comm DI/O, Fast response to /

triggering external events

*Use Delta’s VC2100 Voltage-to Current converter to convert ±10 Volts to current