Master control (plc or pc), Diagnostic tools, Plots – Delta RMC101 User Manual

Page 19

RMC100 Startup

Features of the RMC100

19

deltamotion.com

• Compare functions

• Math capabilities

• Trigger an event sequence from a digital input

• Conditional branching

Master Control (PLC or PC)

The RMC100 may be controlled from a PLC, a PC or other programmable

controller. The RMC100 provides a full range of communication options between

the RMC and the programmable controller. This enables the user to choose

between broadband control of the RMC for complex applications or limited control

for simpler applications.

The RMCWin on-line help contains highly detailed information for controlling the

RMC with each method of communication. The www.deltamotion.com web site

also contains many demonstration PLC programs.

This complete programming ability allows complex motions to easily be performed

by the RMC100.

Diagnostic Tools

The RMC100 contains diagnostic tools for monitoring and troubleshooting every

aspect of any motion it performs. A description of each follows.

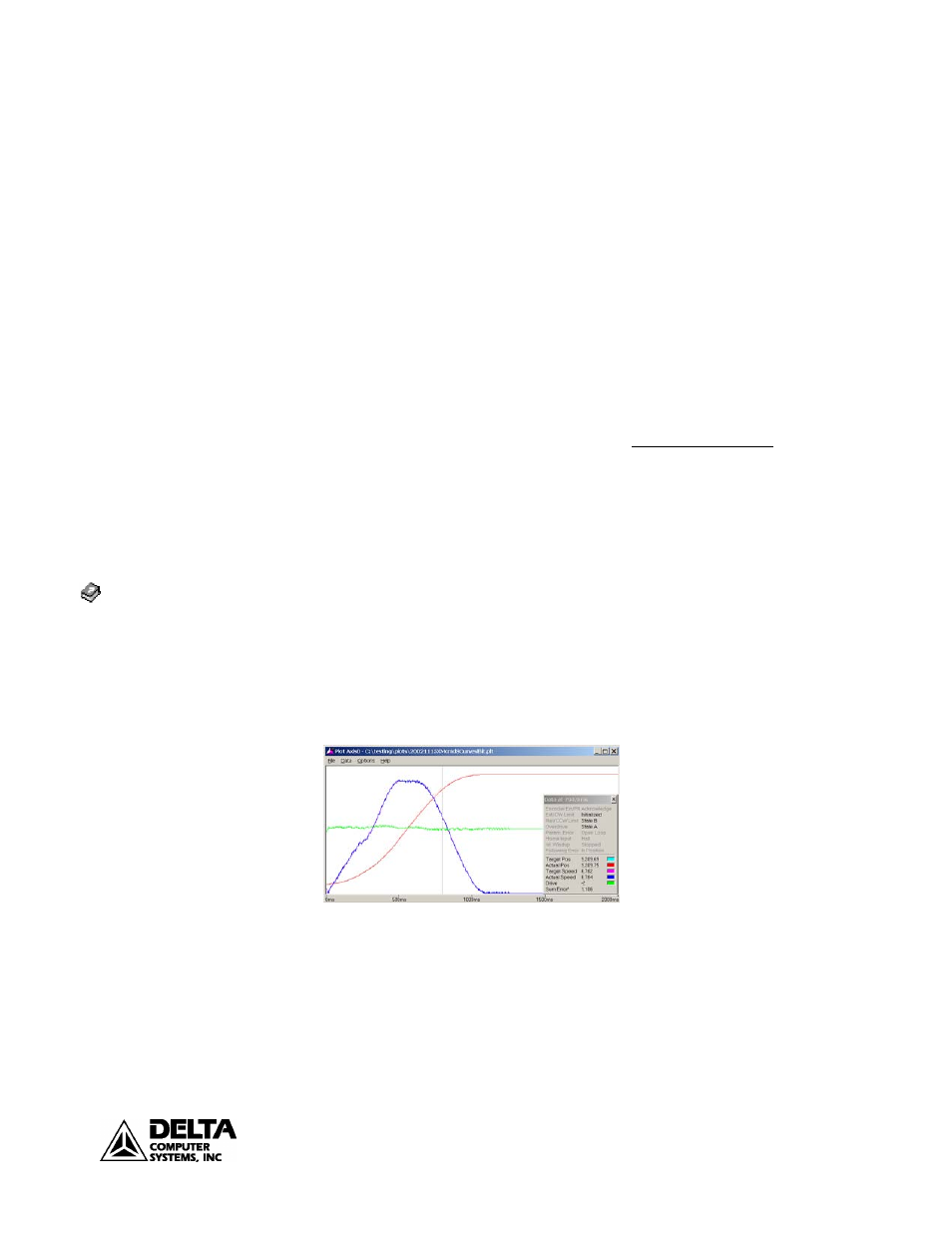

Plots

The plotting utility in the RMC100 is very powerful. Each move automatically

initiates a plot, in addition to the user being able to start a plot at any time. Each plot

contains the following useful information from an axis:

• Actual Position

• Target Position

• Drive

• Status Word

• Actual Speed

• Target Speed

• 2 user-selected pieces of data

The plotting utility is essential for tuning an axis. The user can view exactly what

happens at a resolution of down to 1 msec. The plotting utility also calculates the

Sum Error

2

, a quantitative measure of how close the actual trajectory follows the

target trajectory.

The plot data can also be viewed in numerical spreadsheet form.

Index/plots/using