S curves, Splines, Gearing – Delta RMC101 User Manual

Page 16

Features of the RMC100

RMC100 Startup Guide

16

deltamotion.com

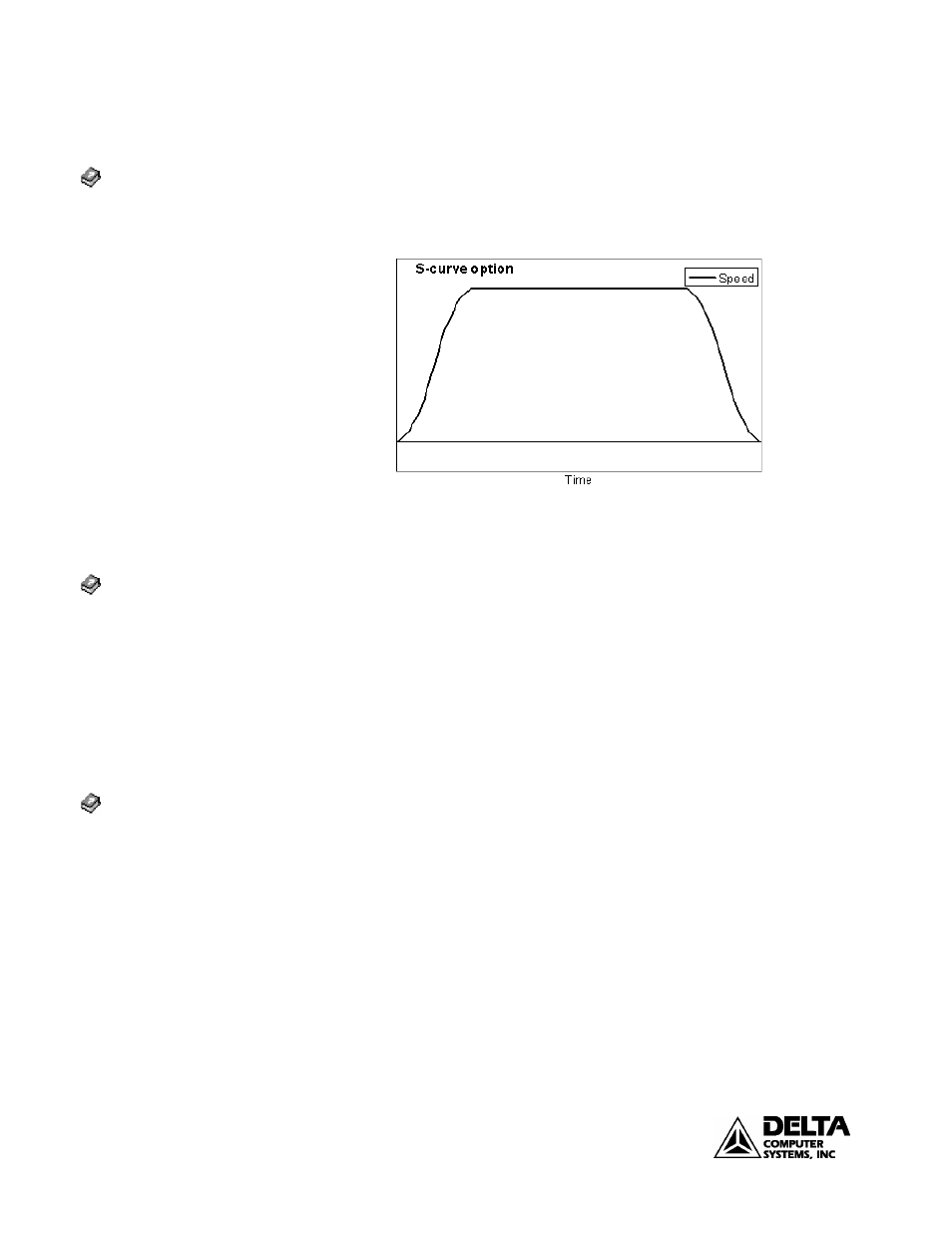

S Curves

For applications requiring smooth motion with more gradual starts and stops and

higher peak speeds, the RMC100 offers an "S-curve" option for the trapezoidal

motion profile. When this option is selected, the RMC100 calculates an s-shaped

target as shown below.

Splines

Some applications require that the motion controller move between a number of

given positions. The splines feature of the RMC100 greatly simplifies such

applications. The user only needs to enter the desired points at certain intervals and

the RMC100 automatically calculates the intermediate positions while maintaining

smooth motion free from jerks or discontinuities.

The splines positions can be placed as a function of time, position units from an

axis, or counter ticks from a digital I/O input. This makes the splines feature a

powerful tool for applications such as curve sawing, animatronics, cyclical testing

and electronic camming among others.

Gearing

Gearing is used when one axis (the geared axis) must move incrementally and

proportionately to another axis (the gear master). The RMC100 easily performs this

so-called electronic gearing (as opposed to mechanical gearing) and allows the user

many options.

The RMC100 allows any axis to be geared to another axis or to a position input

encoder. Setup is simple since the master axis does not need to do anything to be

the master. Multiple axes may be geared to the same master.

The user specifies the gear ratio, which can be changed at any time. When issuing a

gearing command, the geared axis must change its speed to the speed dictated by

the user-specified gear ratio. This is called clutching. The RMC100 has 3 methods

of specifying clutching, which makes the task of synchronizing the axis to the rest

of the system simple.

Index/Splines/Spline Overview

Index/gearing/Gearing Axes

Index/s curves/S curves

scroll to bit 7