5f,h open-drive compressors – Carrier 5F User Manual

Page 38

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

5F,H

Open-Drive Compressors

TROUBLESHOOTING (cont)

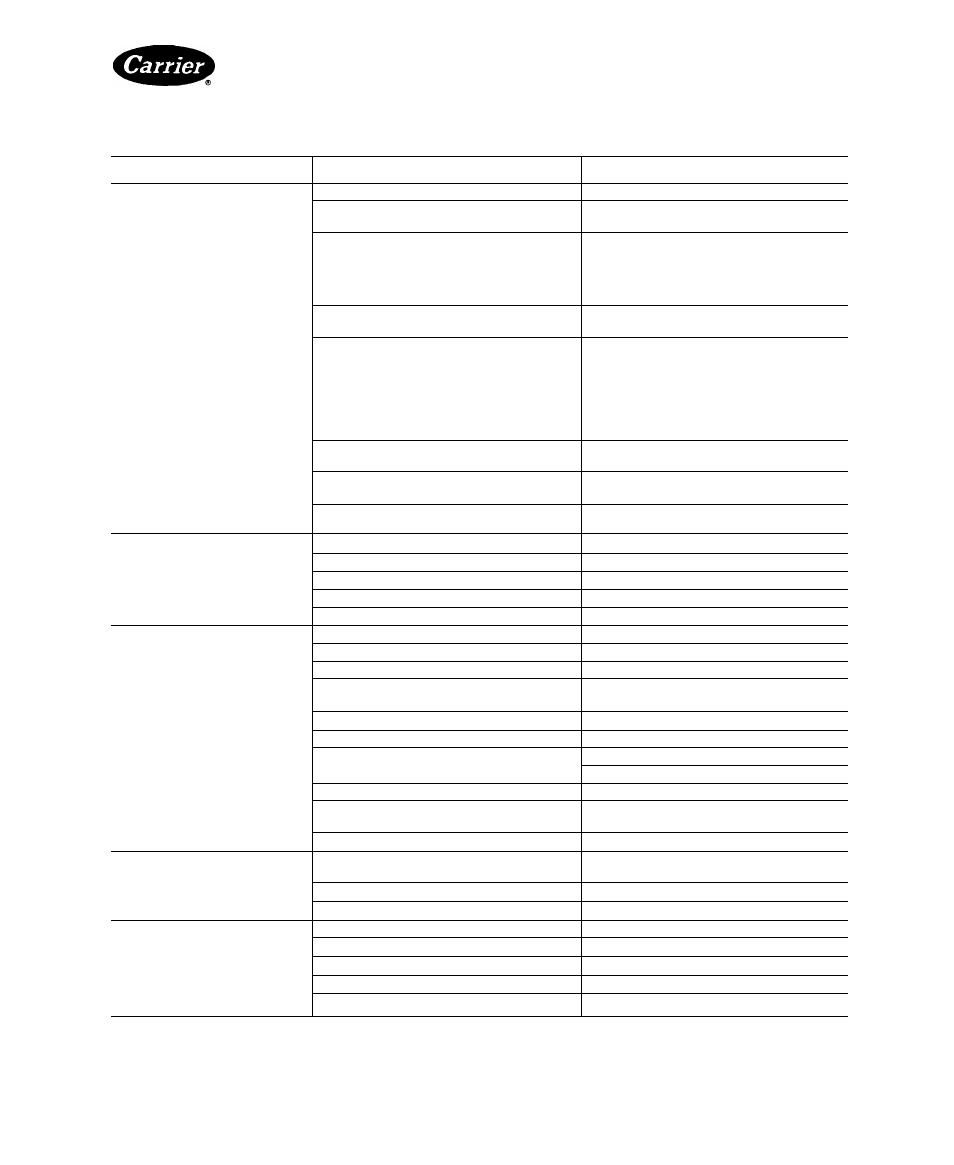

TROUBLE/SYMPTOM

PROBABLE CAUSE

REMEDY

System noises, (cont)

Unit foundation improperly isolated.

Isolate foundation.

Improper support or isolation of piping.

Use correct piping techniques and support

piping with suitable hangers.

Slugging from refrigerant feedback.

Check expansion valve setting. Check

thermal bulb looseness and correct

location. See Carrier System Design

Manual, Part 3 for standard piping

techniques.

Hydraulic knock from excessive oil in

circulation.

Remove excess oil. Check expansion

valve for floodback.

Defective valve lifter mechanism (noise

level varies with unloading).

Replace sticking filter pins. Check un

loader fork for alignment. Check power

element for sticking piston. Check for oil

leakage at tube connection to power

element. Check amount of valve pin lift

above valve seat (0.33 in. for 5F; 0.125 in.

for 5H).

Piping vibration.

Support pipes as required. Check pipe

connections.

No muffler in discharge line or improperly

located.

Install muffler. Move muffler closer to

compressor.

Hissing (insufficient flow through expan

sion valves, orclogged liquid line strainer).

Add refrigerant. Clean strainer

Compressor will not unload.

Capacity control valve not operating.

Repair.

Unloader element sticking.

Repair.

Hydraulic relay sticking.

Replace control cover assembly.

Plugged pressure line to power element.

Clean line.

External adjusting stem damaged.

Replace.

Compressor will not load.

Low oil pressure (below 35 psi).

Check oil charge, switch settings.

Capacity control valve stuck open.

Repair or replace.

Unloader element sticking.

Repair.

Plugged or broken pressure line to power

element.

Clean or repair.

External adjusting stem damaged.

Replace.

Control oil strainer blocked.

Clean or replace.

Control valve bellows leaking.

Remove thread protector and leak test.

Replace valve body if bellows leaks.

Pipe plug in pneumatic connection.

Remove pipe plug.

Foaming in crankcase ^rom refrigerant

flooding.

Check expansion valve and piping.

Hydraulic relay sticking.

Replace control cover assembly.

Rapid unloader cycling.

Excessive fluctuation in suction pressure

from oversized expansion valve.

Resize expansion valve.

Partially plugged control oil strainer.

Clean or replace strainer.

Low oil pressure.

See Trouble/Symptom — low oil pressure.

Low oil pressure.

Low oil charge.

Add oil.

Faulty oil gage.

Check and replace.

Defective oil pressure regulator.

Repair or replace.

Clogged oil suction strainer.

Clean strainer.

Broken oil pump tang.

Replace pump assembly.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book! 2

PC111

Catalog No 530-526

PrintedinUSA

Form 5F,H-11SI

Pg 38

2-86

Replaces: 5F,H-9SI

Tab 2a

For replacement Hems use Carrier Specified Parts.