5f,h open-drive compressors – Carrier 5F User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

5F,H

Open-Drive Compressors

INSTALL CRANKCASE HEATER — Wire heater to

relay or set of normally closed auxiliary contacts on

compressor starter to de-energize it when compressor

is operating.

Remove rubber plug from crankcase heater casing

(Fig. 1-8), and insert heater element entirely into casing.

Element should fit snugly, not loosely. Wire to comply

with applicable electrical codes.

When crankcase heater is installed, system can be

operated on single pumpout cycle, unless used with a DX

cooler.

Table 2 lists crankcase heater packages. Table 3 shows

corresponding relays. Use of 2 heaters on a 5H80 or

5H120 compressor requires only one relay.

Control circuit voltage determines relay coil voltage.

This voltage must be specified when ordering relays.

See Accessory Compressor Crankcase Heater Instal

lation Instructions for additional information.

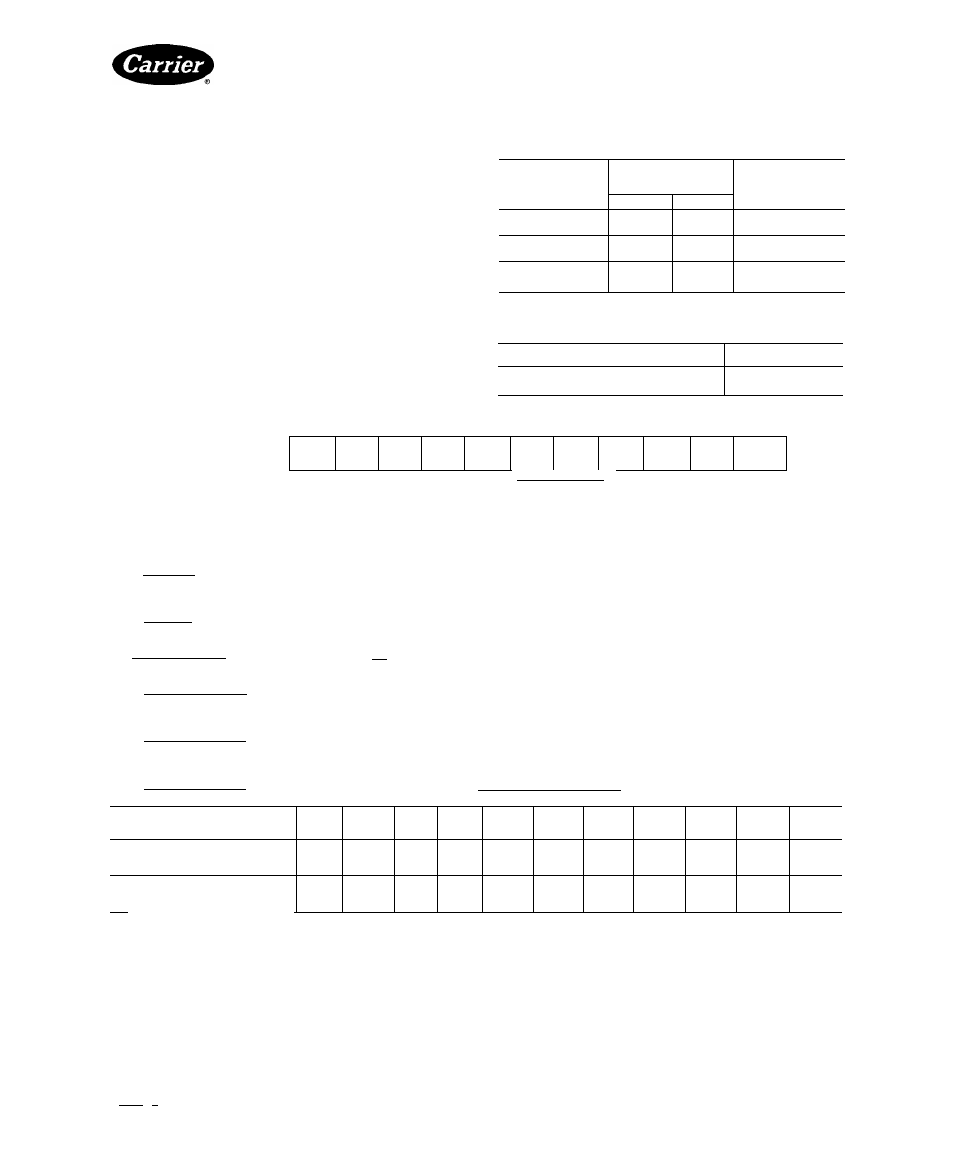

Table 2 — 5F,H Compressor Crankcase

Heater Package

COMPRESSOR

ELECTRICAL

CHARACTERISTICS

PACKAGE NO.

Volts

Watts

5F20,30,40,60

115

230

100

100

-5-F-20—381

-5-F-20—391

5H40,46,60,66

115

230

200

200

-5-H-40—381

-5-H-40—391

5H80,86,120,126

115

230

200

200

-5-J-40—281

-5-J-40—291

Table 3 — Crankcase Heater Relay (60 Hz)

CONTROL CIRCUIT VOLTAGE

PART NO.

115

HN61AJ-101

208/230

HN61AJ-108

Table 4 — Physical Data

COMPRESSOR

UNIT

AND

CONDENSING UNIT

5F20

5F30

5F40

5F60

5H40

5H46

5H60

5H66

5H80

5H86

5H120

REFRIGERANT

R-12, R-22, R-502

COMPRESSOR DATA

Maximum Rpm

Minimum Rpm

Minimum Rpm Capacity

Control

600

700

800

1750

400 (required for proper lubrication)

900

800

800

900

900

1100

1100

900

900

Number of Cylinders

Bore (in.)

Stroke (In.)__________

2

2'/2

2

3

2'/2

2

4

2'/2

2

6

2'/2

2

4

3V

a

2%

4

3’/4

3%

6

3%

2%

6

3'/4

3y,6

8

3'/4

2%

8

3'/4

3V,6

12

3'/4

2%

12

3'/4

3V,6

Compressor

Connections

(in. O.D.)

Suction

Discharge

VA

Ve

IVs

1%

V/e

1%

2Ve

VA

2%

2'A

2%

2'A

3'A

3'A

3'A

3'A

3'A

3'A

3'A

3'A

4'/e

4'A

4'A

4'A

Oil Charge* (pt)

(See Notes)

Normal Oil Pressure*

Oil Flow Rate (gpm)___________

55

12

13

18

18

21

21

41

45-55 psig above suction pressure —

1 5_____________I_____________________ 3_0___________

41

61

61

4.5

Oil Safety Switch

Cut-in (psig)

(See Notes

Cutout (psig)

3 and 4)

15 - 19.5

11 - 15

High-Pressure Switchf

Cutout Range

Differential (psi)

Factory Setting (psig)

150-395 (adjustable) nominal

60-150 (adjustable)

Cutout, 300 ± 15, Cut-in, 210 ± 10

Low-Pressure Switchf

Cutout Range

Differential (psi)

Factory Setting (psig)

20 in Hg vac to 60 psig (adjustable)

60-90 (adjustable)

Cutout, 50 ± 4; Cut-in, 120 ± 6

Low Side Maximum Pressure

245 psig

CONDENSER DATA

5F20f

5F30f

5F40

5F60

09RH-

027

09RH-

043

09RH-

054

09RH-

070

09RH-

084

09RH-

097

09RH-

127

Maximum Refrig-

R-12

40 4

50 7

79.4

89 6

154

212

263

238

282

358

475

erant Storage

R-22

37 2

46.4

72 8

82 0

139

193

239

216

257

327

432

Capacity** (lb)

R-502

38.2

47.9

75.0

84.6

145

199

248

223

265

337

447

Minimum Refrig-

R-12

20

30

140

160

37.0

41 0

51 0

51 0

78

100

126

erant Operating

R-22

1 8

27

127

14.5

33.0

37 0

46.0

46 0

71

91

114

Charge (ib)

R-502

1.9

2.9

13.1

15.0

34.4

38.2

47.3

47.3

73

94

118

Maximum Operating Pressure

Refrigerant Side

Water Side

150 psig

385 psig

250 psig

‘Nominal oil pressures shown in Physical Data table are above suction

pressure, i e , pressure differential between suction pressure and dis

charge pressure of oil pump

tSee Table 5 for typical pressure switch settings

fShell-and-coil condensers All other 5F,H condensers are shell-and-

tube

‘‘Condenser storage capacity 80% filled with liquid refrigerant at 90 F

NOTES:

1 Oil flow rate is the nominal oil pump capacity

2 The following oil (or equivalents) are specified for use in 5F,H

compressors

5F20 and 30: Witco Chemical Co — Suniso 4GS

5F40-5H126: Witco Chemical Co. — Suniso 3GS

Texaco, Inc — WF32

Shrieve Chemical Co — Zerol 150 (synthetic)

3 Differential switch (oil safety switch) has time delay of 30 to 60 seconds

4 Oil safety switch has manual reset

Book 12

PC 111

Catalog No 530-526

Printed inUS A

Form5F,H-11SI

Pg12

2-86

Replaces: 5F,H-9SI

Tab 12a

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

For replacement items use Carrier Specified Parts.