A caution, Adjust capacity control (if required) — see, Adjust capacity control (if required) – Carrier 5F User Manual

Page 14: 5f,h open-drive compressors, Caution

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

5F,H

Open-Drive Compressors

Start Compressor — Close main power switch

supplying current to the compressor motor.

Immediately recheck oil level and check oil pressure.

Pressure should exceed suction pressure by 45-55 psi.

If correct pressure is not reached in 10-12 seconds, stop

compressor immediately and check oil pump.

A

CAUTION

If any safety device shuts down the compressor, do

not reset the control more than once before deter

mining cause of shutdown.

Check Control Operation — Refer to Carrier

Standard Service Techniques Manual, Chapter 2, for

complete instructions on checking electrical components.

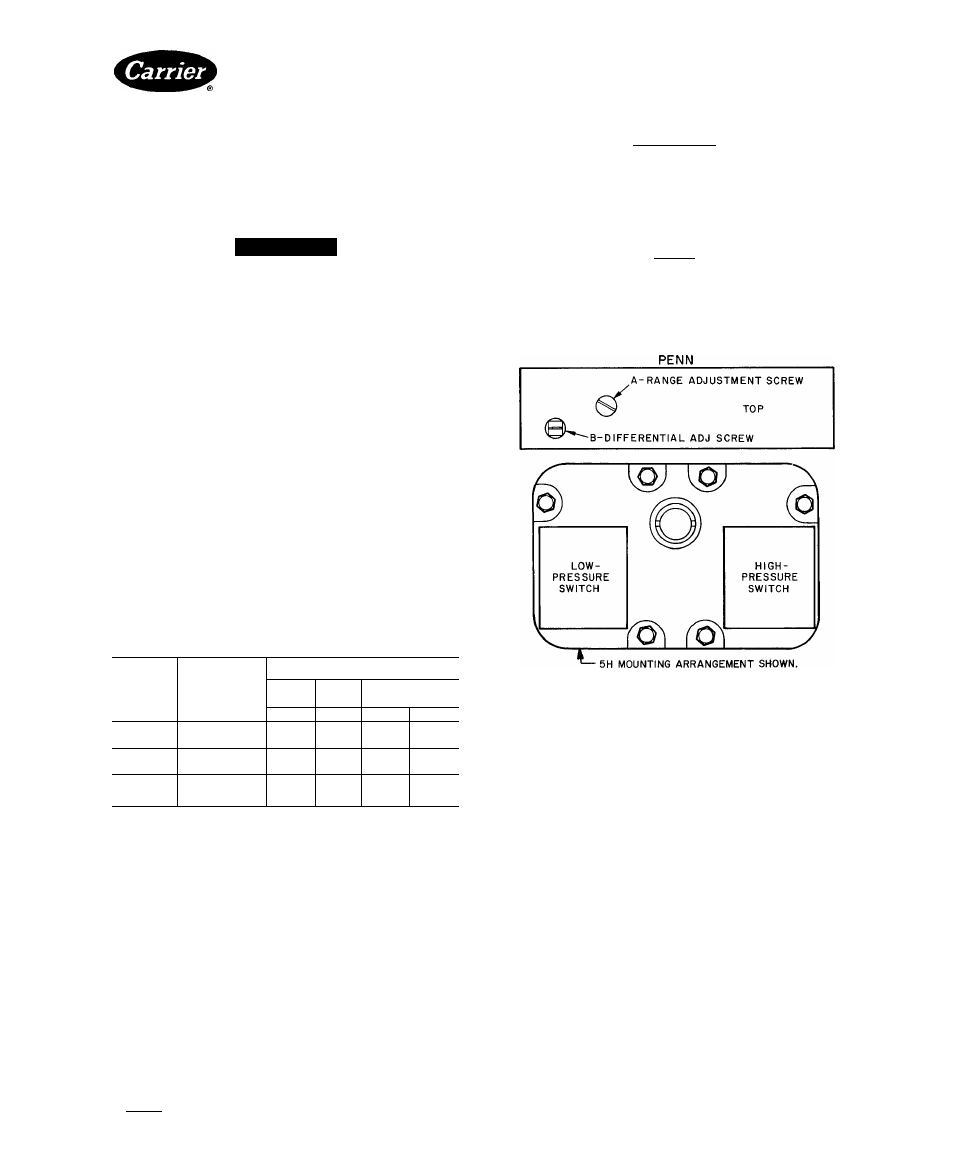

HIGH- AND LOW-PRESSURE SWITCHES — A115F

and 5H units except 5F20 and 30 have factory-installed,

automatic reset, high- and low-pressure switches. (These

switches are available as accessories for 5F20 and 30

units.) Figure 13 illustrates adjustment procedures for

both switches.

Check High-Pressure Switch — Throttle the con

denser water on water-cooled unit or block the airflow

on air-cooled unit, allowing head pressure to rise grad

ually. Compressor should shut off within 15 psi of cutout

value listed in Table 4. Now reverse procedure; com

pressor should start within 10 psi of cut-in value given.

Check Low-Pressure Switch — Slowly close the

suction service valve; suction pressure will decrease.

Compressor should shut off within 4 psi of cutout value

listed in Table 5. Reverse procedure; compressor should

start within 6 psi of cut-in value given.

Table 5 — Typical Pressure Switch Settings

REFRIG

ERANT

CONDENSER

PRESSURESTAT

Hi!

(ps

g)

Low

(psig)

Cutout

Cut-in

Cutout

Cut-in

Water-Cooled

175

95

16

76

Air-Cooled

225

145

16

76

Water-Cooled

280

200

36

96

Air-Cooled

325

245

36

96

Water-Cooled

280

200

45

105

Air-Cooled

325

245

45

105

OIL PRESSURE SAFETY SWITCH — To check, move

contact arm at left side of switch forward (Fig. 14).

Compressor should stop in approximately 45 seconds.

If compressor continues to run, check the wiring to

safety switch. If wiring is correct, switch is faulty and

should be replaced.

After completing test, wait 3 minutes; then press

restart button on front of safety switch and restart

compressor.

Check oil level in compressor sight glass after 15-20

minutes of operation. If the oil level is low, add oil by the

methods described in Carrier Standard Service Tech

niques Manual, Chapter 1, Section 1-11.

If an accessory oil cooler is provided, adjust the

water flow as required to maintain a lOOF to 120F

crankcase return oil temperature.

ROBERTSHAW

A-RANGE ADJUSTMENT SCREW

TOP

B-DIFFERENTIAL ADJ SCREW

0'^B-

RANCO

A-RANGE ADJUSTMENT SCREW

TOP

DIFFERENTIAL ADJ SCREW

Screw A raises or lowers both cutout and cut-in points by a like

amount.

Range and Differential scales are on the front of the switch.

High Pressure Set

cutout

point first, with screw A; then set

cut-in

point with screw B

Low Pressure: Set

cut-in

point first, with screw A, then set

cutout

point with screw B

LOCATION AND ADJUSTMENTS

Fig. 13 — High- and Low-Pressure Switches

For additional information, see Oil Safety Switeh

Accessory Package Installation Instructions.

Adjust Capacity Control (if required) — See

Fig. 17 for unloading sequence.

5F20 AND 5F30 COMPRESSORS ^ Referto Capacity

Control Valve Installation Instructions for additional

information.

5F40 THROUGH 5H126 COMPRESSORS — Deter

mine the refrigerant usage:

If the system is to use R-I2, replace the 11-lb range

adjustment spring (Fig. 15) with the 7-lb spring .supplied

with compressor. A change in 1982 reversed which range

adjusting spring a customer received. The R-22/R-502

spring is now standard with the compressor. See instruc

tion tag for spring replacement procedure.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without Incurring obligations.

Book! 2

PC111

Catalog No 530-526

PrIntedInUSA

Form5F,H-11SI

Pg14

2-86

Replaces: 5F,H-9SI

For replacement items use Carrier Specified Parts.

Tab 2a