5f,h open-drive compressors – Carrier 5F User Manual

Page 37

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

5F,H

Open-Drive Compressors

TROUBLESHOOTING

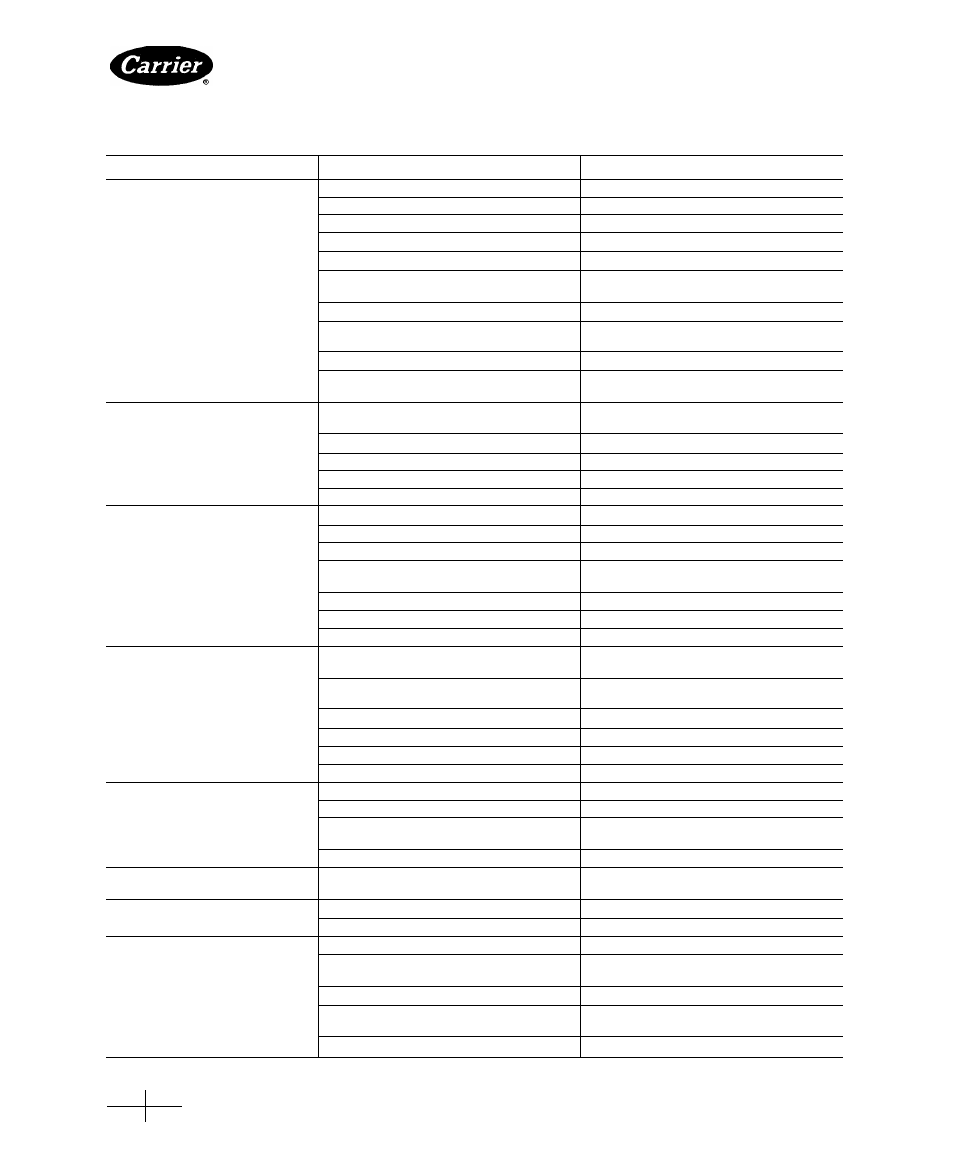

TROUBLE/SYMPTOM

PROBABLE CAUSE

REMEDY

Compressor will not start.

Power off.

Check main switch, fuse and wiring.

Thermostat set too high.

Reset thermostat.

Thermal overload switch open.

Reset switch.

Oil safety switch open.

Reset switch.

Dirty contacts.

Clean all control contacts.

Loose electrical connections or faulty

wiring.

Tighten connections; check wiring and

rewire.

Compressor motor burned out.

Check and replace If defective.

Liquid line solenoid valve closed.

Check for burned-out holding coil.

Replace if defective.

Evaporator fan off.

Check fuses, overload. Restart.

Evaporative condenser or cooling tower

fan or pump not operating.

Check fuses, overloads and controls.

Restart.

Compressor cycles intermittently.

Low-pressure switch erratic in operation. Check for clogged tubing to switch.

Check switch setting.

Low refrigerant charge.

Add refrigerant.

Capacity control setting incorrect.

Reset.

Thermostat differential too narrow.

Reset.

Suction valve closed or throttled.

Open up valve.

Compressor cycles on high

pressurestat.

Tubing to pressurestat restricted.

Check and clean tubing.

Faulty pressurestat.

Repair or replace.

Refrigerant overcharge.

Remove excess refrigerant.

Insufficient condenser water flow or

clogged condenser.

Adjust water regulating valve to con

denser. Clean condenser.

Discharge service valve not fully open.

Open valve.

Air in system.

Purge air.

Condenser water pump off.

Check pump and start.

High discharge pressure.

Condenser inlet water temperature too

high.

Increase water quantity by adjusting water

regulating valve. Use colder water.

Insufficient water flow through condenser. Readjust water regulating valve. Increase

size of water supply main to condenser.

Plugged or scaled condenser tubes.

Clean tubes.

Discharge service valve partially closed.

Open valve.

Refrigerant overcharge.

Remove excess refrigerant.

Air in system.

Purge air.

Low discharge pressure.

Excessive water flow through condenser. Adjust water regulating valve.

Suction service valve partially closed.

Open valve.

Leaky compressor suction valves.

Examine valve discs and valve seats.

Replace if worn.

Worn piston rings.

Replace.

Flooding

Defective or improperly set expansion

valve.

Reset to 5 F -10 F superheat. Valve opera

tion must be stable (no hunting).

Low suction pressure.

Low refrigerant charge.

Add refrigerant.

Excessive superheat.

Reset expansion valves.

System noises.

Loose or misaligned coupling.

Check alignment and tightness.

Insufficient clearance between piston and

valve plate.

Replace defective parts.

Motor or compressor bearing worn.

Replace bearings.

Loose or misaligned belts.

Check alignment and tension. (Belt slack

should be at top.)

Loose holddown bolts.

Tighten bolts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book

2

PC111

Catalog No 530-526 PrintedinUSA Form5F,H-11SI

Pg 37

2-86

Replaces: 5F,H-9SI

Tab

2a

For replacement items use Carrier Specified Parts.