Scheduled maintenance, 5f,h open-drive compressors – Carrier 5F User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING «COOLING

5F,H

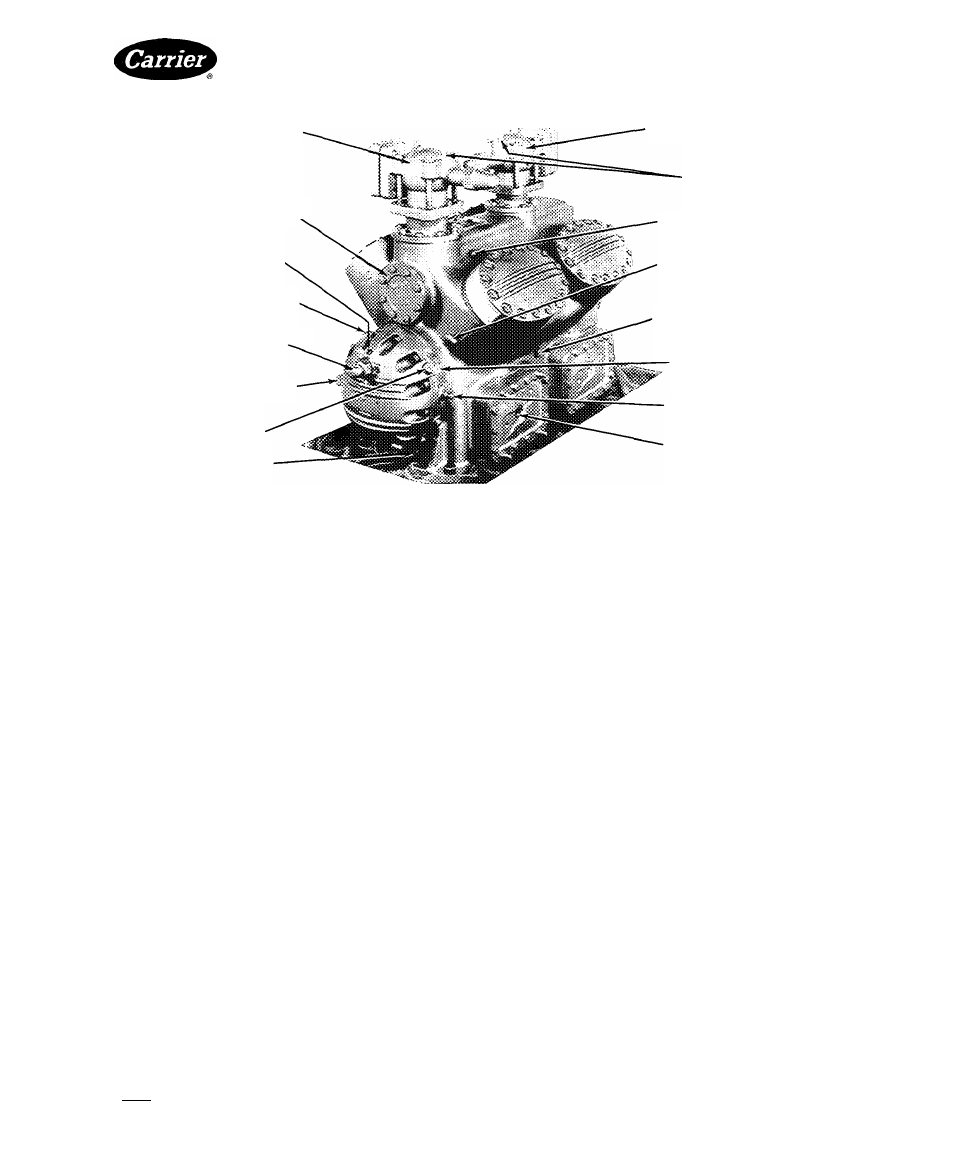

Open-Drive Compressors

SUCTION

SHUTOFF

VALVE

3-1/8“ ODF

SUCTION MANIFOLD COVER

(REMOVE FOR ACCESS TO

SUCTION STRAINER)

PNEUMATIC

CONTROL

CONNECTION 1/4“ IPS

OPENING

TO

CRANKCASE

1/4" IPS

CAPACITY

CONTROL

VALVE

ADJUSTING STEM

CONTROL

OIL

STRAINER

PLUG 5/8“-18

OIL

FILLER

PLUG

CRANKCASE DRAIN

DISCHARGE

SHUTOFF

VALVE

3-1/8“ ODF

GAGE

CONNECTIONS

1/4“ IPS

HIGH-PRESSURE

CONTROL

CONNECTION 1/4" IPS

LOW-PRESSURE

CONTROL

CONNECTION 1/4“ IPS

CENTER MAIN BEARING

RETAINING SCREW ACCESS

OIL PUMP

ROTATION ARROW (TAG)

CONTROL OIL PRESSURE

OIL LEVEL SIGHT GLASS

Fig. 18 — 5H80, 86 8- Cylinder Compressor

m

SCHEDULED MAINTENANCE

5F,H compressor and condensing units provide long

life and dependable service when properly operated and

regularly maintained. Establish a maintenance schedule

based on factors such as operating hours, load eonditions

and water quality. Maintenance schedules listed in this

section are offered as guides. Modify them as needed to

satisfy individual machine requirements.

Check Lubrication System — Always check com

pressor oil level before starting unit. If oil is required,

record date and amount added. Refer to Fig. 1-8 for loca

tion of oil filter plug. Table 4 shows specified types and

quantities of oil.

Use of accessory oil separator requires additional oil.

Oil level and separator float valve movement during

initial compressor operation should agree with instruc

tions furnished with the oil separator.

OIL FILTER MAINTENANCE — A bleed-type, high-

pressure, disposable filter is available as an accessory

for 5H40 through 5H86 eompressors (Fig. 19). Replace

oil filter after the first 50 hours of operation, or whenever

the oil is changed or becomes dirty.

Check yearly for clogged filter, indicated by a greater

than normal difference between oil pressure ahead of

fdter and after filter. When this difference exceeds 5 psig,

change filter as follows;

1. Close oil-line shutoff valves on each side of filter

(Fig. 19).

2. Disconnect oil lines at filter connections.

3. Loosen filter bracket; remove and replace filter body.

Refer to Accessory Oil Filter Instructions for

additional information.

The full-flow oil filter on 5H120 and 5H126 com

pressors contains a replaceable cartridge. Replaee the

filter cartridge after the first 100 hours of compressor

operation. After the initial filter change, check yearly for

filter clogging. If the pressure difference across the filter

exceeds 5 psig, pump down the compressor and then

remove the cartridge. Figure 20 illustrates complete

filter assembly.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|2

PC111 Catalog No 530-526 PrintedinUSA

Form5F,H-11SI Pg17 588

2-86 Replaces: 5F.H-9SI

For replacement items use Carrier Specified Parts

Tab 2a