Connecting rods and pistons, 5f,h open-drive compressors – Carrier 5F User Manual

Page 28

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

5F,H

Open-Drive Compressors

To reassemble:

1. Rotate crankshaft to position piston at top center.

2. Lubricate piston rings and beveled surface at lower

edge of cylinder sleeve.

3. Stagger ring gaps around piston.

4. With turning motion, work sleeve over piston and

rings. Compress and align each ring with beveled edge

of sleeve.

5. Seat sleeve in suetion manifold partition and cylinder

deck recess.

6. Rotate sleeve so that any 2 valve lifter-pin holes lie

equal distances from longitudinal axis of compressor

(Fig. 35). In this position, lifter pins line up with

suction valve springs.

install cap so chamfered sides are against radius of

crankpin. (Small knobs on rod and caps must be on same

Connecting Rods and Pistons

REMOVAL — Remove cylinder head, valve plate and

handhole cover or bottom plate to gain access to rods

and pistons.

Remove connecting rod caps (Fig. 22). Label caps and

rods so they may be reinstalled in same places on crank

shaft. Remove cylinder sleeve, connecting rod and piston

assembly as a unit by pushing assembly up through

cylinder deck. Do not allow piston to come up through

top of sleeve during removal process. Remove retaining

rings and piston pins to disassemble connecting rods from

pistons. Remove rings.

Keep each individual connecting rod and piston

assembly together to aid reassembly. Check all parts

and crankpin journals for wear (Table 11).

INSPECTION

AND

REPLACEMENT

Attach

con

necting rods to pistons with piston pins and lock in place

with retaining rings. Piston pins are selectively fitted for

a push fit; reassemble in the piston from which they

were removed. Place piston pin retaining rings, with gap

on side, on piston (Fig. 34). They should be tight

enough to inhibit rotation under finger pressure.

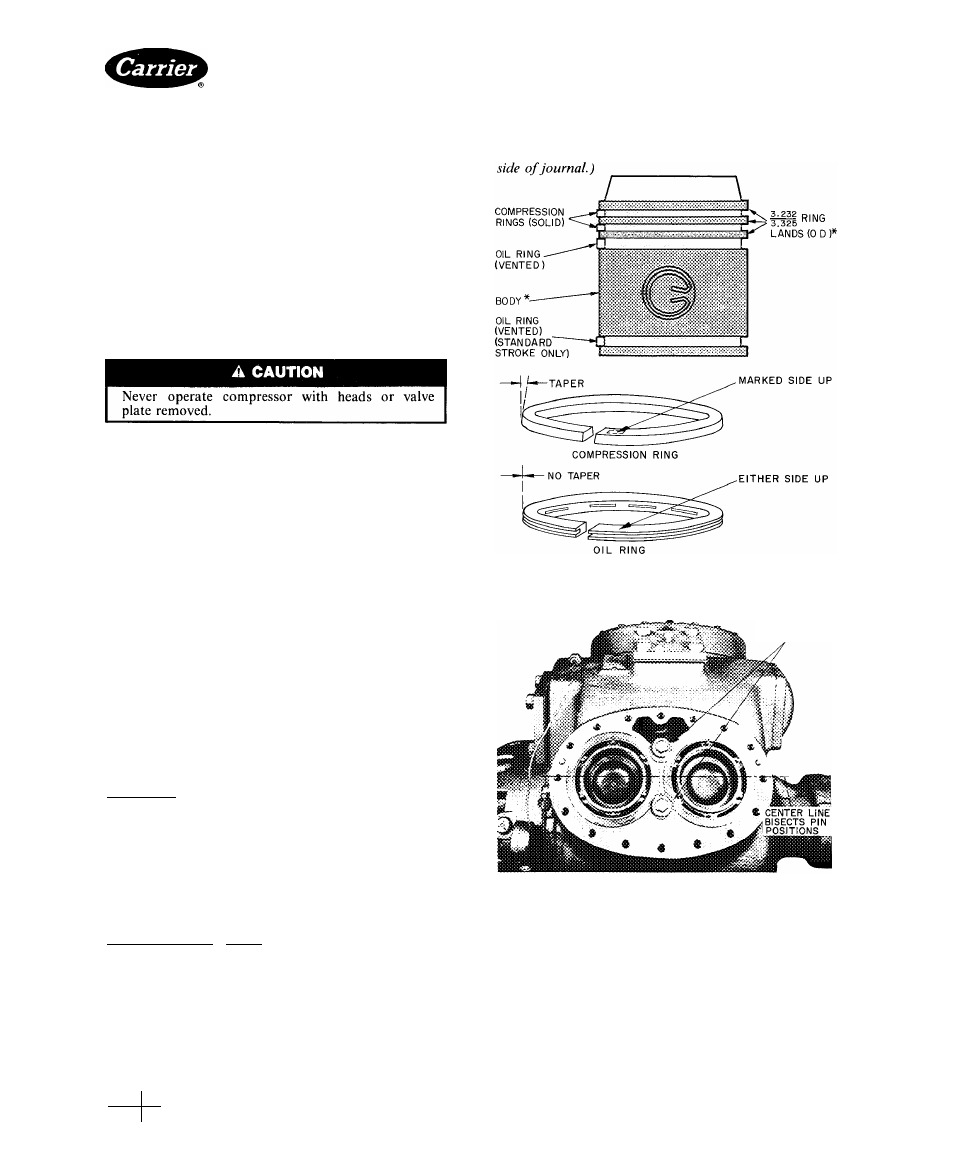

Check Rings

1. Check ring gap by inserting each ring separately in

cylinder approximately 3/8in. from top. Ring gap

should be between .007 and .017 inches.

2. Install compression rings on piston with side marked-

top toward piston head. Install oil rings either side up.

3. Stagger ring gaps around piston.

4.

Measure side clearance between ring and piston

(approximately .001 inch). Check rings for free action.

Check Rod Bearing Inserts (Fig. 22) — If bearing inserts

are damaged and crankshaft is not worn, it is only

necessary to replace inserts. Do not file bearing caps.

Place the inserts in connecting rod and connecting rod

caps so knobs on inserts fit into notches on rod cap.

Lubricate insert bearing and crankpin freely before

installing caps.

Install cylinder sleeve, eonnecting rod and piston

assembly at the same time. Turn connecting rod, and

'See Table 11 for piston diameters.

Fig. 34 — Aluminum Long-Stroke Piston Details

CAP

SCREWS

AND WASHERS

Fig. 35 — Position of Cylinder Sleeves

Capacity Control Operation — All 5F,H series

compressors, except 5F20 and 30 units, include hydraulic

capacity control unloader systems as standard equip

ment. (Field-installed accessory unloader packages are

available for the 5F20 and 30.) The unloader system

activates

and

deactivates

the

compressor’s

cylinder

banks, by permitting suction valves to seat or preventing

them from doing so, in response to changing load de

mands. Capacity control unloaders can reduce a unit’s

actual operating capacity by steps down to as little as 25%

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC111

Catalog No 530-526

PrintedinUSA

Form5F.H-11SI

Pg 28

2-86

Replaces: 5F.H-9SI

For replacement items use Carrier Specified Parts

Book

2

Tab

2a