Service instructions, Service notes, Lubrication system – Carrier 5F User Manual

Page 19: 5f,h open-drive compressors

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

5F,H

Open-Drive Compressors

#

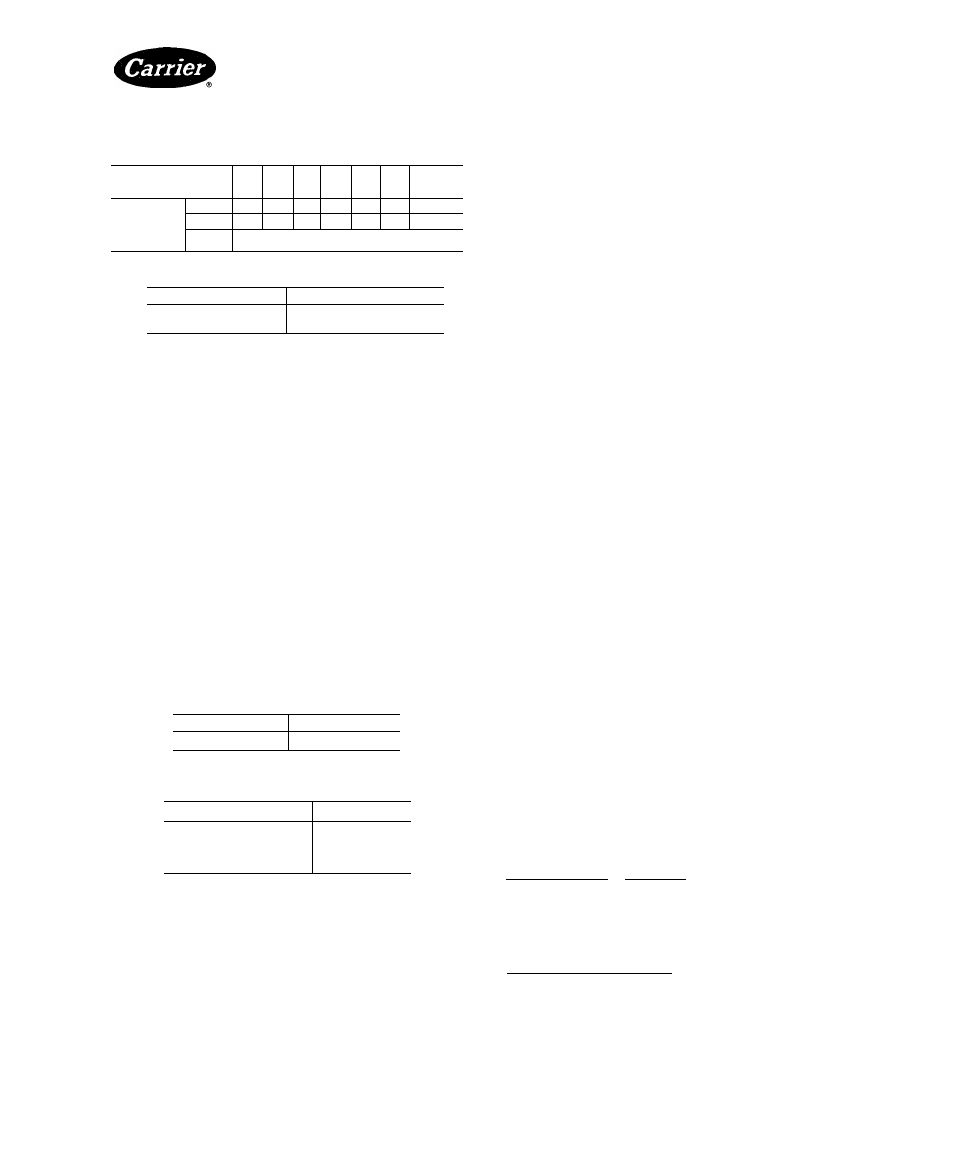

Table 7 — Actual Suction Gas

Temperature Limits (F), R-12, R-22, R-502

SAT. SUCT

TEMP (F)

-60

-50

-40

-30

-20

-10

Oto 50

ACTUAL

SUCTION

GAS

TEMP(F)

R-12

—

—

35

45

55

65

65

R-502

25

35

45

55

65

75

75

R-22

See Note 1

NOTES:

1 For continuous operation with R-22

SAT. SUCT TEMP (F)

MAX. SUPERHEAT (F)

-40 to 40

25

40 to 50

15

2 Do not operate unloaders at saturated suction temperatures

at or below 0°F without prior approval from Carrier/Carlyle

Engineering

3. The compressor operates fully unloaded for prolonged

periods. Under these conditions, suction gas levels

may not suffice to remove the heat of compression

and friction. This condition can occur in any applica

tion, but is most likely in low-temperature systems or

variable-volume applications that use hot-gas bypass

to maintain specified conditions under low evaporator

load. Refer to 5F,H Application Data for additional

information.

Adjust water flow through oil cooler to maintain

crankcase return oil temperature at 100 to 120 F. Crank

case temperature must remain below 140 F; shaft seal

temperature at the seal housing should not exceed 170 F.

Tables 8 and 9 list maximum working pressures for

oil and water and estimated water flow rates for various

oil

cooler/compressor

combinations.

For

additional

information,

see

Accessory

Oil

Cooler

Installation

Instructions.

Table 8 — Oil Cooler Maximum Working Pressure

OIL

150 psig

WATER

150 psig

Table 9 — Oil Cooler Estimated Water Flow Rates

COMPRESSOR

GPM*

5F

’/4-1

5H40-66

1-2

5H80,86

1

'/2 -

3

5H120.126

2-4

*Flow rate based on 80 F entering water.

Check Water-Cooled Heads — To prevent oil

breakdown and sludge formation, the discharge gas

temperature must remain below 275 F. Water-cooled

cylinder heads are available as an accessory for this

purpose. See Accessory Water-Cooled Head Package

Installation Instructions for additional information.

SERVICE INSTRUCTIONS

Service and repair of Carrier reciprocating com

pressors and other refrigeration components should be

performed only by fully trained and qualified personnel.

Service Notes

1. Compressor components are shown in normal order

of removal from compressor (Fig. 21 and 22).

2. For replacement items, use Carrier specified parts.

See Carrier 5F,H Specified Parts list for compressor

part interchangeability.

3. Before servicing compressor, pump down the refrig

erant as follows:

a.

Start compressor, close suction service valve,

and reduce crankcase pressure to 2 psig. (Bypass

low pressurestat with jumper.)

b. Stop compressor; close discharge service valve to

isolate it from system.

c.

Bleed any residual refrigerant. Drain oil if

neeessary.

4. After disassembly, clean all parts with solvent. Use

mineral spirits, white gasoline or naphtha.

5. Before assembly, coat all parts with compressor oil

and clean and inspect all gasket surfaces. Replace all

gaskets with new, factory-made gaskets, and lightly

coat with oil. See Table 10 for torque values.

6.

After reassembly, evacuate compressor and open

suction and discharge valves. Restart compressor

and adjust refrigerant charge.

Lubrication System

OIL PUMP (For 5H120 and 126 compressors, manu

factured in 1969 or later, refer to Gear Rotor Type

Oil Pump.)

Drain oil below level of pump-end bearing head.

Remove bearing head. Complete end bell assembly must

be removed on 5H40, 46, 60, 66, 80 and 86 models. Check

oil-pump rotor for end play. Maximum allowable move

ment of rotor is 0.0025 in. (Table 11). If there is excessive

end play, reposition oil-pump bushing in bearing head as

described below.

Turn rotor; if there is more than a slight drag, remove

pump cover and disassemble oil pump. Check all parts

(Fig. 20, 23 and 24) for wear and damage. Inspect oil-

pump bushing for scoring. Replace hushing if scored. If

bearing head is scored, replace complete bearing head and

oil-pump assembly.

Oil-Pump Bushing Installation — Position bushing oil

groove at top when the bearing head is installed.

Machined

cireumferential

lines

mark

the

lead,

or

entering, end of the bushing. Press new bushing into the

pump-end bearing head from the inner side of the head

(Fig. 25 and 26).

Oil Pump Bushing Positioning (Fig. 25 and 26)

1. Place 0.001-in. cireular, field-fabricated shim against

bushing and install pump. (Shim between bushing and

oil pump rotor.)

(Continued on page 25.)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book

Tab

PC 111

Catalog No 530-526

2a

PrintedinUSA

Form5F,H-11SI

Pg 19

For replacement items use Carrier Specified Parts

2-86

Replaces: 5F,H-9SI