Pump-end main bearing (fig. 46), Pump-end main bearing, 5f,h open-drive compressors – Carrier 5F User Manual

Page 33

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

5F,H

Open-Drive Compressors

hot water or oil until heated to 180F or more. Remove

all traces of water before reassembly. Do not heat

impellers with torch.

INSPECTION — Check crankshaft journals for wear

and tolerances (Table 11). Remove crankshaft plugs,

check oil passages and clean if clogged.

Connecting-rod bearing inserts and main bearings are

available for crankshafts reground from .010-in. or

.020-in. undersize. A worn crankshaft suitable for

regrinding to above tolerances can be exchanged for a

factory-reground

crankshaft

and

bearings.

Factory-

reground crankshafts are stamped on both ends with an

A (.010-in. undersized) or B (.020-in. undersized).

IMPORTANT; Do NOT regrind crankshafts for

5H46, 66, 86, and 126 compressors in the field.

Replace shafts with scored journals.

All instructions for field grinding apply only to

standard-stroke crankshafts.

On crankshafts reground locally, hold throw to

1.001 in. for 5F compressors and to 1.376 in. on 5H com

pressors. Stamp A or B on crankshaft and pump-end

bearing head next to oil pressure gage connection.

To

determine

maximum

and

minimum

journal

diameters for undersized shafts, subtract the amount (in.)

that the shaft will be ground undersize from factory from

the tolerances specified in Table 11. For example, the

factory tolerance for 5H40 seal-end journal is 2.6225 in.

to 2.6235 inches. Tolerance for a crankshaft reground

to .010 in. undersize should therefore be held between

2.6125 in. and 2.6135 inches.

IMPORTANT:

When

regrinding

the

seal-end

journal on 5H120 crankshaft, do not grind in the

area of the oil separator impeller. This is not journal

area, and must remain intact or the oil separator

impeller will not fit properly.

REASSEMBLY — If 5H120 or 5H126 oil separator has

been removed, read impeller paragraph below before

installing crankshaft.

When regrinding crankshaft, remove crankshaft plugs

and clean oil passages as well. Before replacing crank

shaft, insert and tighten plugs, and reinstall the 5H120

and 126 oil separator impeller:

1. Insert dowel key (Fig. 29) with axis parallel to axis

of crankshaft. Position key so chamfered edge is

toward radius of crankshaft journal.

2. Immerse oil separator impeller in oil or hot water to

heat it to 180 F or more. If water is used, remove all

traces before reassembly. Install impeller on crank

shaft with dowel key lined up with impeller keyway.

Impeller must fit key snugly.

3. Check that seal-end thrust washer is in place on dowel

key in crankcase.

Insert crankshaft and install pump-end bearing head,

connecting rod and piston assemblies, valve plate and

cylinder heads. On 5H80, 86, 120 and 126 units, insert

center main bearing setscrew and lock screw as described

under Servicing Center Main Bearing. On 5H86, 120 and

126 units, reconnect oil line to center main bearing.

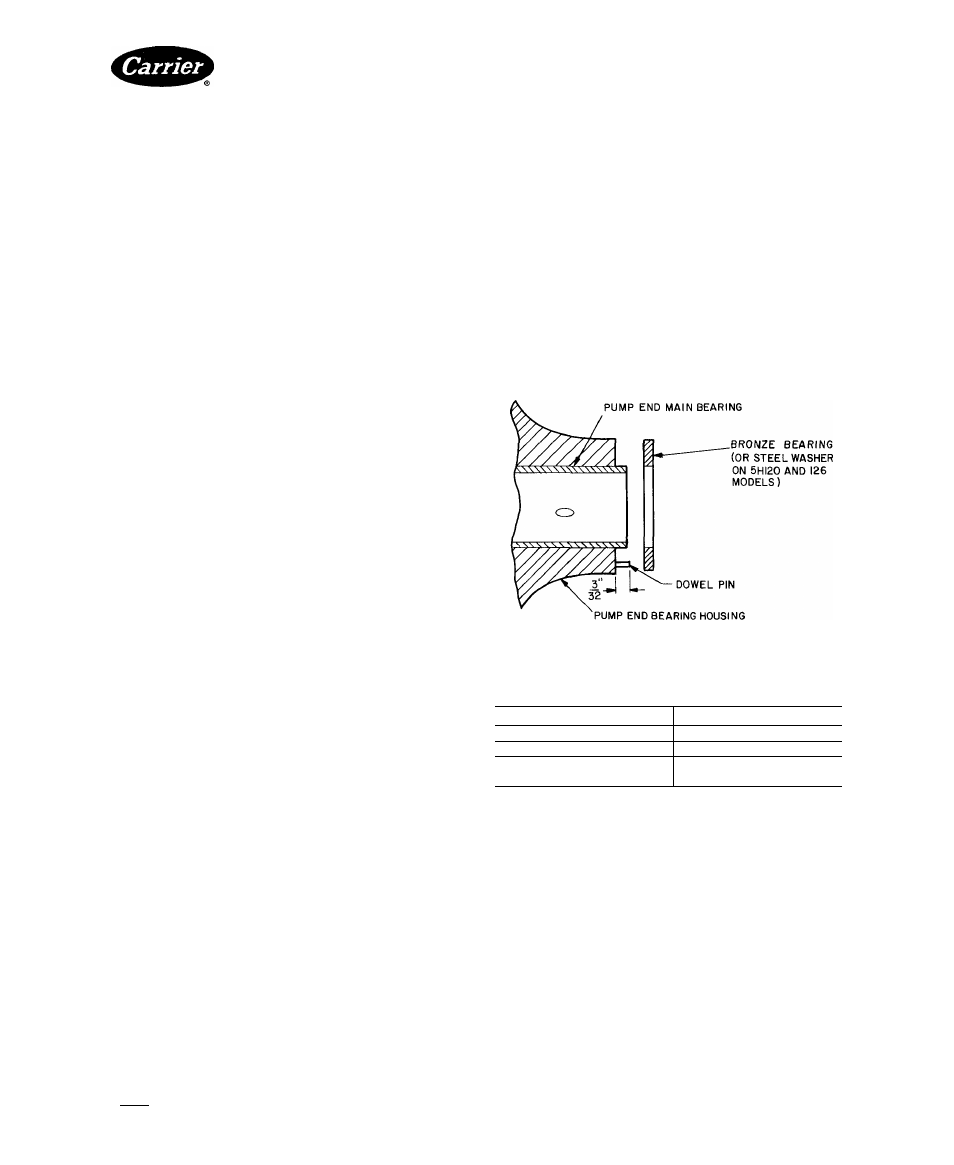

Pump-End Main Bearing (Fig. 46)

DISASSEMBLY AND INSPECTION — On 5H40, 46,

60, 66, 80 and 86 units, remove pump-end cover. Remove

pump-end bearing head on all units. Inspect bearing for

tolerances shown in Table 11. If a pump-end main bear

ing is worn, remove bronze bearing washer, and chisel out

bearing. Inspect bearing housing for wear (Table 11) and

damage. Remove any burrs.

REASSEMBLY

1. Lubricate outside of new bearing with heavy grease.

2. Line up hole in bearing with oil port in housing.

3.

Press bearing into place using a puller shoulder

(Table 12and Fig.47 and 48) andjack screw or bearing

press.

Place bearing washer on bearing with notch in washer

properly positioned around dowel pin (Fig. 46).

4.

Fig. 46 — Pump-End Main Bearing Position

Table 12 — Main Bearing Puller Sizes

COMPRESSOR

PULLER SIZE

5F20, 5F30

5F20

5F40, 5F60

5F40

5H40,46,60,66,

80,86,120,126

5H40

NOTES.

1. Bearing pullers are available from the Robin Air Mfg Co,

Montpelier, Ohio

2. Side of puller marked B is for undersized bearings.

Center Main Bearing — Size 5H80 through 5H126

compressors have a center main bearing and housing.

DISASSEMBLY AND INSPECTION — On 5H86, 120

and 126 compressors, disconnect oil line to center main

bearing. (5H80 center main bearings are fed through the

shaft.)

Remove plug on compressor crankcase (Fig. 44).

Then remove hollow lock screw beneath the plug (Fig.

45). Next, loosen hollow-cup setscrew until center main

bearing assembly can be slid from its support. Remove

crankshaft and bearing assembly.

Disassemble bearing (Fig. 45) and inspect for proper

tolerances (Table 11).

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|2

PC 111

Catalog No 530-526

PrintedinUSA

Form5F.H-11SI

Pg 33

2-86

Replaces; 5F.H-9SI

For replacement Items use Carrier Specified Parts.

Tab 2a