Capacity control inspection and service, 5f,h open-drive compressors – Carrier 5F User Manual

Page 31

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

5F,H

Open-Drive Compressors

UNLOADER

CYLINDER

BRACKET

GASKET

GASKET

(BOTTOM)

SPRING

RETAINER

PISTON WASHER

UNLOADER

CYLINDER

SPRING

GASKET

(MIDDLE)

(TOP)

UNLOADER

SPRING

(OUTER)

CYLINDER

COVER PLATE

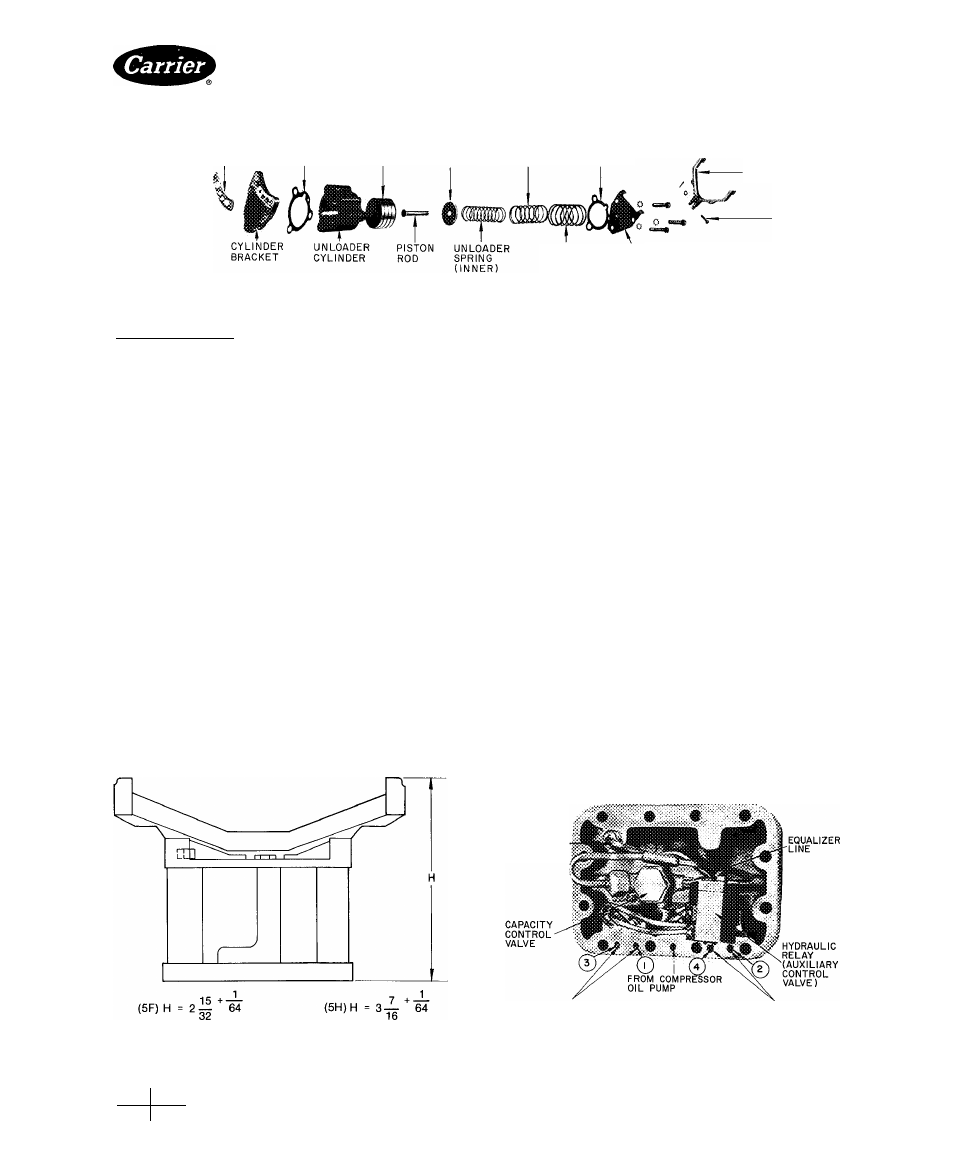

Fig. 39 — Unloader Power Element (Typical)

UNLOADER FORK

CLEVIS PIN

Unloaded Operation — A drop in suction pressure

decreases pressure against control valve bellows. Range

adjustment spring presses against the push pins, com

pressing the valve spring. This moves the needle valve

off the seat.

Control oil bleeds from hydraulic relay and control

valve to crankcase, relieving oil pressure on hydraulic

piston. The piston retracts, preventing transmission of

pressurized oil to controlled cylinder power element(s),

and the oil drains to crankcase.

As oil pump pressure on power element drops, the

piston moves downward. Lifting fork(s) pivot(s) upward,

moving lifting pins upward; suction valves rise from

their seats and controlled cylinder(s) unload(s). It should

be noted that a minimum of 33 to 35 pounds of oil pres

sure is required for proper unloader operation.

Capacity Control Inspection and Service

UNLOADER POWER ELEMENT REMOVAL

Remove cylinder head, valve plate, connecting rod,

piston and cylinder sleeve. Remove Allen head cap

screws (2) holding unloader power element in position.

Remove power element (Fig. 39) and disassemble.

Check all parts for wear or damage.

POWER

ELEMENT

REPLACEMENT

Check

un

loader fork height (Fig. 40) of new or assembled power

element.

Attach power element to internal suction manifold.

Replace cylinder sleeve piston, connecting rod, valve

plate, cylinder head and handhole cover.

EXTERNAL ADJUSTING STEM REMOVAL does

not require compressor to be pumped down. Loosen hex

nut at valve stem base and remove adjusting stem

assembly.

REMOVAL

OF

CAPACITY

CONTROL

VALVE

AND HYDRAULIC RELAY — Assembly is located

in handhole cover (Fig. 41) of 5F40 and 5F60 units;

in pump-end cover (Fig. 42) of 5H40, 46, 60, 66, 80,

and 86 units; and in pump-end bearing head (Fig. 43) of

5H120 and 126 units.

Remove capacity control valve and hydraulic relay.

NOTE; It is not practical to remove hydraulic relay from

5H40 through 5H86 compressors.

Inspect parts for wear, damage or evidence of leaking

or sticking.

A new handhole cover, pump-end cover or pump-end

bearing head with control valve assembly and hydraulic

relay may be installed. However, capacity control valve

(and hydraulic relay on 5H120 and 126 units) is available

as a separate parts item for installation on original

handhole cover, pump-end cover, or pump-end bearing

head.

INSPECT CONTROL OIL STRAINER — On 5F com

pressors, the control oil strainer is located on the side

of the pump-end bearing head (Fig. 23). Strainer is

located behind the control oil pressure gage connection

block on the 5H120 and 126 units (Fig. 20) and on pump-

end cover (Fig. 42) of all other 5H compressors.

Remove strainer and inspect it for holes and dirt. Clean

it with solvent and replace.

TO CONTROL

PRESSURE

GAGE CONN.

TO UNLOADER

POWER ELEMENTS

UNLOADER

WS

TO UNLOADER

POWER ELEMENTS

-

0

-

0

Fig. 40 — Unloader Fork Height (5F and 5H)

SEQUENCE

Fig. 41 — Compressor Handhole Cover and

Assembly (5F40 and 5F60)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book

2

PC111

Catalog No 530-526 Printed in U S A Form 5F.H-11 SI

Pg 31

2-86 Replaces: 5F,H-9SI

Tab

2a

For replacement Items use Carrier Specified Parts.