A warning, 5f,h open-drive compressors – Carrier 5F User Manual

Page 25

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HKATING ft COOLING

5F,H

Open-Drive Compressors

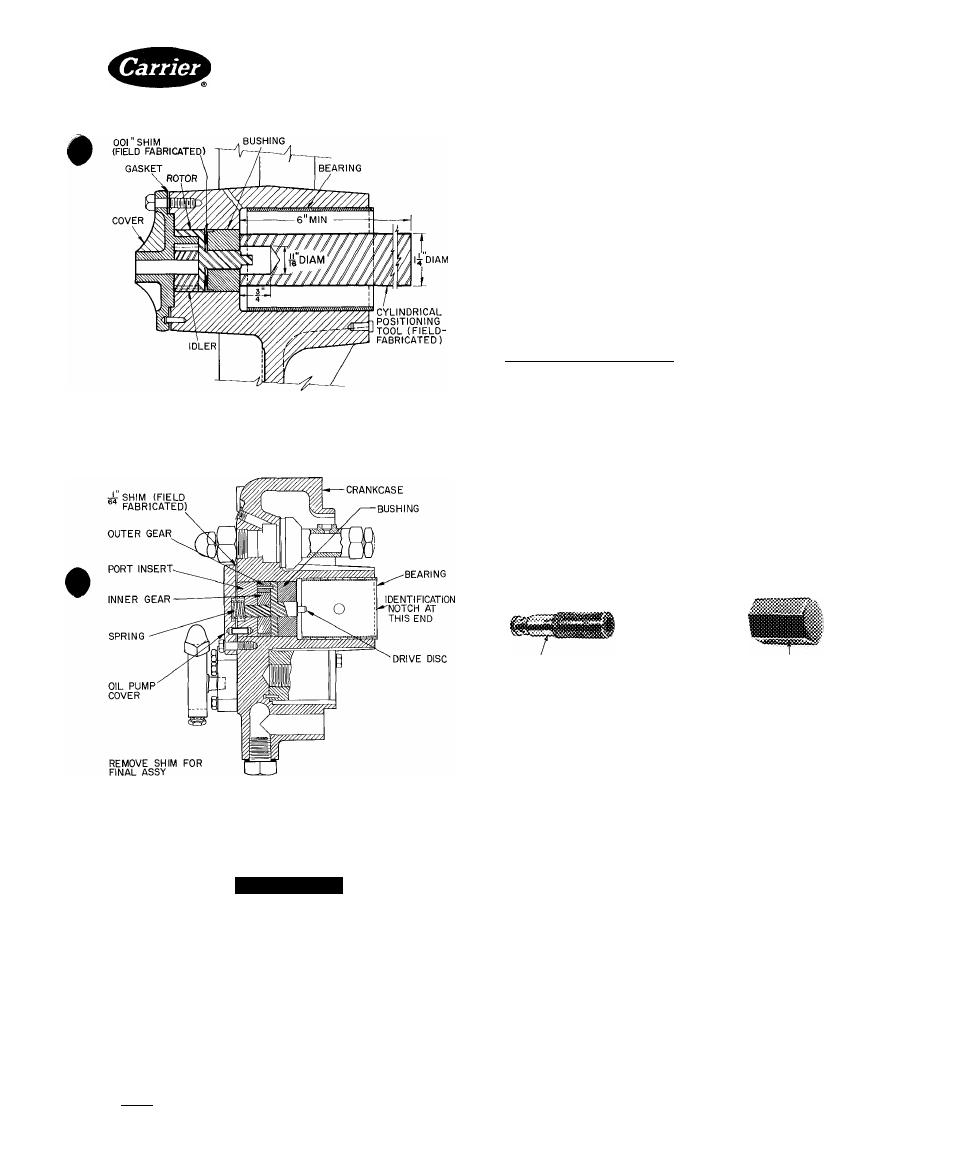

Fig. 25 — Setting Oil Pump Bushing

(Typical 5F20 through 5H86 —

5H40 Bearing Head Shown)

Fig. 26 — Setting Oil Pump Bushing

(Typical 5H120, 126)

2. Complete assembly of oil pump.

A

WARNING

Oil pump assembly must be flush with coverplate

surface, but must not protrude beyond bearing

head surface.

3. Tap bushing with a cylindrical positioning tool to

seat it against shim (Fig. 25 and 26).

4. Disassemble oil pump and remove shim.

5. Reassemble oil pump; check for binding.

6. Install bearing head on compressor. Line up tang on

oil-pump rotor shaft with slot in end of crankshaft.

Check oil pump for proper direction of rotation.

1. Refill compressor oil to proper level.

Observe oil pressure when starting compressor. If

correct pressure (Table 4) is not reached in 8 to 12

seconds, stop compressor and recheck oil pump.

GEAR ROTOR TYPE OIL PUMP (Models 5H120 and

126 manufactured from 1969 on) — Remove bearing

head and oil-pump cover (Fig. 20). Disassemble oil pump.

Check all parts for wear and damage. Inspect bushing for

scoring. Replace hushing if scored. If bearing head is

scored, replace complete bearing head and oil-pump

assembly.

Install New Oil-Pump Bushing — Reinstall oil pump into

bearing head with 1 / 64-in. shim between port insert and

oil-pump cover. Install oil-pump cover without gasket for

this operation. Press new bushing into bearing head from

inner side so that the bushing oil groove is at the top

when the bearing head is installed (similar to Fig. 26).

Machined circumferential lines mark the lead, or enter

ing, end of the bushing. Press on bushing until port insert

bottoms against the 1/64-in. shim. Remove pump cover

and shim. Reinstall pump cover with gasket and install

assembled bearing head on compressor. Check oil pump

for proper direction of rotation.

OIL PRESSURE REGULATING VALVE (nonadjust-

able, Fig. 27) is located on the side of compressor adjacent

to seal housing. Regulator maintains correct oil pressure

(Table 6) and ensures satisfactory unloader operation.

A.

OIL

REGULATING

VALVE BODY

GASKET

OIL

REGULATING

VALVE CAP

Fig. 27 — Oil Pressure Regulating Valve

(Nonadjustable)

Unscrew regulator from crankcase; use 5/ 16-in. Allen

wrench on all compressors except 5H120, which requires

1/2-in. Allen wrench. Regulator must not be clogged and

plunger must not be stuck. Check drillings to regulator

for fouling.

The nonadjustable oil pressure regulator is inter

changeable on all current 5F,H compressors except

5 H120 and 5 H126 models. 5 H120 and 5 H126 units have

larger,

nonadjustable

regulators.

Early

5F,H

com

pressors were equipped with an adjustable-type oil-

pressure regulator. When an adjustable-type regulating

valve needs replacing, use a nonadjustable regulator.

OIL RETURN CHECK VALVE (5F20 through 5H86)

allows oil to return from suction manifold to crankcase.

This normally open valve closes when crankcase pressure

becomes higher than suction pressure (Fig. 28).

Two disc-type check valves on 5F20 and 5F30 com

pressors are located beneath partition between suction

manifold and crankcase, one on each side of compressor.

Remove check valves through bottom cover or pump

end of eompressor.

Manufacturer reserves the right to discontinue, or change at any lime, specifications or designs without notice and without incurring obligations.

Book|2

PC 111

Catalog No 530-526

PrIntedInUSA

Form5F,H-11SI

Pg 25

2-86

Replaces: 5F.H-9SI

For replacement items use Carrier Specified Parts.

Tab 2a