Seal-end main bearing, Crankshaft seal inspection and replacement, Replacement – Carrier 5F User Manual

Page 34: 5f,h open-drive compressors

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

5F,H

Open-Drive Compressors

BEARING

PULLER

SHOULDER

N

DIRECTION OF PULL

•SEAL HOUSING

HOUSING PILOT

TOP PLATE

CRANKCASE BEARING HOUSING

Fig. 47 — Seal-End Main Bearing (5F40, 60)

1. Position bearing so chamfered edge enters bearing

housing first, oil holes in bearing and housing are

aligned, and bearing relief groove is at top.

2. Pull bearing into housing (Fig. 49). Edge of bearing

should be 1/32-in. below surface of bronze bearing

washer.

Look through oil pressure regulator opening to

check oil passage for blockage.

Blow out oil groove in bearing housing and oil lines

(if any) to it.

3.

Fig. 49 — Seal-End Main Bearing Positioning

REASSEMBLY — Install the new bearing inserts.

Assemble bearing housing on crankshaft, hut do not

tighten

the

hollow-cup

setscrew.

Install

crankshaft,

center main bearing and housing, and pump-end main

bearing assembly. Tighten bolts holding the pump-end

bearing assembly. Rotate crankshaft while tightening

setscrew on center main bearing housing. Setscrew should

tighten fully without any binding of crankshaft. If bind

ing occurs, shim the opposite side of bearing housing,

using .001-in. shim stock.

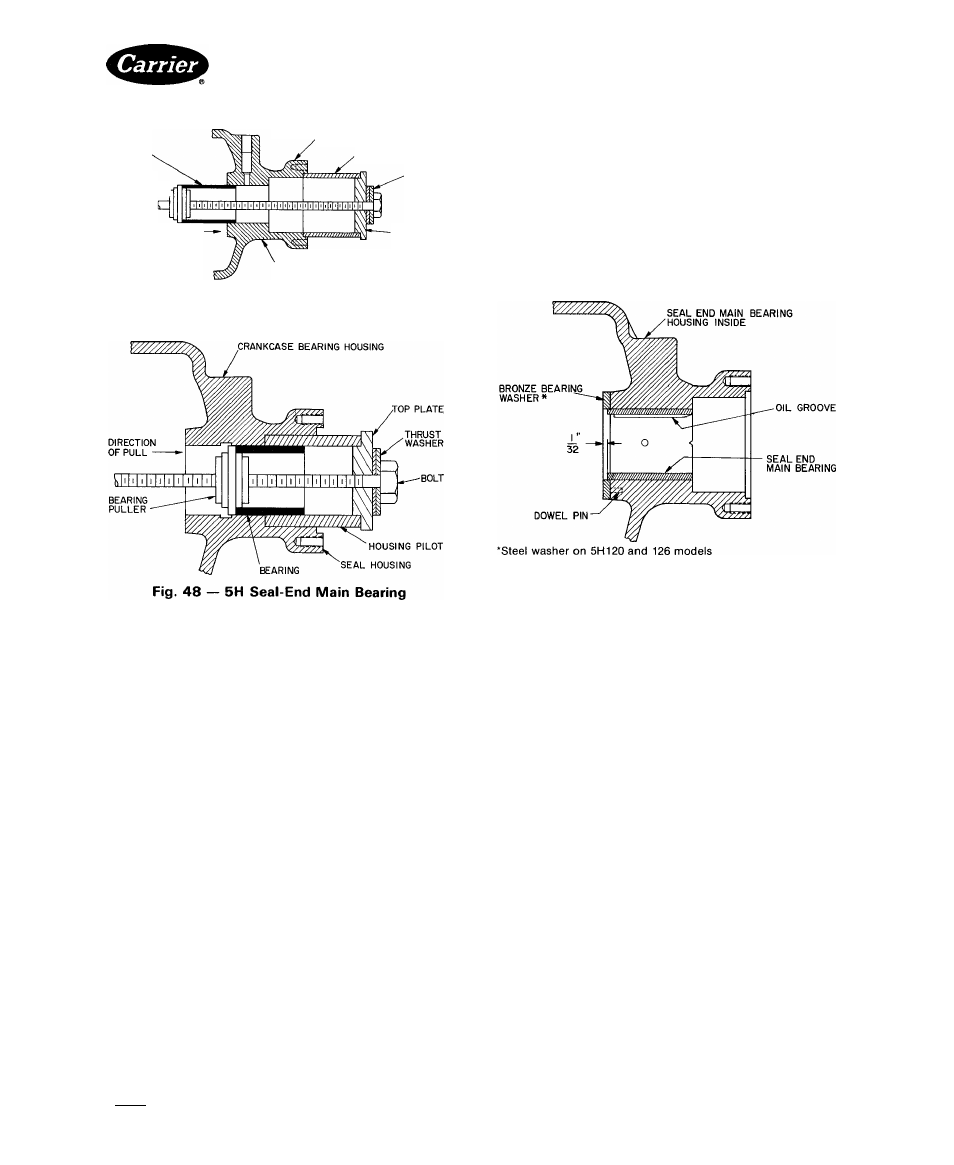

Seal-End Main Bearing

DISASSEMBLY AND INSPECTION — With crank

shaft removed, use a bearing puller with a shouldering

device to remove and install seal-end main bearings

(Fig. 47 and 48). Bearing pullers and sleeve pullers are

available from the Robin Air Manufacturing Company,

Montpelier, Ohio.

Inspect bearing and bearing housing for tolerances

shown in Table 11.

REASSEMBLY — Remove any burrs and clean bearing

housing before replacing bearing. Lubricate outside

of bearing with heavy grease.

Crankshaft Seal Inspection and Replacement

— The crankshaft seal in all current 5F,H compressors

is a rotating, bellows-type seal. This seal is the service

replacement for all earlier seal assemblies. Figure 50

shows Types I and II of this design (5F20 through 5H126

compressors).

IMPORTANT; Do not attempt to repair or replace

seal components. Replace complete seal assembly

with current rotating-bellows-type assembly. Do not

disassemble bellows assembly of service replace

ment seal.

BEFORE INSTALLING SEAL

1. Pump-end bearing head must be in place for proper

positioning of seal on crankshaft.

2. Be sure shaft extension and edges of keyway are free

of sharp edges and nicks. Also, shaft must be clean and

free of rust. Polish shaft with crocus cloth.

3. Check seal assembly for proper bellows placement

and cleanliness.

4. Apply compressor oil to seal assembly and crank

shaft, completely saturating bellows and carbon ring.

INSTALLATION — Refer to Fig. 51 for procedure.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book [2

PC 111

Catalog No 530-526

Printed i n U S A

Form5F,H-11SI

Pg 34

2-86

Replaces: 5F,H-9SI

Tab 12a

For replacement Items use Carrier Specified Parts.