A caution, 5f,h open-drive compressors – Carrier 5F User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

5F,H

Open-Drive Compressors

#

Step 5 — Install Multiple Compressors

EQUALIZING LINES — Compressors operating in

parallel require interconnecting lines for oil and gas

pressure equalization. Special handhole cover plates,

equipped with tapped holes for equalizing lines, are avail

able as options for sizes 5F40 and 5F60, as well as for

sizes 5H40, 46, 60, 66, 80, and 86 eompressors (Fig. 11).

An oil float system is an acceptable alternative to

equalizer lines.

5H120 and 126 Compressors include factory-supplied,

tapped cover plate. On these compressors, use only

lower connection for oil equalization (Fig. 11). Connect

gas equalizing line to flange connection shown. Mat

ing flange for 1-1/8 in. line is Carrier Part No.

DK24CA712 (Mueller Part No. A-5151); gasket Part No.

is DK29GA005 (Mueller Part No. A-5152).

GAS

EQUALIZER

CONNECTION

i

4"

od

flange

(5HI20-I26 ONLY!

OIL EQUALIZER

connection

l" IPS

GAS EQUALIZE

connection

Fig. 11 — Special Handhole Cover and

Equalizer Connections (Typical)

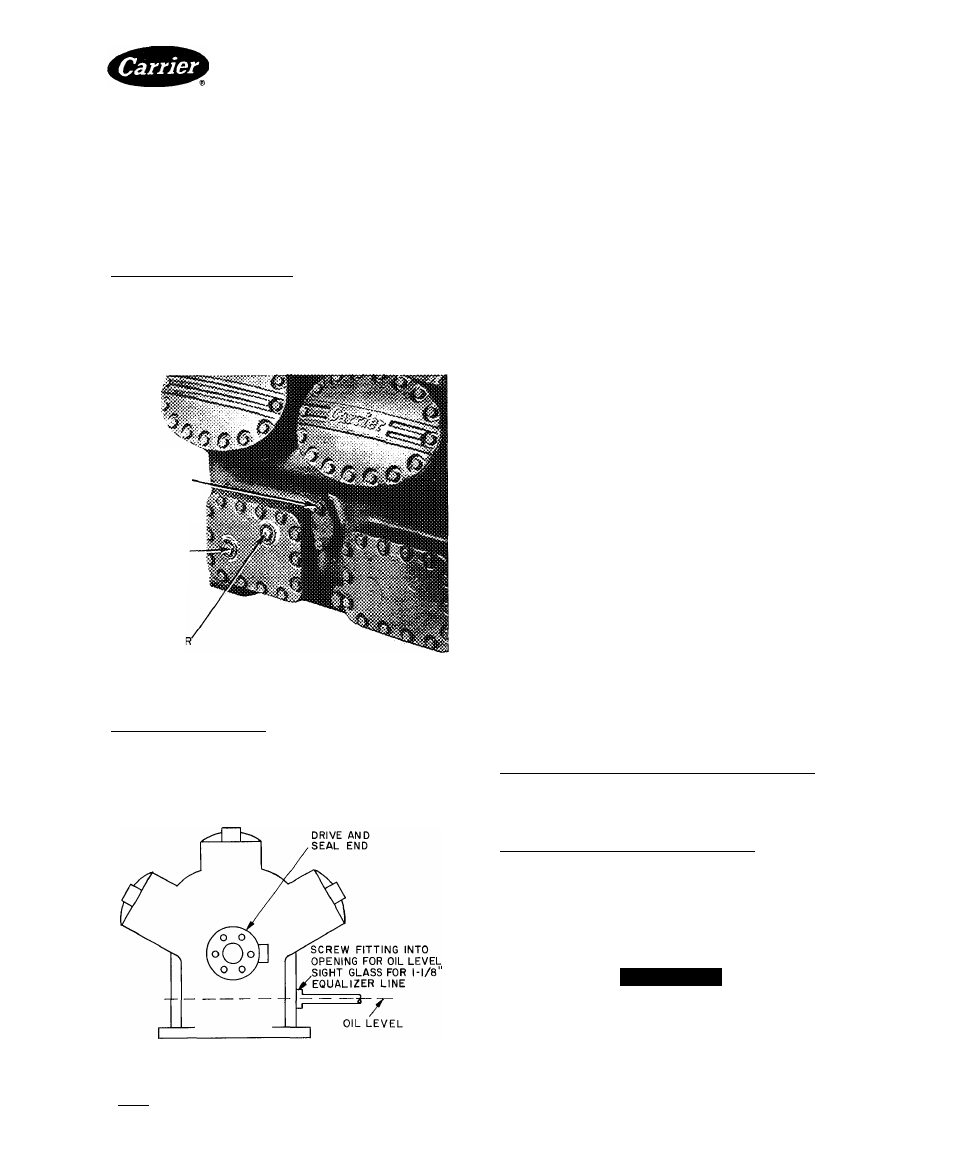

5F20 and 30 Compressors have no special tapped cover

plate. Use opening for oil sight glass to attach the I -1 / 8 in.

line for gas and oil equalization (Fig. 12). Accessory

Package No. 06DA900072 provides two I/8-in. line

adapters to thread into the sight glass opening. If addi

tional equalization is desired, run a 3/8-in. line to the oil-

filter plug connection (Fig. I and 2).

Fig. 12 — Equalizer Connections (5F20 and 5F30)

Step 6 — Make Electrical Connections

GENERAL NOTES

1. Factory wiring complies with National Electrical Code

(NEC). Any field modifications or additions must

comply with all applicable codes.

2. *For control circuit information, refer to Accessory

Control Panel Installation Instructions.

3. If control circuit power is supplied from a separate

source, rather than from a transformer, bring 115-v

power through a field-supplied, 15-amp disconnect,

in compliance with NEC Section 440-14 (disconnect

must be in sight from and readily accessible from

unit).

4. Open control-power disconnect only when servicing

unit.

Crankcase

heaters

must

remain

energized

when unit is not operating.

5. *Factory wiring is for single pumpout control. Do not

use pumpout control on equipment used with DX

coolers. Wiring label shows field connections used

with DX cooler.

6. *Contactor C2 is used with 208-v motors, 25 through

60 hp, and 460-v motors, 50 through 150 hp.

7.

*When field interlocks are used, remove jumpers

between terminals 3 and 4, and between terminals

7 and 8 on TB2.

♦Refers to compressor units and condensing units only.

ATTACH

POWER

WIRES

TO

COMPRESSOR

MOTOR — Attach power wires in accordance with

motor manufacturer’s instructions and in compliance

with NEC and applicable local codes.

CHECK MOTOR ROTATION — Before connecting

motor to compressor, check direction of motor rotation.

Rotation must be in same direction as that indicated by

arrow on compressor pump cover (or on plate attached

near pump-end bearing housing). If direction is not the

same, reverse motor rotation by reversing any 2 power

leads to motor.

If rotation of oil pump is reversed, reverse direction of

pump rotation arrow as well. At that time make the

following adjustments:

All 5F Compressors and 5H120and 126 Compressors —

Remove 6 cap screws from oil pump cover (Fig. 1-4, 8).

Do not damage gasket. Rotate cover 180 degrees and

replace. Arrow at top of oil cover will indicate new direc

tion of rotation.

5F40, 46, 60. 66. 80 and 86 Compressors — Drain oil

below level of pump-end dome cover (Fig. 5-7). Remove

pump-end cover to expose oil pump cover in center of

main bearing housing. Rotate oil pump cover 180 degrees

and replace it. Replace pump-end cover and reverse

external arrow to match new direction of rotation. Proper

direction can later be checked without removing pump-

end cover.

A CAUTION

If the special gasket between oil pump cover and

oil pump is damaged, replace with correct gasket

only. Check oil pressure immediately after starting

compressor.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

BookI 2

PC 111

Catalog No 530-526

PrintedinUSA

Form5F,H-11SI

Pgll

2-86

Replaces: 5F.H-9SI

For replacement items use Carrier Specitled Parts

Tab 2a