A caution, Cylinder head and valve assemblies, Cylinder and unloader sleeves – Carrier 5F User Manual

Page 27: 5f,h open-drive compressors

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

5F,H

Open-Drive Compressors

detachable suction manifold and suction line. Withdraw

2 suction strainers.

Clean strainer with solvent or replace if broken or

corroded. When replacing suction strainer, do not

damage it.

On 5H120 and 126 compressors, positioned manifold

cover plate must compress strainer bail. If bail is too

short, grasp on sides and elongate it enough to be com

pressed by manifold cover. Position bail between the 2

bosses on inside of manifold cover to prevent strainer

from turning.

A

CAUTION

If a felt sock filter is installed, remove and inspect it

after 50 hours of operation. Clean filter if required

and replace it for another 50 hours. Clean the suction

strainer whenever the felt sock is removed. Remove

sock when system is clean. (Not applicable for 5F20

and 30 compressors.)

DISCHARGE VALVE

SPRING

VALVE LIFTER

SPRING-

DISCHARGE VALVE

INNER SEAT

DISCHARGE VALVE

OUTER SEAT

SUCTION VALVE

IN PLACE

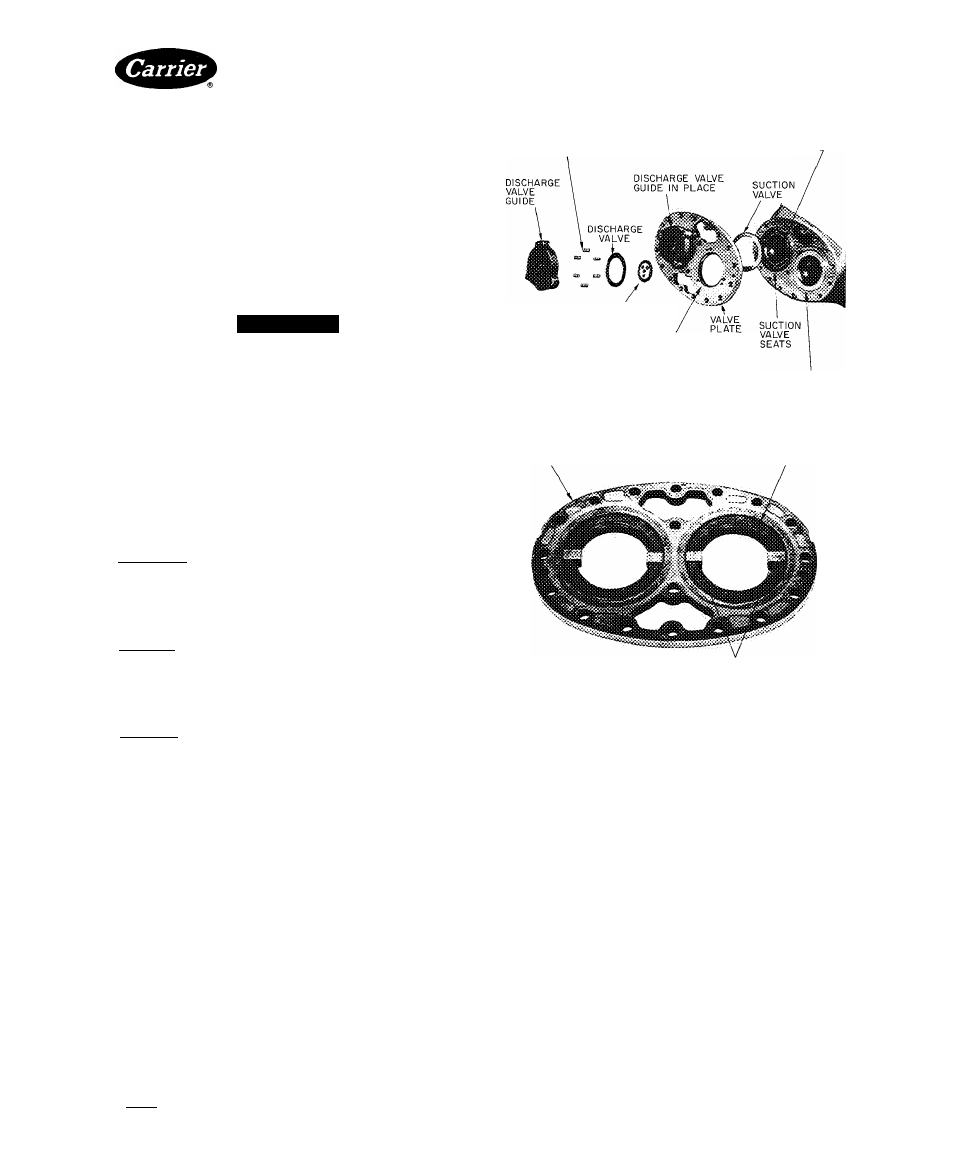

Fig. 32 — Suction and Discharge Valve Assembly

Cylinder Head and Valve Assemblies

CYLINDER HEAD INSPECTION — Remove cylinder

heads and check heads for warping, cracks and damage

to gasket surfaces.

VALVE INSPECTION (Fig. 32)

Disassembly — Remove cylinder head. Loosen cap

screws holding discharge valve seat to discharge valve

guide, and cap screws holding valve guide to valve plate.

Remove cap screws holding valve plate to cylinder block.

Remove valve plate from cylinder block and discharge

valve guide from valve plate.

Inspeetion — Inspect suction and discharge valve discs

and valve seats for craeks or excessive wear (Table 11).

Check cylinder-sleeve valve stops for uneven wear.

Replace valves if cracked or worn. If valve seats are worn,

replace complete valve plate assembly. If cylinder-sleeve

valve stops are worn, replace sleeve.

Reassembly — Pistons must be below tops of cylinder

sleeves. To position correctly, turn crankshaft or force

pistons down.

1. Place suetion valve springs in valve plate recesses.

Large

spring

coil

should

be

in

full

contact

with bottom of recess.

2. Place suction valve disc on valve springs; press disc

into valve plate recess. Slide valve retainer elips into

place (Fig. 33). Clips must not cover valve lifter

springs or pins. Valve retainer clips 5F20-2061 (5F

compressors) and 5H40-2061 (5H eompressors) are

field supplied.

3. Bolt valve plate to cylinder block. Remove valve elips.

4. Place discharge valve springs in diseharge valve guide

spring recesses.

5. Place diseharge valve dise over springs, and fit inner

spring in place over valve disc. Hand-tighten bolts

holding inner seat to valve guide (valve guide

assembly).

6. Place valve guide assembly on valve plate. Tighten all

bolts and bend tabs on lock washer and lock plates.

Replace cylinder head.

VALVE PLATE

SUCTION VALVE DISC

SUCTION VALVE RETAINER CLIPS

Fig. 33 — Valve Clips in Place

Cylinder and Unloader Sleeves

DISASSEMBLY (Fig. 35) — Remove cylinder head,

suction and discharge valve assembly, and pump-end

bearing head. Whenever cylinder sleeve or valve plate is

replaced, use a new suction valve disc.

1. Turn crankshaft until piston is in midposition.

2. Insert a sleeve puller into cylinder and push it down

onto top of piston.

3. Tighten nut on top of sleeve puller to expand puller

in sleeve.

4. Turn crankshaft, forcing sleeve upward until it can

be removed.

5. Remove unloader snap rings (5H eompressors only).

Disassemble unloader sleeve, pins and springs.

INSPECTION — Examine bore of sleeve for wear.

Check suction valve seats for scratches and wear. Check

unloader sleeves, pins and springs for wear and freedom

of movement (Table 11).

REASSEMBLY — When new rings are being installed in

a used cylinder sleeve, break the hard, glazed surfaee

of eylinder sleeve to reduce wearing-in period of new

rings. Clean sleeves thoroughly after breaking glaze.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

BookI 2

PC111

Catalog No 530-526

Printed in U.S A.

Form5F,H-11SI

Pg 27

2-86

Repiaces: 5F,H-9SI

Tab

I

2a

For replacement items use Carrier Specified Parts.