0 clearances and dimensions, 1 clearances – Reznor SC Duct Furnace Unit Installation Manual User Manual

Page 5

Form I-SC, P/N 207696 R11, Page 5

Application

Option Shipped Separate Components

Heating -- Gas Control AG7

Thermostat,

P/N 48033

Makeup Air -- Gas

Control Options

(NOTE: If an optional

remote console

is ordered, the

control switch and

temperature selector

may be mounted on the

console.)

AG3

Control Switch,

P/N 29054

AG8

Control Switch,

P/N 29054; Sensor & Mixing Tube,

P/N 48041

AG9

Control Switch,

P/N 29054; Remote Temperature

Selector,

P/N 48042; Sensor & Mixing Tube, P/N 48041

AG15

Control Switch,

P/N 29054; Remote Temperature

Selector,

P/N 115848; Stage Adder Module, P/N

115849; Discharge Air Sensor Holder, P/N 115850;

Discharge Air Sensor Holder Bracket,

P/N 213612

AG39 Remote Temperature Selector, P/N 174849;

Temperature Sensor,

P/N 133228; Mixing Tube,

P/N 90323

Some gas control options will have parts either shipped loose with the heater or

shipped separately. If your unit is equipped with any of the gas control options in the

table below, be sure these parts are available at the job site.

Other shipped-separate

options could include a gas

shutoff valve, a vertical vent

terminal, a thermostat, an

optional control, and/or a

disconnect switch.

Check to see if there are

any field-installed options

that need to be assembled

to the furnace prior to

installation.

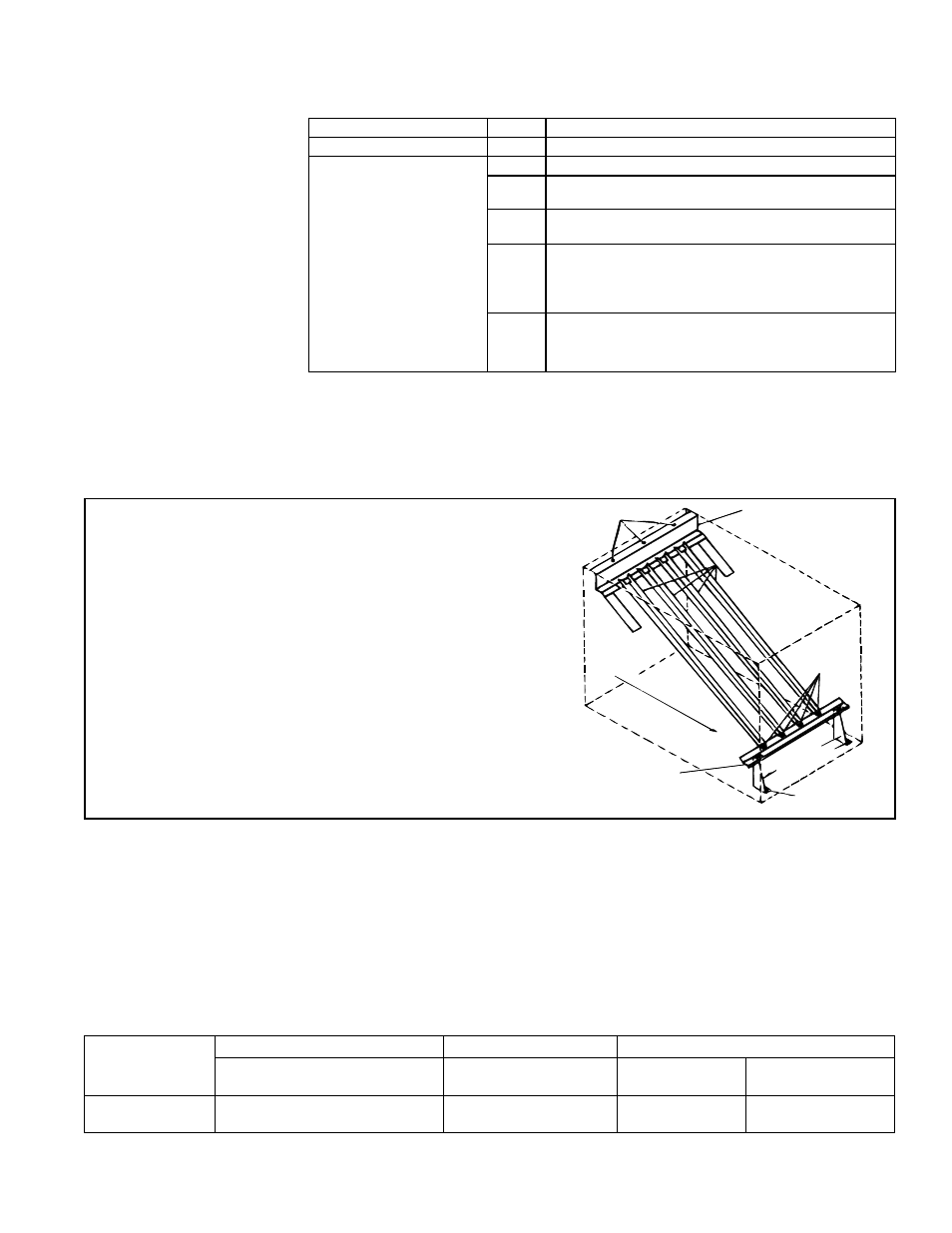

Top Baffle

Support

Screws B

Bottom

Baffle Support

Bracket

s

Air Discharge

Direction of

Airflow

Screw C

Right

Lef

t

Screws A

Screw C

FIGURE 1 - Model SC Heat Exchanger Baffles

3.2.2 Reversing

Airflow by Changing

Direction of Heat

Exchanger Air Baffles

Instructions for Reversing Airflow through the Heat

Exchanger

1.

Remove screws "A". Lift each baffle slightly and slide forward,

removing each completely from the heat exchanger.

2. Remove screws "B" and the rear top baffle support

assembly. Re-position the assembly on the opposite end

of the heat exchanger and attach.

3. Remove screws "C" and the assembled bottom baffle

support and brackets. Plug the holes in the heat

exchanger bottom by re-inserting the screws in the holes.

Position the assembly on the opposite end of the heat

exchanger and attach using field-supplied sheetmetal

screws.

4. Re-install all of the individual baffles by reversing Step 1.

Option Parts

All furnaces are equipped with directional air baffles in the heat exchanger area. Fac-

ing the control compartment of the furnace, the standard direction of airflow is from left

to right. If the installation requires airflow from right to left (when facing the control com-

partment), the position of the directional air baffles may be reversed. Refer to

FIGURE

1 and follow the instructions to reverse the direction of the airflow through the furnace.

4.0 Clearances

and

Dimensions

4.1 Clearances

For safety and convenience, provide clearances as shown in the following table.

Clearance to combustibles is defined as the minimum distance from the heater to a

surface or object that is necessary to ensure that a surface temperature of 90°F above

the surrounding ambient temperature is not exceeded. Minimum clearances are also

listed on the heater rating plate.

Minimum Clearances - inches (mm)

Top

Sides

Bottom

Control Side

Side Opposite

Controls

To

Combustibles

To Non-

Combustibles

6" (152mm)

6" (152mm) plus width of unit

6" (152mm)

6" (152mm)

0" (0mm)