0 controls (cont'd), 4 gas controls (cont'd) – Reznor SC Duct Furnace Unit Installation Manual User Manual

Page 30

Form I-SC, P/N 207696 R11, Page 30

Combustion Air

Pressure Switch

Settings - Options

AG39 and AG40

Sensor Location -

Options AG39

Description of

Operation of Option

AG39

Carryover

Regulator

Modulating

Valve

Single-

Stage Gas

Valve

P rimary Gas

Flow Pressure

Switch

White Label

1.1 w.c.

Gas Flow

Pressure Switch

White Label

1.1 w.c.

8.4.4 Optional

Electronic Modulation

(cont'd)

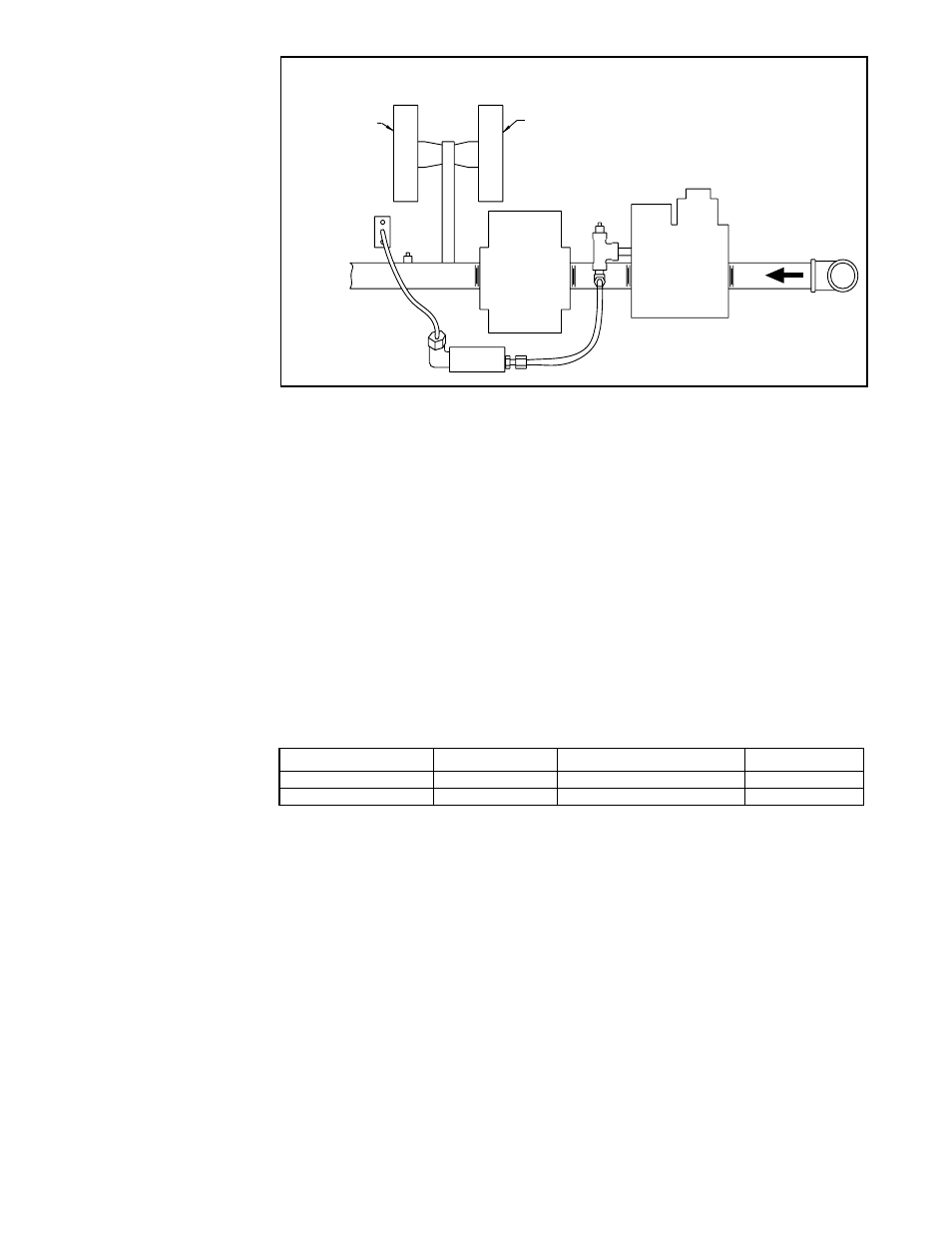

FIGURE 30 - Option AG39 Manifold Arrangement

Note: Arrangement may vary slightly

depending on gas valve; components

are the same.

This uniquely designed modulation system requires combustion air pressure settings

different from the standard system. The approximate settings for the combustion air

proving switch at sea-level operation are:

Sizes with AG39&40

Startup Cold

Equilibrium at Full Rate

Factory Setting

100-225

-1.3"w.c.±0.2

-1.05"w.c.±0.1

-1.0"w.c.±0.02

250-400

-1.2"w.c.±0.2

-0.95"w.c.±0.1

-.70"w.c.±0.05

The duct temperature sensor is shipped loose for field installation. See Paragraph

6.4.5 for determining the sensor location. I

Wiring and Service-

Options AG39 and

AG40

For wiring, consult the wiring diagram attached to the furnace. All wires in the electri-

cal box connecting the modulation controls must have a temperature rating of 150°C.

This is a unique system which includes custom-built components and custom settings.

If service is required, follow the general troubleshooting guide on page 37 and the

special troubleshooting guides in

FIGURE 31.

The gas supply (see pressure requirements in the table above) connects to the single-

stage gas valve. To compensate for additional pressure loss through the modulating

valve, the single-stage gas valve has a custom outlet pressure setting higher than

when it is used on a standard gas manifold. The pilot tubing connects to the pilot port

on the single-stage gas valve. When the valve receives a call for heat from the ampli-

fier and pilot is established, gas flow from the single-stage valve goes to both the mod-

ulating valve and the regulated lighter tube system. When the signal from the amplifier

to the modulating valve requires less-than-high fire operation, the modulating valve

functions to lessen the gas flow to the burner to reduce the input rate to that required to

maintain the desired temperature. When the input rate is reduced enough to decrease

the gas pressure to 1.1" w.c., the primary gas pressure switch in the manifold activates

the gear motor that controls the bypass damper in the venter/combustion air system.

The bypass damper opens diverting some of the incoming air directly into the flue duct,

reducing airflow through the burner. Safety switches monitor the position of the bypass

damper. When the gas pressure increases above 1.1" w.c., the bypass damper closes.

8.0 Controls

(cont'd)

8.4 Gas Controls

(cont'd)

Computer Controlled

Electronic Modulation

between 20-28% and

100% Firing Rate,

Option AG40

- not

available on Size 350;

natural gas only

With this option the furnace is equipped with a Maxitrol signal conditioner (see illustra-

tion in

FIGURE 29B) which accepts an input signal of either 4-20 milliamps or 0-10 volts

from a customer-supplied control device such as a computer. With the dip switches on

the conditioner in the "on" positions, the conditioner accepts a 4-20 milliamp signal. In

the "off" positions, the conditioner accepts a 0-10V signal. The conditioner converts

the signal to the 0 to 20 volt DC current required to control the modulating valve.

The heater functions and is equipped in the same way as described for Option AG39

except that with computer control, the temperatures are selected through the software

and there is no temperature selector or duct sensor.