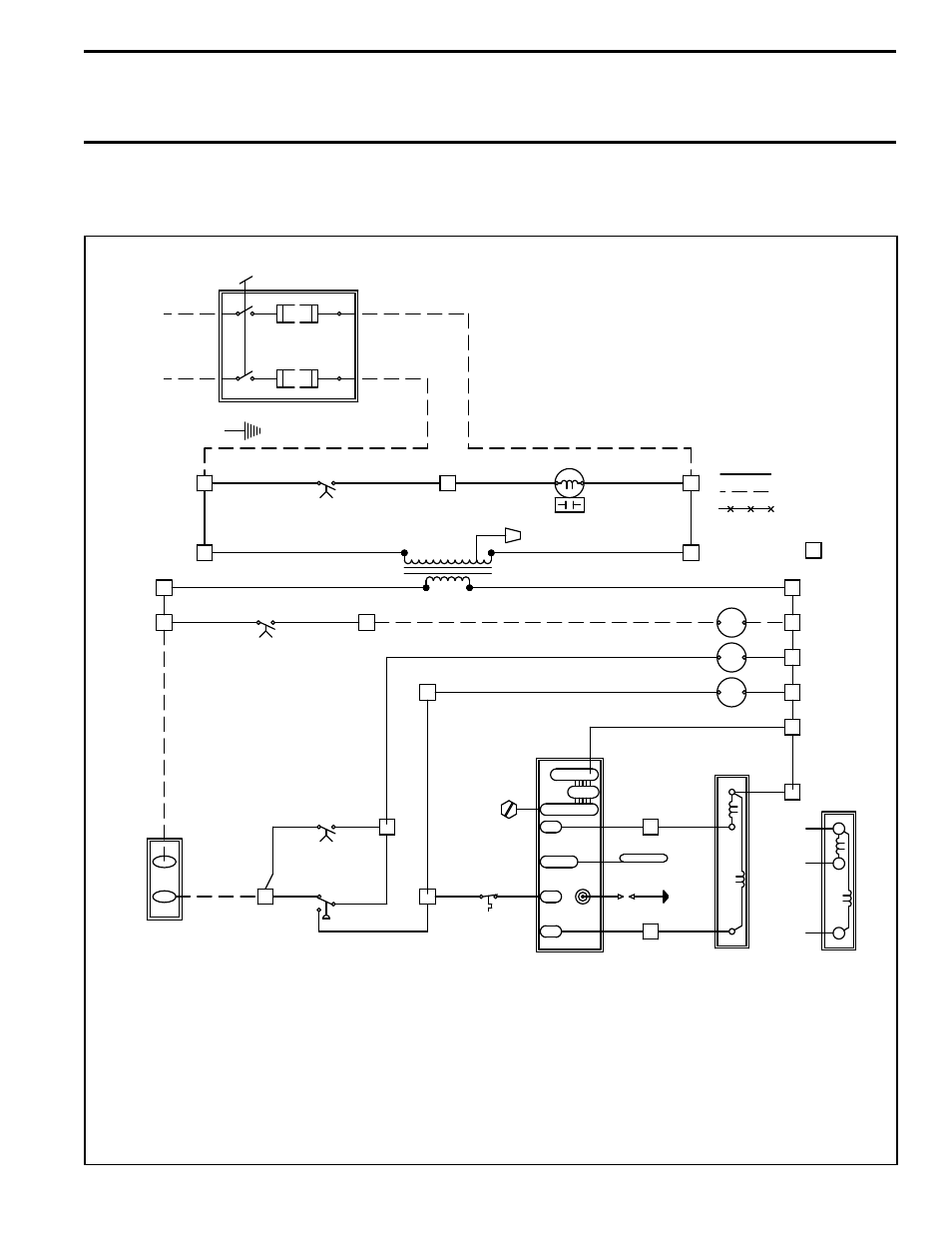

3 typical wiring diagrams, Sc: ah2/ah3, Figure 24 - model sc with single-stage gas control – Reznor SC Duct Furnace Unit Installation Manual User Manual

Page 25

Form I-SC, P/N 207696 R11, Page 25

CAUTION: If any of the original wire as supplied with the appliance must be replaced, it

must be replaced with wiring material having a temperature rating of at least 105°C, except

for sensor lead and optional bypass damper combustion air safety circuit (Option AG39 or

AG40) wires which must be 150°C. See Hazard Levels, page 2.

7

8

9

10

11

12

19

20

21

22

23

24

25

26

27

28

29

30

RELAY CONTACTS

TIME DELAY

& CAPACITOR

VENTER MOTOR

B

C

W

8

12

1

2

RELAY CONTACTS

TIME DELAY

4

11

2

R

Y

W

BK

W

BK

BK

BK

7

7

BK

BR

24

H

TD

H

BR

W

23

H

TD

H

BR

7

W

TIME DELAY

RELAY COIL

12 - 28

22

FAN

CONTROL TD

CR

22

7

BLOWER RELAY COIL

CUSTOMER'S 24 VOLT

8 VA. MAXIMUM

FACTORY WIRING

FIELD WIRING

WHITE - W

PURPLE - PR

BLUE - BL

GREEN - G

YELLOW - Y

ORANGE - O

RED - R

BROWN - BR

BLACK - BK

WIRING CODE

TOTAL WIRE MINIMUM RECOMMENDED

LENGTH WIRE SIZE

150 FEET #18 GA.

250 FEET #16 GA.

350 FEET #14 GA.

FIELD CONTROL WIRING

BK

BK

Y

BR

7

DISCONNECT SWITCH

LINE/1/60

GRD

G

40 VA. CONTROL

TRANSFORMER

BK

Y

BL

BR

R

B

W

LIMIT

CONTROL

SWITCH

PRESSURE

COMBUSTION

NC

NO

COM

LINE VOLT

24V

10

Y

BL

R

OPTIONAL FACTORY

WIRING

8

BL

WD 126093 REV. #9

1, 2, 4, 7, 8, 10, 11,

12, B, C & W

TERMINAL

BLOCK --

HEATER

COMPARTMENT

SC: AH2/AH3

7

BR

BK

BL

SET ANT

. A

T 1.0 AMPS

OPTIONAL

SINGLE

ST

A

GE THERMOST

AT

R

W

MAIN

PILOT

OPERATING SEQUENCE

- SET THERMOSTAT AT LOWEST SETTING.

- TURN ON POWER, MAIN AND PILOT MANUAL GAS VALVES.

- SET THERMOSTAT AT DESIRED SETTING.

- ON A CALL FOR HEAT BY THE THERMOSTAT

- THE VENTER MOTOR IS ENERGIZED AFTER A 15 SECOND (APPROX.) TIME DELAY.

- VENTER FLOW SWITCH SWITCHES FROM N.C. TO N.O. CONTACTS ENERGIZING

THE PILOT GAS VALVE AND SPARK TO PRODUCE A PILOT FLAME ON EACH

OPERATING CYCLE. THE SENSING PROBE PROVES THE PRESENCE OF THE PILOT

FLAME AND ENERGIZES THE SAFETY PORTION OF THE CONTROL. THE SWITCH

ACTION DE-ENERGIZES THE SPARK GAP AND ENERGIZES THE MAIN VALVE.

THE MAIN GAS IGNITES AND UNIT FIRES AT LOW RATE.

- SET THERMOSTAT AT LOWEST SETTING FOR SHUTDOWN.

ON 115/460V. UNITS THE CONTROL TRANSFORMER IS A SINGLE VOLTAGE PRIMARY.

- ON 208/230V. UNITS THE CONTROL TRANSFORMER HAS A DUAL VOLTAGE PRIMARY.

- USE #14 GA. WIRE FOR LINE WIRING ON UNIT.

TO PREVENT VOLTAGE DROP BEYOND FIVE PERCENT OF SUPPLY LINE VOLTAGE.

- LINE AND BLOWER MOTOR BRANCH CIRCUIT WIRE SHOULD BE OF A SIZE

- DOTTED WIRING AND THE FOLLOWING CONTROLS ARE SUPPLIED AND INSTALLED BY OTHERS: STARTER COIL

- THE FOLLOWING CONTROLS ARE FIELD INSTALLED OPTIONS: THERMOSTAT

- THE FOLLOWING CONTROLS ARE FACTORY INSTALLED OPTIONS: FAN CONTROL

FOR 115/460V. UNITS USE BLACK AND YELLOW LEADS.

FOR 208V. UNITS USE BLACK AND RED LEADS (CAP YELLOW).

FOR 230V. UNITS USE BLACK AND YELLOW LEADS (CAP RED).

- USE #18 GA. WIRE FOR 24 VOLT CONTROL WIRING ON UNIT.

NOTES

- CAUTION: IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE APPLIANCE MUST BE REPLACED, IT MUST

BE REPLACED WITH WIRING MATERIAL HAVING A TEMPERATURE RATING OF AT LEAST 105°C, EXCEPT FOR

SENSOR LEAD WIRE WHICH MUST BE 150°C.

- BLOWER MOTOR OPERATES FROM FAN TIME DELAY.

(SEE NOTES)

REDUNDANT

GAS V

AL

VE

AL

TERNA

TE

W

.R.

OR R

OBER

TSHA

W

BL

P

BK

BR

MAIN

PIL

O

T

M

C

OR PV

TH-TR

TH OR

TR OR

PV-MV

PIL

O

T

MV

MAIN

HONE

Y

WELL

REDUNDANT

GAS V

AL

VE

USE DUAL ELEMENTS TIME DELAY FUSES AND SIZE ACCORDING TO 1.25

TIMES THE MAXIMUM TOTAL INPUT AMPS.

- WHEN PROVIDING OR REPLACING FUSES IN THE FUSIBLE DISCONNECT SWITCH

- DISCONNECT SWITCH IS FIELD FURNISHED OR AVAILABLE FROM FACTORY AS AN OPTION.

BK

BL

BK

IGNITION

CONTROLLER

PROBE

GRND

SPARK

FLAME SENSING

MV/PV

MV

SENSE

TH

PV

G

BURNER

GND

BR

Y

- BLOWER MOTOR REMAINS ON AS DETERMINED BY FAN TIME DELAY.

CONTACTS

FAN TD

1

3

R

24V GND

GND BURNER

- IF THE FLAME IS EXTINGUISHED DURING MAIN BURNER OPERATION,

THE SAFETY SWITCH CLOSES THE MAIN VALVE AND RECYCLES THE

SPARK GAP.

ON UNITS EQUIPPED WITH LOCKOUT CONTROL, IF PILOT IS NOT

ESTABLISHED WITHIN 120 SEC. THE UNIT LOCKS OUT FOR ONE

HOUR, UNLESS IT IS RESET BY INTERRUPTING POWER TO

THE CONTROL CIRCUIT. (SEE LIGHTING INSTRUCTIONS)

M3(1)

M4(3)

M1(4)

M2(5)

7.3 Typical Wiring Diagrams

FIGURE 24 - Model SC with Single-Stage Gas Control