2 duct furnace blower connection, Warning, Figure 19a - straight through air – Reznor SC Duct Furnace Unit Installation Manual User Manual

Page 21: Figure 19b - with elbows up or down, Figure 19c - with elbows left or right

Form I-SC, P/N 207696 R11, Page 21

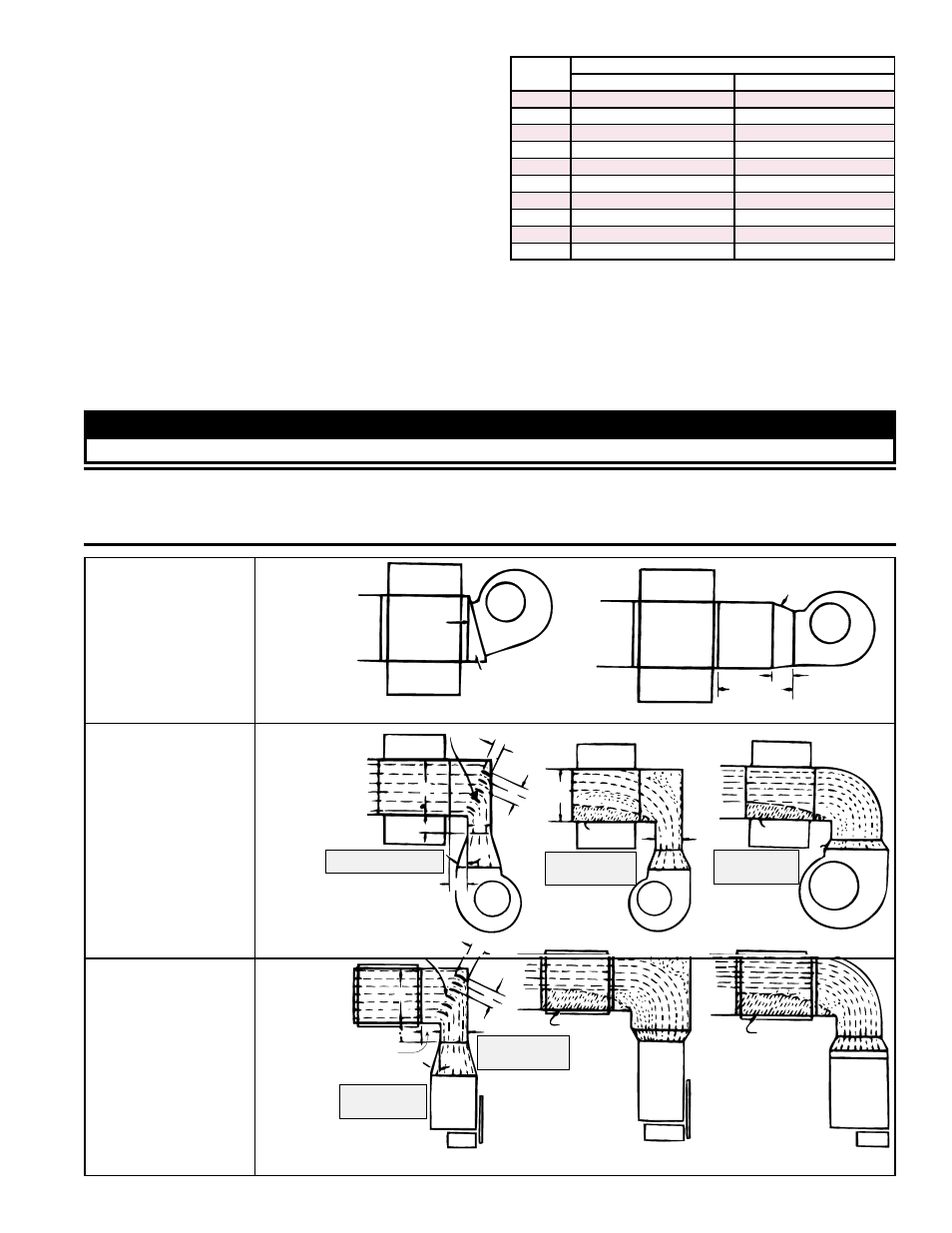

6.4.2 Duct Furnace

Blower Connection

Proper air arrangement of blower and duct furnace with respect to angle of approach

of the duct connection and the arrangement of the discharge opening of the blower are

shown in

FIGURE 19. Blowers should be bottom horizontal discharge when coupled

to the duct furnace. When a top horizontal discharge blower is connected to the duct

furnace, be sure that sufficient length of duct is provided to permit an even flow of air

at the furnace. Or, insert baffles between the blower and the heater to assure an even

flow of air across the heat exchanger.

Direct

Coupling

Slanted Transition

Suggested blower connections for straight through airflow. Use

either method for good air coverage and efficient operation.

15°

6 (152mm)

Remote

24

(610mm)

minimum

Turning Vanes

3

(76mm)

3(76mm)

3(76mm)

6 (152mm)

6 (152mm)

X

15°

Y

No air

X

No air

Z

NOTE: X should

never be less than 1/2 Y

NOTE: X should

never be less

than 1/2 Y

NOTE: Angle Z

should never be

more than 15°

Turning Vanes

3

(76mm)

3(76mm)

3(76mm)

6 (152mm)

6 (152mm)

Z

NOTE: Angle Z

should never be

more than 15°

X

15°

No air

No air

GOOD

GOOD

POOR

POOR

POOR

POOR

Y

Y

NOTE: X should

never be less than

1/2 Y

FIGURE 19A -

Straight

Through Air

vanes should be used in elbows or turns in the air inlet

to ensure proper air distribution (See Paragraph 6.4.2).

If it is determined that the blower CFM is greater than

allowed or desirable, see Paragraph 6.4.3 for instruc-

tions on determining the correct size of bypass duct

required.

Or, if a higher CFM is required through the furnace

within the limits in the chart on the right, install the high

CFM conversion kit, P/N 263309, that was shipped with

the unit.

Model

SC Size

High Air Throughput (CFM) with Kit, P/N 263309

MAXIMUM

MINIMUM

100

3700

980

125

4630

1230

150

5555

1480

175

6480

1725

200

7405

1975

225

8330

2220

250

9255

2465

300

11110

2960

350

12900

3455

400

14815

3950

FIGURE 19B -

With Elbows

Up or Down

WARNING

The furnace must be installed on the positive pressure side of the air-circulating blower.

CAUTION: Abrupt angle approaches such as shown in FIGURES 19B and 19C can be

detrimental to unit life. Be certain that ample air is directed at the base of the tube section

by using turning vanes as shown. See Hazard Levels, page 2.

Direct

Coupling

Slanted Transition

Suggested blower connections for straight through airflow. Use

either method for good air coverage and efficient operation.

15°

6 (152mm)

Remote

24

(610mm)

minimum

Turning Vanes

3

(76mm)

3(76mm)

3(76mm)

6 (152mm)

6 (152mm)

X

15°

Y

No air

X

No air

Z

NOTE: X should

never be less than 1/2 Y

NOTE: X should

never be less

than 1/2 Y

NOTE: Angle Z

should never be

more than 15°

Turning Vanes

3

(76mm)

3(76mm)

3(76mm)

6 (152mm)

6 (152mm)

Z

NOTE: Angle Z

should never be

more than 15°

X

15°

No air

No air

GOOD

GOOD

POOR

POOR

POOR

POOR

Y

Y

NOTE: X should

never be less than

1/2 Y

FIGURE 19C -

With Elbows

Left or Right