Reznor SC Duct Furnace Unit Installation Manual User Manual

Page 11

Form I-SC, P/N 207696 R11, Page 11

4) Joints and Sealing

Provide pipes as specified in

Requirement No. 1, pages 9-10, and seal joints as fol-

lows:

•

If using Category III vent pipe run, follow the pipe manufacturer’s instructions for

joining and sealing Category III vent pipe sections.

•

If using single-wall vent pipe run, secure slip-fit pipe connections using

sheetmetal screws or rivets. Seal all joints with aluminum tape or silicone sealant.

•

To seal joints in the single-wall combustion air pipe, secure slip fit pipe

connections using sheetmetal screws or rivets. Seal all joints with aluminum tape

or silicone sealant.

•

To seal joint in the terminal section of double-wall vent pipe (allowed

ONLY ABOVE the concentric pipes on a VERTICAL vent, follow the pipe

manufacturer’s instructions for joining and sealing double-wall vent pipe sections.

•

When joining the terminal section of double-wall vent pipe to the vent cap,

follow the illustrated step-by-step instructions in

FIGURE 6.

When joining the terminal section of double-wall vent pipe to a single-wall

or Category III vent pipe run, follow the illustrated step-by-step instructions in

FIGURE 7.

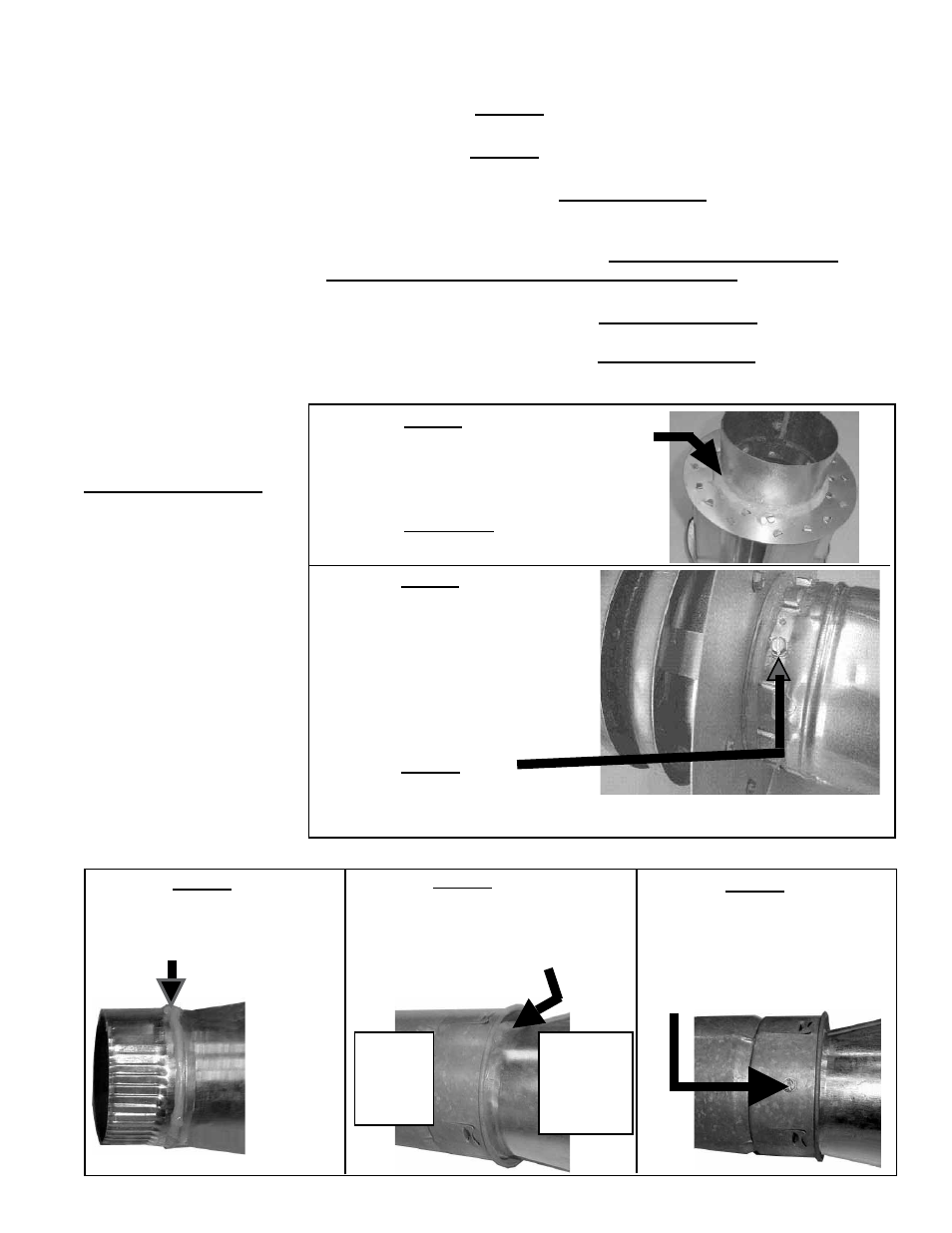

FIGURE 6 - Follow

STEPS to join Double-

Wall (Type B) Pipe and

the Vent Terminal Cap

(horizontal or vertical)

Figure 6 - STEP 1

Place a continual 3/8” bead of silicone sealant

around the circumference of the vent cap col-

lar. This will prevent any water inside the vent

cap from running down the double-wall pipe.

Do STEP 2 immediately following STEP 1.

Figure 6 - STEP 2

Insert the collar on the vent cap inside

the inner wall of the double-wall pipe.

Insert as far as possible. Add addi-

tional silicone sealant to fully close

any gaps between the vent cap and

the double wall pipe. This is neces-

sary to prevent water from entering

the double wall pipe.

Secure the vent cap to the double-wall

pipe by drilling and inserting a 3/4” long sheetmetal screw into the vent cap collar.

Do not overtighten screw.

Figure 6 - STEP 3

(NOTE: Pipes and vent

caps may not look exactly

as shown in the illustrations.

Instructions apply to both

horizontal and vertical vent

kits.)

FIGURE 7 - Follow

STEPS to join the

Double-Wall (Type B)

Pipe to the Taper-type

Reducer that Joins it

to the Single-Wall or

Category III Vent Run

Figure 7 - STEP 1

On the taper-type reducer, place a

continual 1/4” bead of silicone seal-

ant around the circumference.

Figure 7 - STEP 2

Insert the collar of the reducer into the

inner pipe of the double-wall pipe until

the bead of sealant contacts the inner

pipe creating a sealed joint.

Figure 7 - STEP 3

Spaced equally around the double-

wall pipe, drill three small holes

below the sealant ring. Insert 3/4

inch long sheetmetal screws to

secure the joint. Do not overtighten

screws.

Make this connection a maximum of 6" (152mm) from the concentric adapter box.

6" to 5"

or 7" to

5" Taper-

Type

Reducer

Do STEP 2

immediately

following

STEP 1.

5" I.D.

Double-

Wall

Pipe