Troubleshooting – AERCO KC Series Equipped with C-More Controller for Massachusetts Only User Manual

Page 69

TROUBLESHOOTING

7-6

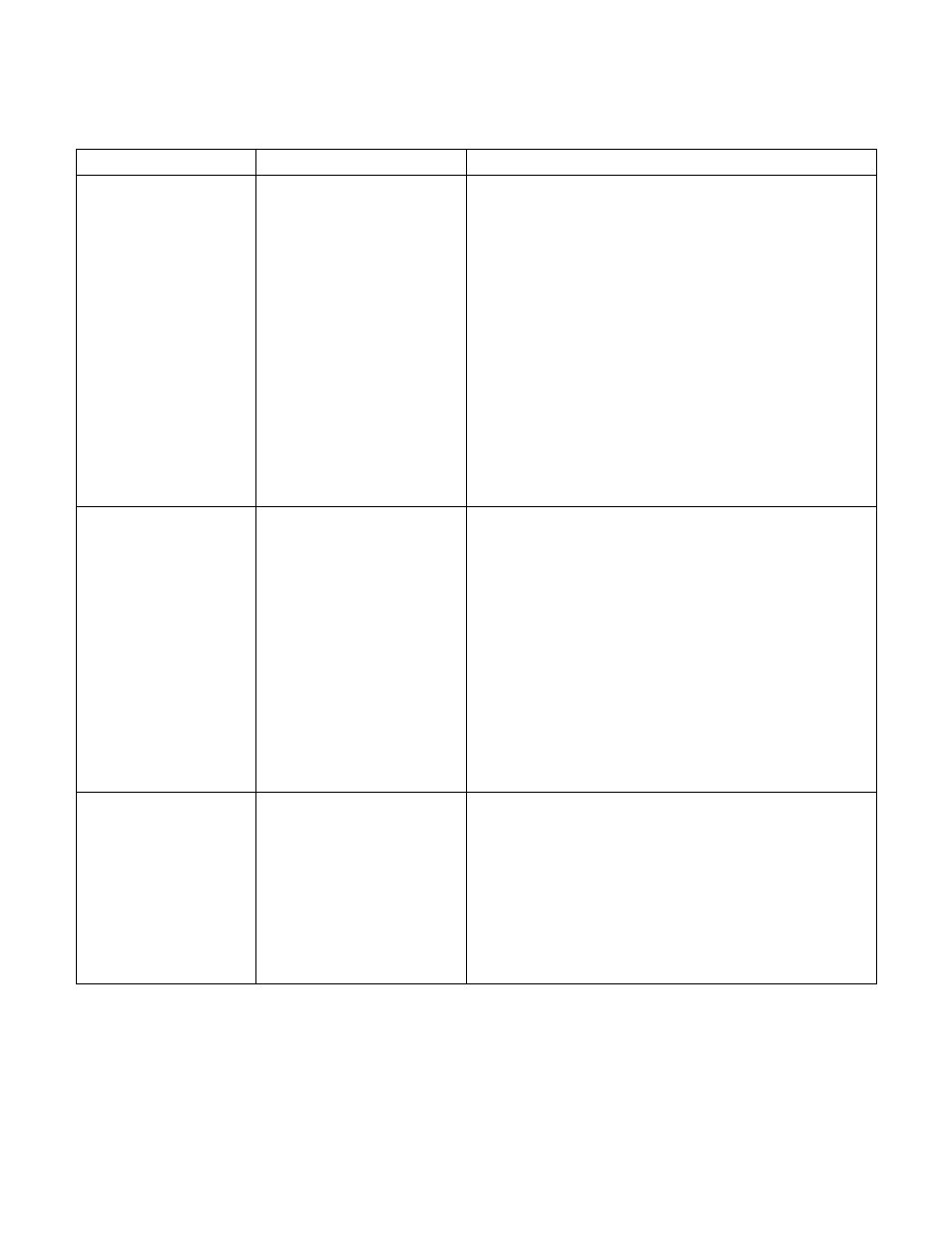

KC1000 WATER HEATER TROUBLESHOOTING TABLE – Continued

FAULT INDICATION

PROBABLE CAUSES

CORRECTIVE ACTION

IGN SWTCH CLOSED

DURING PURGE

1. Air/Fuel Valve not

rotating

2. Defective or shorted

switch

3. Switch wired incorrectly

4. Defective Power Supply

Board or fuse

5. Defective IGST Board

1. Start the unit. The Air/Fuel Valve should rotate to the

purge (open) position. If the valve does not rotate at all

or does not rotate fully open, check the Air/Fuel Valve

calibration. If calibration is okay, the problem may be

in the Air-Fuel Valve or the Control Box. Refer to

qualified service personnel.

2. If the Air/Fuel Valve does rotate to purge, check the

ignition switch for continuity between the N.O. and

COM terminals. If the switch shows continuity when

not in contact with the cam replace the switch.

3. Check to ensure that the switch is wired correctly

(correct wire numbers on the normally open terminals).

If the switch is wired correctly, replace the switch

4. Check DS1 & DS2 LEDs on Power Supply Board. If

they are not steady ON, replace Power Supply Board.

5. Check “Heartbeat” LED DS1 and verify it is blinking

ON & OFF every second. If not, replace IGST Board.

IGN SWTCH OPEN

DURING IGNITION

1. Air/Fuel Valve not

rotating to ignition

position.

2. Defective ignition switch

3. Defective Power Supply

Board or fuse

4. Defective IGST Board

1. Start the unit. The Air/Fuel Valve should rotate to the

purge (open) position, then back to ignition position

(towards closed) during the ignition cycle. If the valve

does not rotate back to the ignition position, check the

Air/Fuel Valve calibration. If calibration is okay, the

problem may be in the Air/Fuel Valve or the Control

Box. Refer fault to qualified service personnel.

2. If the Air/Fuel Valve does rotate to the ignition position,

check the ignition position switch for continuity

between the N.O. and COM terminals when in contact

with the cam.

3. Check DS1 & DS2 LEDs on Power Supply Board. If

they are not steady ON, replace Power Supply Board.

4. Check “Heartbeat” LED DS1 and verify it is blinking

ON & OFF every second. If not, replace IGST Board.

INTERLOCK

OPEN

1. Interlock jumper not

installed or removed

2. Energy Management

System does not have

boiler enabled.

3. Device proving switch

hooked to interlocks is

not closed.

1. Check for a jumper properly installed across the

interlock terminals in the I/O box

2. If there are two external wires on these terminals

check any Energy Management system to see if they

have the units disabled (a jumper may be temporarily

installed to see if the interlock circuit is functioning).

3. Check that proving switch for any device hooked to the

interlock circuit is closing and that the device is

operational.