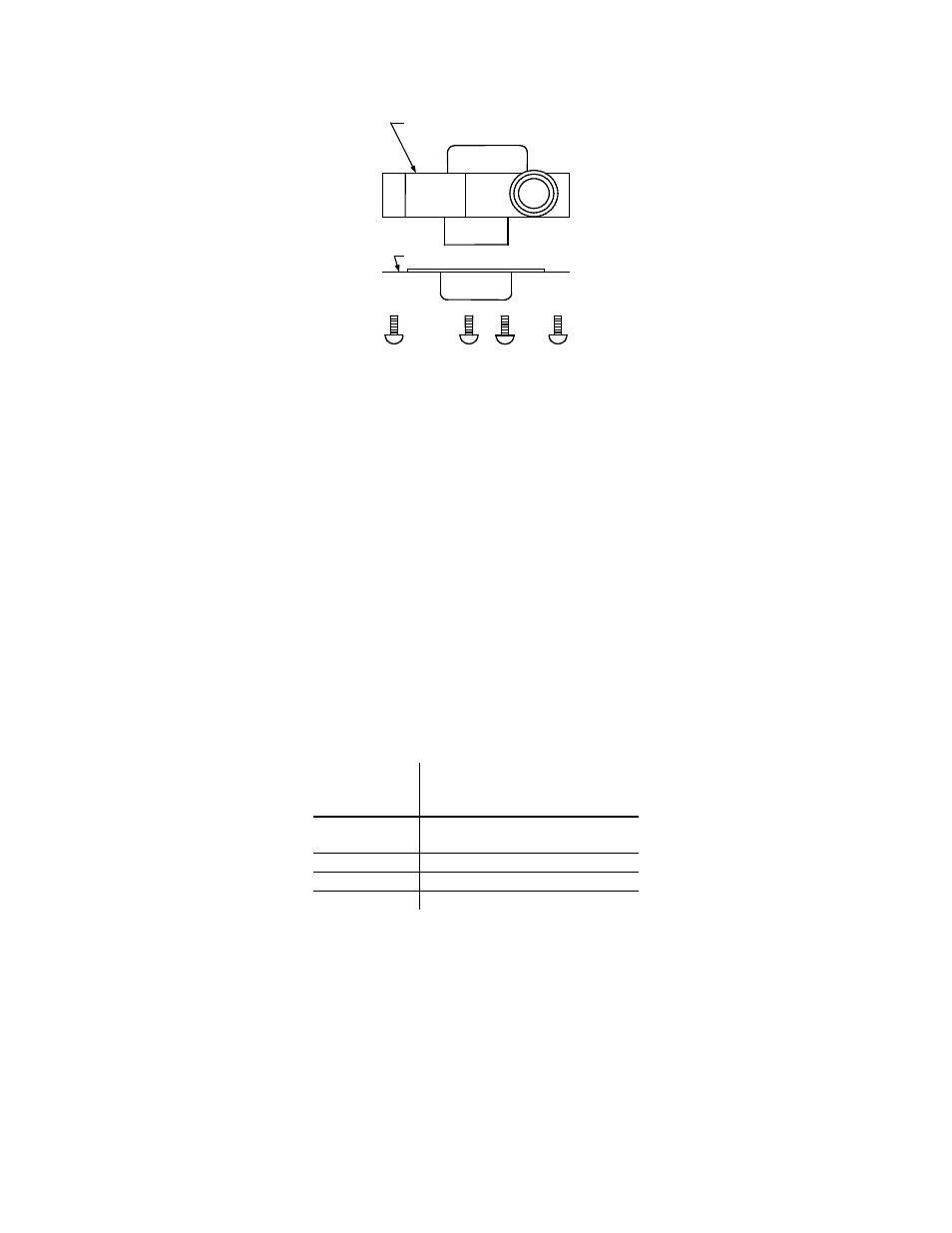

Figure 6.9, Impeller housing disassembly, 8 manifold and exhaust tubes – AERCO KC Series Equipped with C-More Controller for Massachusetts Only User Manual

Page 51: Maintenance

MAINTENANCE

6-7

IMPELLER HOUSING

COVER

Figure 6.9

Impeller Housing Disassembly

19. Once the BTU transmitter has been inspected and cleaned, reassemble in the reverse order.

NOTE:

Do not attempt to adjust the Hydraulic Zero Needle Valve. This is a factory-preset item. Refer to

Figure

6.5. If setting has been tampered with or BTU transmitter is being replaced, see procedure in Section

6.12, page 6-17.

NOTE:

Compression fittings are nickel-plated and should be replaced only with nickel-plated fittings. Do not use

brass fittings

.

6.8 MANIFOLD AND EXHAUST TUBES

The presence of even trace amounts of chlorides and/or sulfur, in the combustion air and fuel sources,

can lead to the formation of deposits on the inside of the exchanger tubes, the exhaust manifold, and/or

the condensate cup. The degree of deposition is influenced by the extent of the condensing operation and

the chloride and sulfur levels that vary significantly from application to application.

The following parts will be necessary for reassembly after inspection:

GP-122537

Exhaust Manifold to

Combustion Chamber

Gasket

GP-18900

Manifold to Tubesheet

Gasket

GP-18899

Burner Gasket

GP-122551

Burner Release Gasket

GP-161151

Combustion Chamber Liner

To remove the manifold for inspection:

1. Disconnect AC power and turn off the gas supply to the unit.

2. Remove the sheet metal covers from the unit.

3. Disconnect the plastic tubing from the condensate cup to drain and remove the rear covers.

4. Remove the condensate cup from under the unit and the condensate drainage tubing from the

manifold.

5. Disconnect the flame detector and ignition cable wires from the flame detector and ignitor contactor.

Remove the flame detector and ignitor as per paragraphs 6.2, and 6.3.