Maintenance – AERCO KC Series Equipped with C-More Controller for Massachusetts Only User Manual

Page 57

MAINTENANCE

6-13

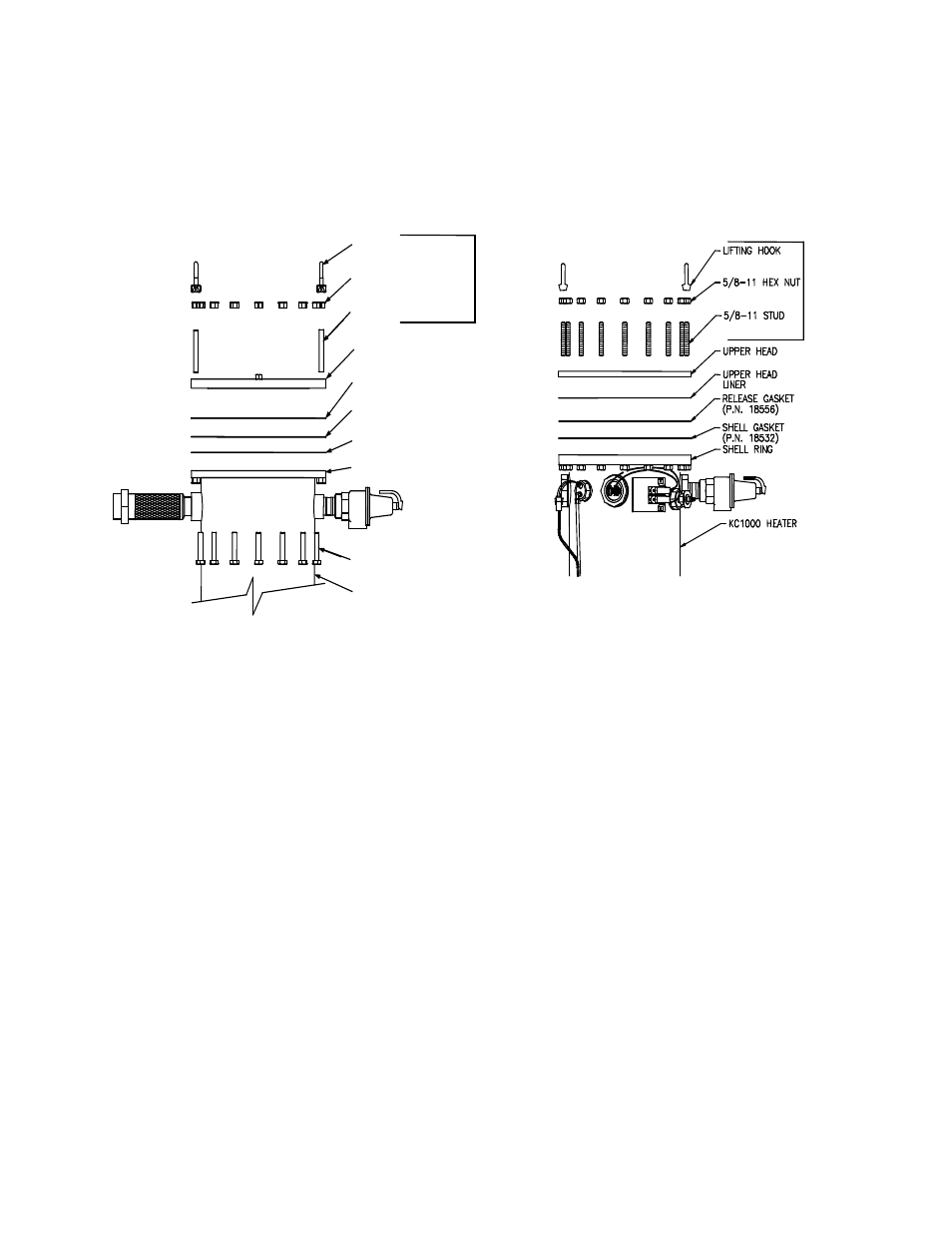

10. Reassemble the cap screws and nuts through the upper head and shell ring. Cross tighten the nuts to

approximately 75 ft./lb. torque to obtain a uniform seating, then progressively tighten the nuts to 150

ft./lb.

11. Replace the unit Cap. Close the drain valve and reopen the inlet, outlet, and recirculation valves to

refill the unit.

5/8-11 HEX NUT

5/8-11 X 3" CAP SCREW

KC1000 SS HEATER

5/8 EYE NUT

5/8-11 X 4-1/2" STUD

UPPER HEAD

(P.N. 18842)

UPPER HEAD LINER

RELEASE GASKET

(P.N. 18556)

SHELL GASKET

(P.N. 18532)

SHELL RING

Cleaning the Heat Exchanger

Precautions:

Please review MSDS, specifications, and our website

www.aerco.com

for additional information, or call

technical service at (800) 526-0288.

N

OTICE

Mix the HydroSkrub with an equal volume of water to obtain a 50% concentration (11.5 gallons of each =

23 gallons total).

N

OTICE

If the isolation valves are located more than one foot from the supply and return ports of the exchanger,

add in the piping volume from the exchanger to the valves.

CAUTION!

Do not drain the unit without venting the shell! A vacuum in the unit may displace the liner causing serious

damage not covered by warranty.

Figure 6.18b

Carbon Water Heater Head

Configuration

Figure 6.18a

SS Water Heater Head

Configuration

5/8-11 x 4-1/2” STUD

MOUNTED IN THREADED

HOLE

Do not

remove

if using a

chain

hoist

Do not

remove

if using a

chain

hoist

5/8-11 x 3” BOLT

MOUNTED IN

THRU-HOLE