5 electrical supply, Figure 2.7, Ac power box location – AERCO KC Series Equipped with C-More Controller for Massachusetts Only User Manual

Page 16: 1 electrical requirements, Figure 2.8, Ac power wiring diagram, 6 field control wiring, Installation

INSTALLATION

2-6

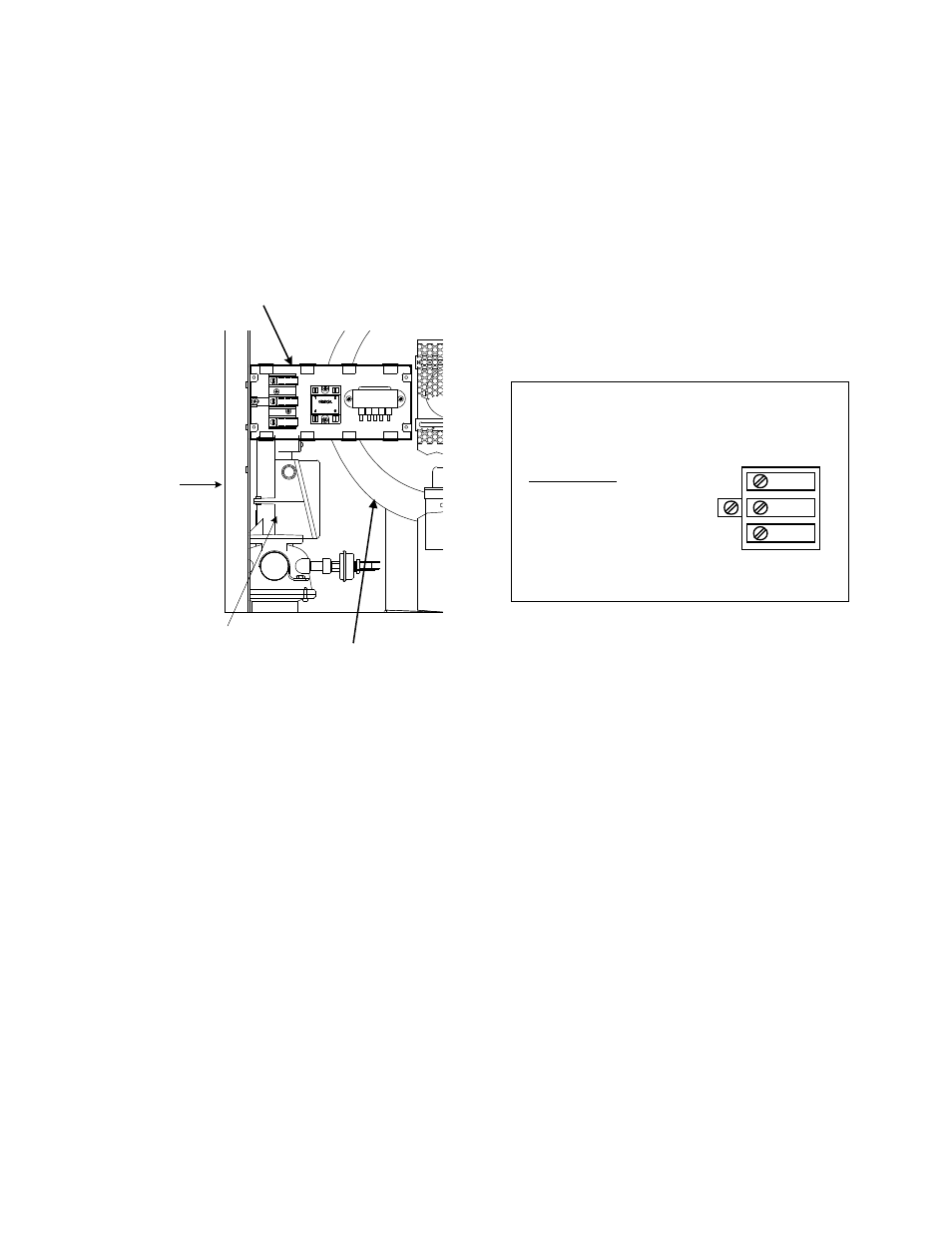

2.5 ELECTRICAL SUPPLY

The AERCO Gas Fired Equipment Electrical

Power Wiring Guide, (GF-1060), must be

consulted in addition to the following material

before wiring to the unit is started. AC power

connection to the unit are made at the Power

Box.This box is located on the front right side of

the unit as shown in Figure 2.7.

POWER BOX

BLOWER

SSOV

ACTUATOR

FRAME

Figure 2.7

AC Power Box Location

NOTE:

All electrical conduit and hardware should

be installed so that it does not interfere with

the removal of any cover, inhibit service or

maintenance, or prevent access between

the unit and walls or another unit.

2.5.1 ELECTRICAL REQUIREMENTS

Electrical requirements for each unit are 120

VAC, 1 Phase, 60 Hz, 20 Amps from a dedicated

electrical circuit. No other devices should be on

the same electrical circuit as a KC1000 unit.

A means for disconnecting AC power from the

unit (such as a service switch) must be installed

near the unit for normal operation and

maintenance. All electrical connections should

be made in accordance with the National

Electrical Code and/or with any applicable local

codes.

The electrical wiring diagram is shown in Figure

2.8. Conduit should be run from the knockouts in

the side of the box in such a manner that it does

not interfere with the removal of any sheet metal

covers. A flexible electrical connection may be

utilized to allow the covers to be easily removed.

USE COPPER CONDUCTORS ONLY FOR FIELD WIRING

60 HZ

DISCONNECT POWER BEFORE SERVICING

DANGER: HIGH VOLTAGE

20 AMP

120 VAC,

NEUTRAL

GROUND

LINE

POWER BOX

AERCO INTERNATIONAL INC.

INPUT POWER

Figure 2.8

AC Power Wiring Diagram

2.6 FIELD CONTROL WIRING

Each unit is fully wired from the factory with an

internal operating control system. No field control

wiring is required for normal operation. However,

the KC1000 control system does allow for some

control and monitoring features. Wiring for these

features can be accomplished in the I/O Box

behind the left side panel (Figures 2.9 and 2.10).

The I/O Box is common to both KC1000 water

heaters and boilers. While some of the inputs

and outputs are common to both water heaters

and boilers, some are not applicable to both.

These are noted in the following paragraphs.

CAUTION!

DO NOT make any connections to the I/O

Box terminals labeled “NOT USED”.

Attempting to do so may cause equipment

damage.