Opener height, Row unit down pressure (spring), Opener height row unit down pressure (spring) – Great Plains V-300F Operator Manual User Manual

Page 95

Great Plains Manufacturing, Inc.

Adjustments

91

11/15/2007

148-057M-A

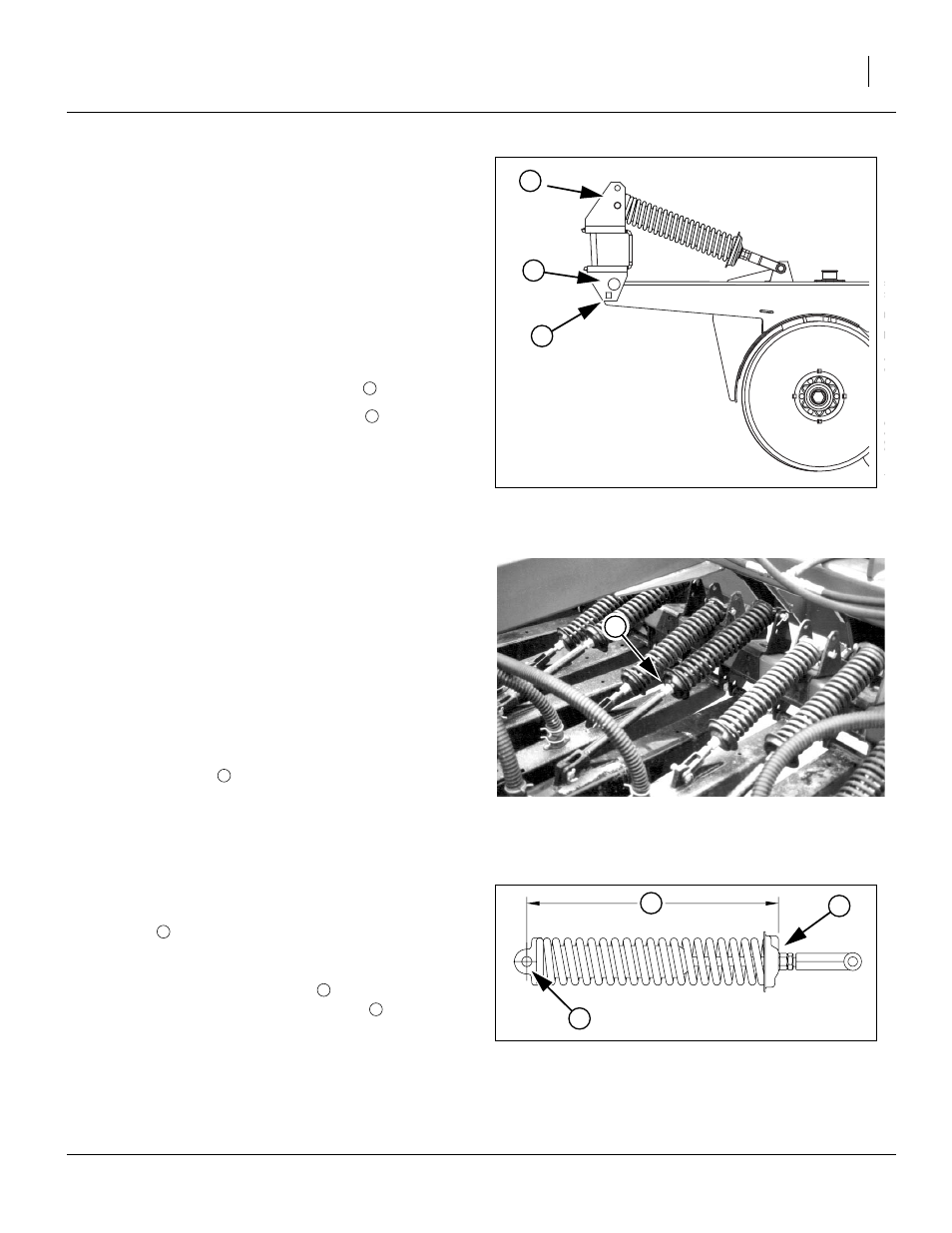

Opener Height

The depth to which the opener disk blades penetrate

the soil is controlled in front by the tool bar and pivot

(opener height), and in the back by the press wheel

height.

If the actual ground level is lower for some rows, such

as those in tire tracks, you can lower that row unit by

lowering the pivot point.

Raise the drill just enough to relieve tension in the

down-pressure spring.

2.

Remove the bolt from the upper hole

3.

Re-position the arm at the lower hole

secure with bolt.

Note: No spring tension or position adjustment is re-

quired. The pivot holes are designed for neutral

effect on spring tension. The bolt at the top end of

the spring uses a hole that depends on spring

length, and not opener height.

Row Unit Down Pressure (Spring)

For planting in tire tracks, and no-till conditions, you can

increase spring pressure on individual or on all openers.

Adjust the spring in conjunction with the sub-frame

down-force, and opener height, to keep the top of the row

unit parallel to the ground.

To set all rows to a higher force, see “Hydraulic Down

Pressure” on page 36.

Refer to Figure 100 and Figure 101

To increase spring pressure:

1.

Loosen jam nut

at lower end of opener spring.

2.

Tighten flange against spring tension.

Note: Each cm adjustment adds about 9 kg of force at

opener disk (approximately 13 pounds per

1

⁄

4

in).

Do not tighten nut more than 2.5 cm (one inch).

3.

After adjusting, lock flange nut in place with jam

nut.

The length

of the spring is factory-set to:

33.8cm (13

5

⁄

16

in).

The reference points for this length are the

center of the upper/front clevis pin

and

the base of the lower/rear spring stop cup

The factory preset length is recommended for conven-

tional till and min-till conditions. Shorten it for rows in

tire tracks or more difficult min-till conditions. The mini-

mum recommended length is:

31.3cm (12

5

⁄

16

in).

Figure 99

Pivot Point Bolt Holes

26382

2

3

1

2

Figure 100

Row Unit Spring Tension

17158

1

Figure 101

00 Series Spring Length

26454

3

2

4

4