Great Plains V-300F Operator Manual User Manual

Page 92

88

V300 & V300F

Great Plains Manufacturing, Inc.

148-057M-A

11/15/2007

5.

Engage the clutch for the fertilizer drive. See

page 86.

6.

If not already done, disengage the clutch for main

seed drive (see page 77).

7.

If not already done, adjust the seed/fertilizer divider

for the intended field operations (see page 33).

8.

Place about 50 liters (20kg, 40 lbs, 2 cu.ft, or 1.5bu)

of material in the fertilizer box.

Rotate the latch

and remove the calibration tray

. Empty and clean it. Re-insert it with the opening

facing up.

10. Make sure the calibration bag is empty and clean.

Hang it from the scale, and adjust the knurled disk

on the top of the scale until the scale reads zero (0).

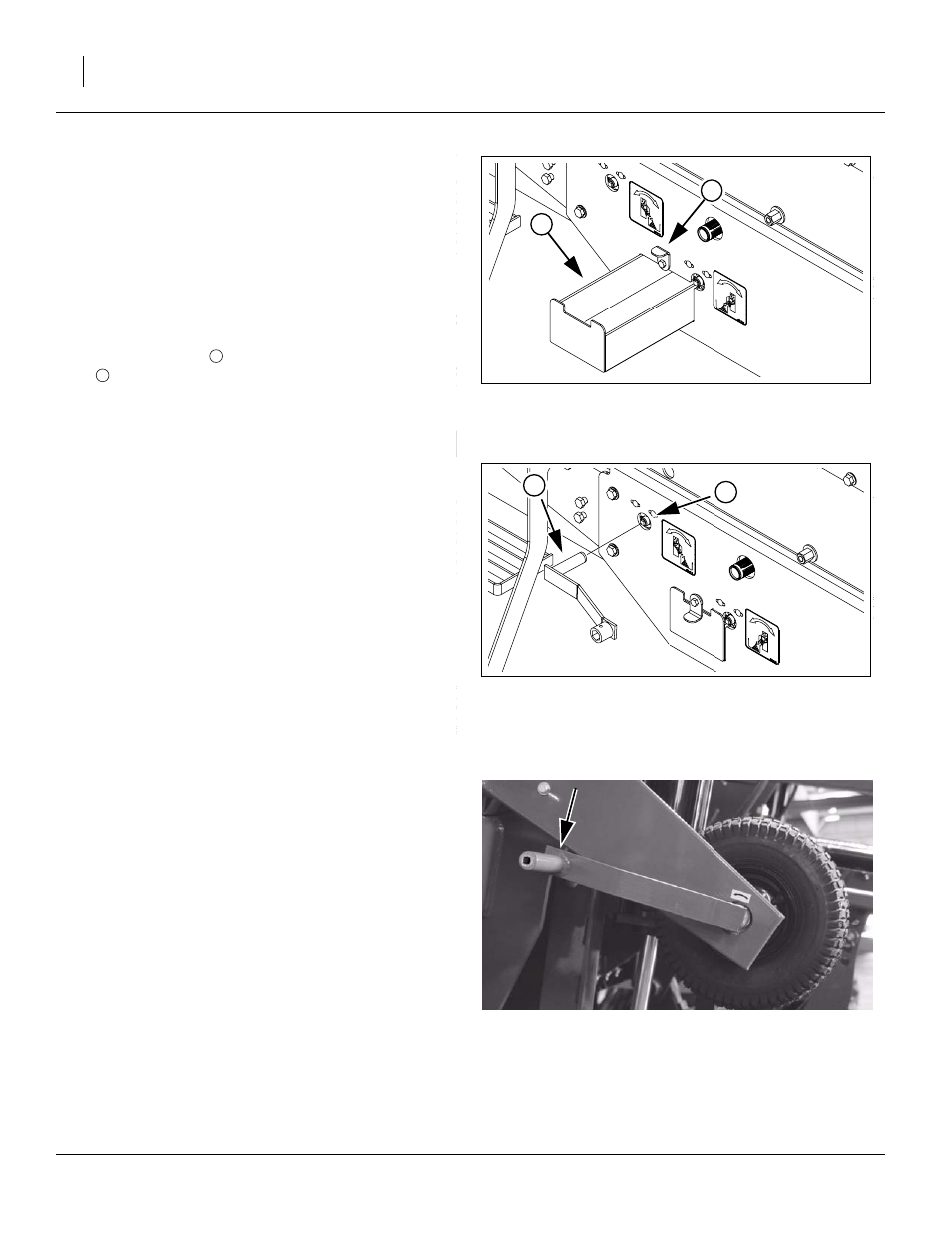

Refer to Figure 96 - The diverter shaft for the fertilizer box is

behind and above the calibration tray.

11. Remove the calibration crank from its storage loca-

tion on the ground drive.

12. Position the square socket of the handle end of the

crank over the calibration shaft index collar for the

fertilizer box. Push in and rotate the shaft counter-

clockwise to set the diverter gates to send material

to the calibration tray.

13. Also use the crank on the seed diverter shaft to close

the gates, so that no seed is mixed with the fertilizer

sample. See page 79.

14. Raise the drill openers and install lift locks.

Refer to Figure 97

15. Position the hex socket end of the calibration crank

on the ground drive contact wheel shaft, and rotate

the shaft counter-clockwise 3 turns. This is to ensure

that the meters are full of material and metering at

the current rate.

16. Remove the calibration tray. Empty it into the main

seed box, and re-insert it (open side up).

17. Rotate crank counter-clockwise. Stop after the first

two turns and check that material is flowing from all

meters. Slowly remove the tray and check for compa-

rable seed piles.

Continue rotating, at an rpm that simulates the

expected application speed (see table on page 74).

Stop periodically. Check that the tray is not over-full.

Stop when the count (from step 4) is reached.

Figure 95

Calibration Tray Removal

27252

2

1

Figure 96

Fertilizer Diverter Shaft

27254

3

4

Figure 97

Calibration Crank Installed

22613