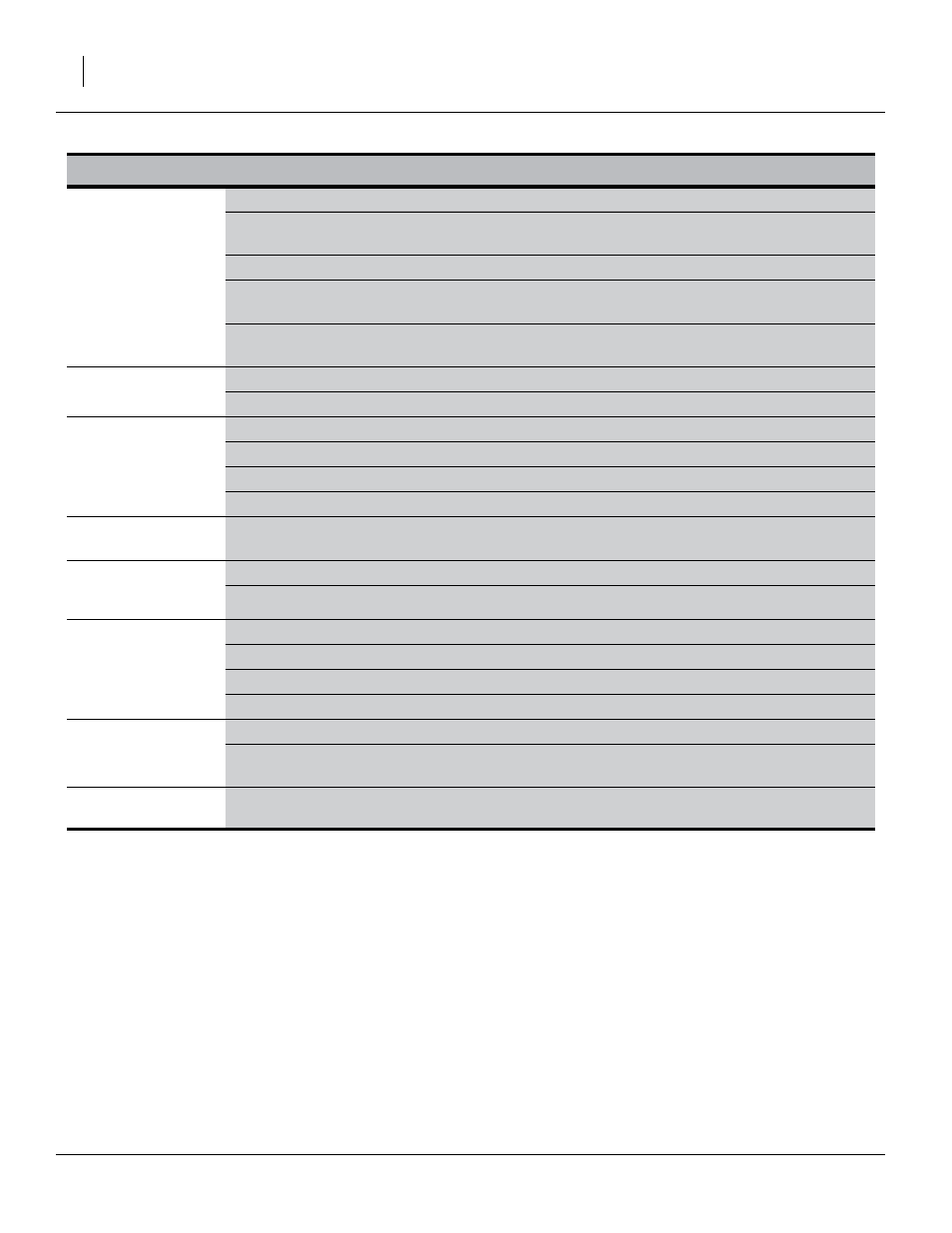

Actual seeding rate is different than desired, Excessive seed cracking, Monitor does not measure accurately – Great Plains V-300F Operator Manual User Manual

Page 100: Uneven seeding depth, Press wheel not compacting soil as desired, Press wheels or openers plugging, Chain-debris/ retainer clip

96

V300 & V300F

Great Plains Manufacturing, Inc.

148-057M-A

11/15/2007

Actual seeding rate

is different than

desired

If not already performed, calibrate.

Check marker extension (page 25). If too short, overlap results in over-seeding. If too long,

gaps result in under-seeding.

Check tire sizes and pressures, listed at “Tire Inflation Chart” on page 114.

Check for build-up of seed treatment in seed cup. Disassemble cups and scrape off any build-

up.

Check seed-rate setting. Seeding rates will vary with seed weight and size. See “Material

Rate Adjustments” starting on page 74.

Excessive seed

cracking

Use a faster drive type and a lower seed-rate-handle setting.

Position seed-cup handles to a lower notch (higher number).

Monitor does not

measure accurately

Check tire sizes and pressures against “Tire Inflation Chart” on page 114.

Check seeding operation for excessive overlap or gaps between passes.

Consider soil conditions–loose soil and slippage will cause variations in acres registered.

Recalilbrate monitor.

Uneven seeding

depth

Check that openers have sufficient down pressure. See “Opener Down-Pressure” on

page 73.

Press wheel not

compacting soil as

desired

Reset press-wheel depth. See “Opener Depth (Press Wheel Height)” on page 93.

Increase down pressure on openers. See “Opener Down-Pressure” on page 73.

Press wheels or

openers plugging

Consider field conditions. Drilling in damp or wet conditions may increase this problem.

Reduce down pressure on openers. See “Opener Down-Pressure” on page 73.

Do not back up or stop and allow drill to roll back with openers in ground.

Check optional Seed-Lok wheels.

Seed-cup sprockets

locked up or twisted

seed-cup shaft

Check for foreign material lodged in seed-cup sprocket.

Look for dried liquid insecticide in seed cups. Remove build-up by disassembling each cup and

scraping turning surfaces.

Chain-Debris/

retainer clip

Be sure retainer clip open end is facing the opposite way of chain travel.

Problem

Solution