Disabling fertilizer box drive, To re-enable fertilizer drive, Fertilizer rate calibration – Great Plains V-300F Operator Manual User Manual

Page 91

Great Plains Manufacturing, Inc.

Adjustments

87

11/15/2007

148-057M-A

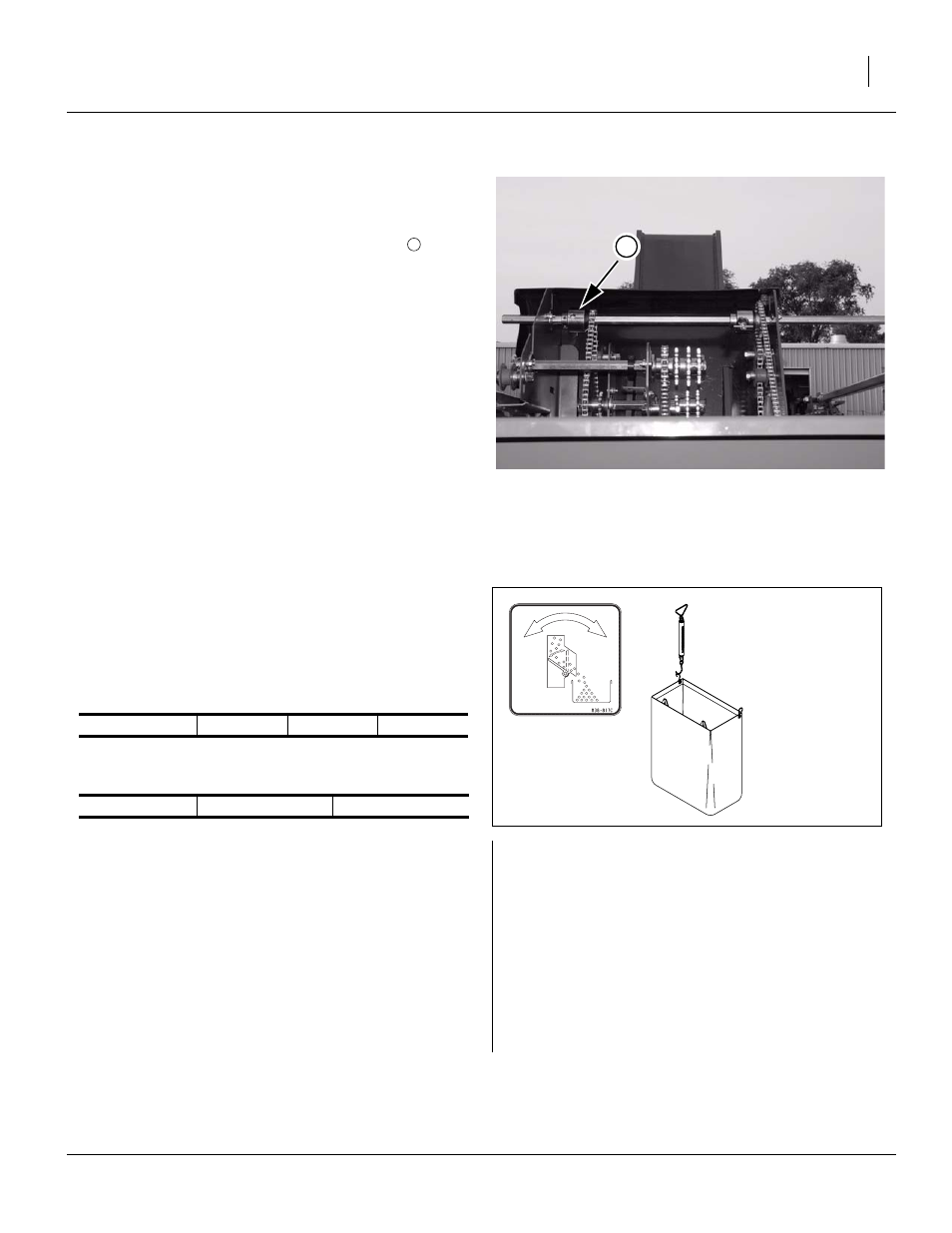

Disabling Fertilizer Box Drive

To prevent wear when applying only seed, and when cal-

ibrating main seed, the fertilizer shaft can be disengaged

from the drive system.

The drive is engaged when the clutch cross pin

seats

in the deeper detent, pin perpendicular to the shaft.

Refer to Figure 94, a rear view of the shaft with the seed boxes

removed, and Figure 85, an exploded view from above left rear

1.

It may be necessary to remove one or both guards to

gain access to the clutch.

2.

Pull the cross pin away from the shaft. Rotate

1

⁄

4

turn. Seat in shallower detent parallel to the shaft.

To re-enable fertilizer drive:

3.

Pull the cross pin away from the shaft, and rotate it

1

⁄

4

turn, seating it in the deeper detent perpendicular

to the shaft.

Note: The pin does not need to fully seat at this time. It

automatically drops into full engagement at the

next movement of the ground drive.

4.

Re-mount any removed guards.

Fertilizer Rate Calibration

Calibration is strongly recommended. Fertilizer density

and can granularity can be substantially different from

the material used to generate the charts.

The V300F has a diverter on each fertilizer meter, which

send metered material to a calibration tray:

The V300F includes a calibration bag for weighing sam-

ples, and a spring scale:

The spring scale requires a sample of at least 2.5 kg or

5 lbs for useful precision. Typically, this requires simulat-

ing at least

1

⁄

10

hectare or acre. If you have a scale accu-

rate at lower weights, you can use a smaller sample size.

These instructions presume a calibration using the sup-

plied accessories.

Refer to sample data and formulas at right.

1.

Correct for density, if that step was completed.

2.

Consult the fertilizer rate chart in the Seed Rate

Manual.

3.

Set the Range, Driving and Driven sprockets.

4.

Using the rate chart, and the crank revolutions table

on page 74, determine how many crank revolutions

are required to generate a measurable sample size.

Tray Capacity

37.3 liters

1.06 bu.

1.32 cu.ft.

Scale Capacity

2.5-to-25 kg

5-to-50 pounds

Figure 94

Fertilizer Drive Clutch

22611

1

Example:

Desired Application Rate: 128 kg per hectare

Expected planting speed: 7 kph

Density-corrected rate: 182 kg/Ha

Range: High (16T)

Driving sprocket: 17T

Driven sprocket: 20T

Expected sample size for

1

⁄

10

hectare: 12.8 kg

Crank revolutions for

1

⁄

10

hectare: 320

Recommended crank rpm: 112