Maintenance and lubrication, Maintenance, Bleeding hydraulic systems – Great Plains V-300F Operator Manual User Manual

Page 101: Maintenance and lubrication maintenance, Warning

11/15/2007

148-057M-A

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

97

Maintenance and Lubrication

Maintenance

Proper servicing and adjustment are key to long life of

any farm implement. With careful and systematic inspec-

tion, you can avoid costly maintenance, time and repair.

Always turn off and remove tractor key before making

any adjustments or performing any maintenance.

!

WARNING

You may be severely injured or killed by being crushed by the

falling implement. Always have transport locks in place and

frame sufficiently blocked up when working on implement.

!

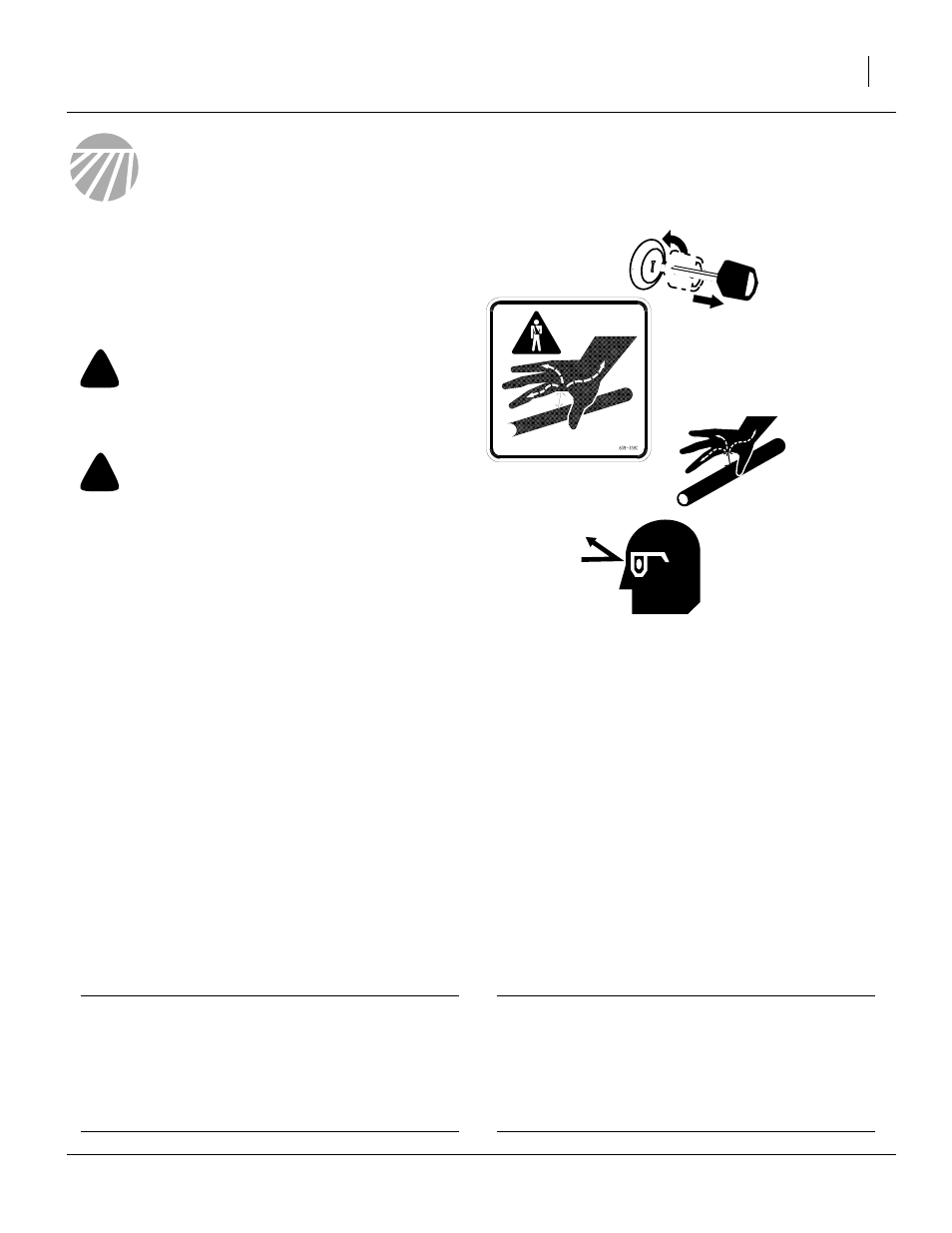

WARNING

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Check all hydraulic lines and fittings before

applying pressure. Fluid escaping from a very small hole can

be almost invisible. Use paper or cardboard, not body parts,

and wear heavy gloves to check for suspected leaks. If injured,

seek medical assistance from a doctor that is familiar with this

type of injury. Foreign fluids in the tissue must be surgically

removed within a few hours or gangrene will result.

Only trained personnel should work on system hydraulics!

1.

After using implement for several hours, check all

bolts to be sure they are tight.

2.

Inflate tires as specified under “Tire Inflation Chart”

on page 114.

3.

Replace any worn, damaged or illegible safety

decals. Obtain new decals from your Great Plains

dealer. See “Safety Decals and Reflectors” on

page 6 for decal placement.

4.

Check drill drive chains for wear. Replace if neces-

sary. Adjust idlers to remove excess slack from chains.

Bleeding Hydraulic Systems

For safe and smooth operation, the hydraulic systems

must be free of air. The hydraulic systems should be bled

during initial implement set-up. If not, or if you repair

replace a hydraulic component, bleed the hydraulics.

IMPORTANT !

Bleed only at:

JIC (Joint Industry Conference, 37

°

flare) or

NPT (National Pipe Thread, tapered thread) fittings.

Never bleed at:

ORB (O-Ring Boss) or

QD (Quick Disconnect) fittings.

OFF

IMPORTANT !

JIC fittings do not require high torque. JIC and O-ring

fittings do not require sealant. Always use liquid pipe

sealant when adding or replacing (NPT) pipe-thread

fittings. To avoid cracking hydraulic fittings from over

tightening, and to keep tape fragments from clogging

filters, do not use plastic sealant tape.