Packer setup – Great Plains V-300F Operator Manual User Manual

Page 32

28

V300 & V300F

Great Plains Manufacturing, Inc.

148-057M-A

11/15/2007

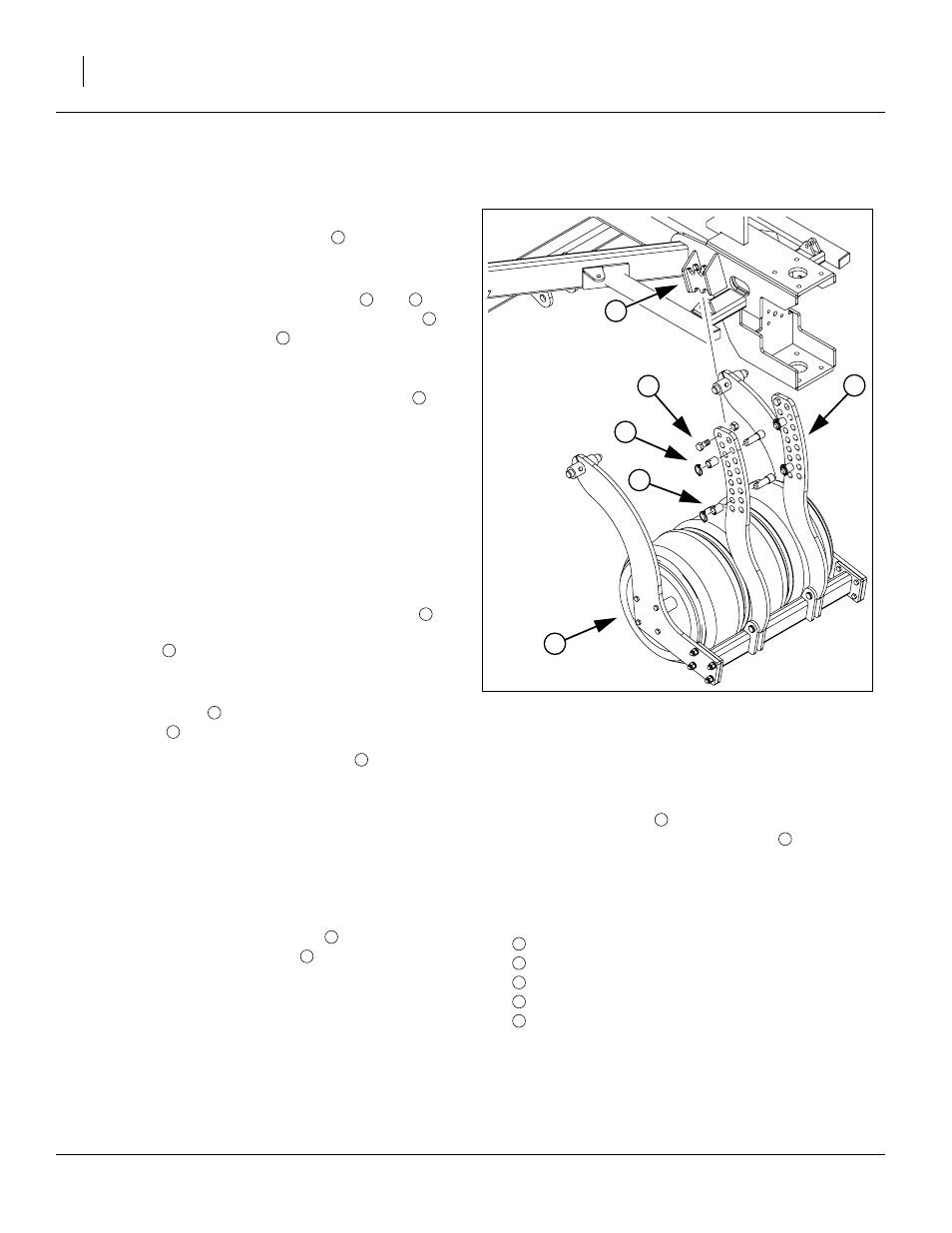

Packer Setup

Refer to Figure 28

The optional packer arm kit as supplied by Great Plains

does not include the packer assembly

tires). Your dealer can install the packer arms only if the

packer assembly is also available during installation.

The packer arms have movable stop pins (

which limit the travel of the packer adjustment arms

in

the adjustment arm weldment

depends in part on your field conditions and tillage prac-

tices.

Note: Should the pins fall out or be lost, limit bolts

are

also present in the topmost arm hole, to prevent the

packer from striking the ground when the drill is

raised. Do not remove bolts. Replace lost pins.

Before setting up the packer, decide if you intend to let

the packers rely strictly on their own weight, or carry

some of the weight of the drill.

To adjust the packer, hitch the drill and, if not already

completed, perform the leveling (page 19). Leave any

extra weights or seed load present. Move the drill to level

ground similar to expected field conditions.

1.

Lower the drill and remove the upper stop pins

Raise the drill, install lift locks, and remove the lower

stop pins

.

2.

Lower the drill until the presswheels just contact the

ground. Note the lowest fully exposed hole in the

adjustment arm

just above the adjustment arm

weldment

.

3.

Lower the drill and insert the top pins

in the next

lower hole on each side.

Note: The packer wheel now raises to the same clear-

ance as the press wheels. If the packer is not fol-

lowing into deeper field depressions, the pins can

be moved up to increase the downward range. Do

not set the pins so high that the packer can strike

the ground during transport.

4.

If you intend to have the packers rely only on their

own weight, insert the lower pins

in the lowest

holes of the adjustment arms

. Skip the remaining

steps below.

If you intend to have the packers carry some drill weight,

continue with step 5.

5.

Lower the drill and pull forward 3 meters or so.

Check that the hitch is level, and that coulter depth

and opener depth are as intended.

6.

Insert the lower pins

in the highest available holes

just beneath the adjustment weldment

7.

Raise the drill, and move the pins up by:

one hole increment to transfer a small weight, or

two hole increments to transfer significant weight.

8.

Lower the drill, pull forward, and check:

packers not excessively compressed

hitch level

coulters at correct depth

openers at correct depth

gauge wheels have adequate traction

Figure 28

Packer Stops

27260

1

3

2

6

5

4

1

2

3

5

2

5