Marker maintenance, Bleeding marker hydraulics, Caution – Great Plains V-300F Operator Manual User Manual

Page 105

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

101

11/15/2007

148-057M-A

Marker Maintenance

See also:

“Marker Setup” on page 25,

“Marker Operation” on page 40

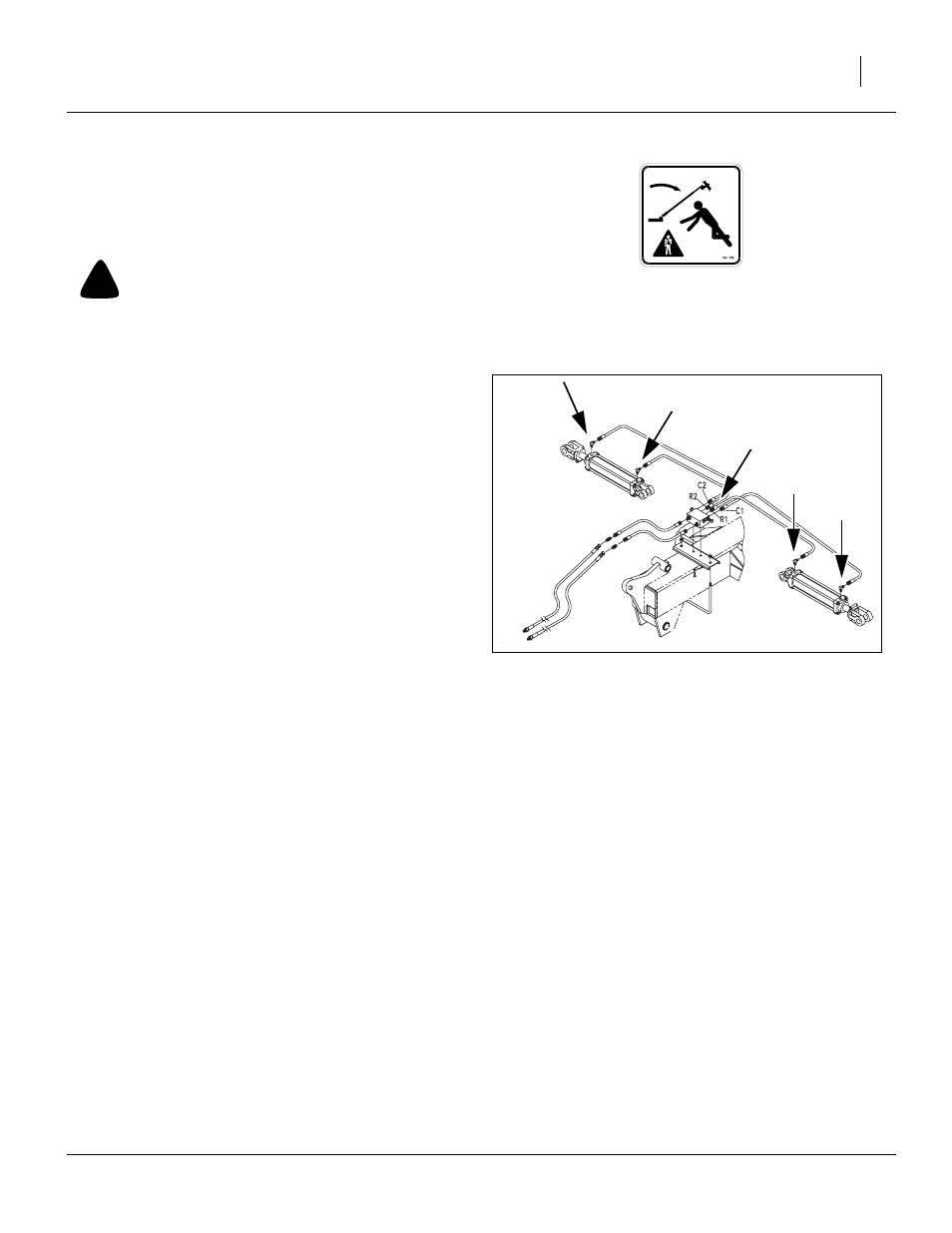

Bleeding Marker Hydraulics

!

CAUTION

You may be injured if hit by a folding or unfolding marker.

Markers may fall quickly and unexpectedly if the hydraulics

fail. Never allow anyone near the drill when folding or unfold-

ing the markers.

1.

Check that tractor hydraulic reservoir is full.

Extend a marker.

3.

Loosen hydraulic-hose JIC fittings at rod and base

ends of the marker cylinder.

4.

Loosen fittings on back side of sequence valve for

that side.

5.

With tractor idling, activate tractor hydraulic valve to

extend marker, until oil seeps out around a loosened

fitting. Tighten that fitting.

6.

Re-activate (for extend) until oil seeps at another fit-

ting. Tighten it.

Note: The markers are controlled by an automatic se-

quence valve, which can complicate bleeding. If the

marker on the other side begins moving before you

intend it, momentarily reverse the lever for the cir-

cuit.

7.

Reverse the tractor hydraulic valve (to retract) until

oil seeps out around the loosened fitting on the other

end of the cylinder or sequence valve port. Tighten

that fitting.

8.

Re-activate (for retract) until there is seepage at the

final loose fitting on that side. Tighten the fitting.

9.

Fully retract the marker on that side.

10. Repeat step 2 through step 9 for the other side.

Figure 113

Marker Cylinder Bleed

17873