Hydraulic drive maintenance, To change the element – Great Plains YP1625 Operator Manual User Manual

Page 87

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

83

03/12/2012

401-226M-A

Hydraulic Drive Maintenance

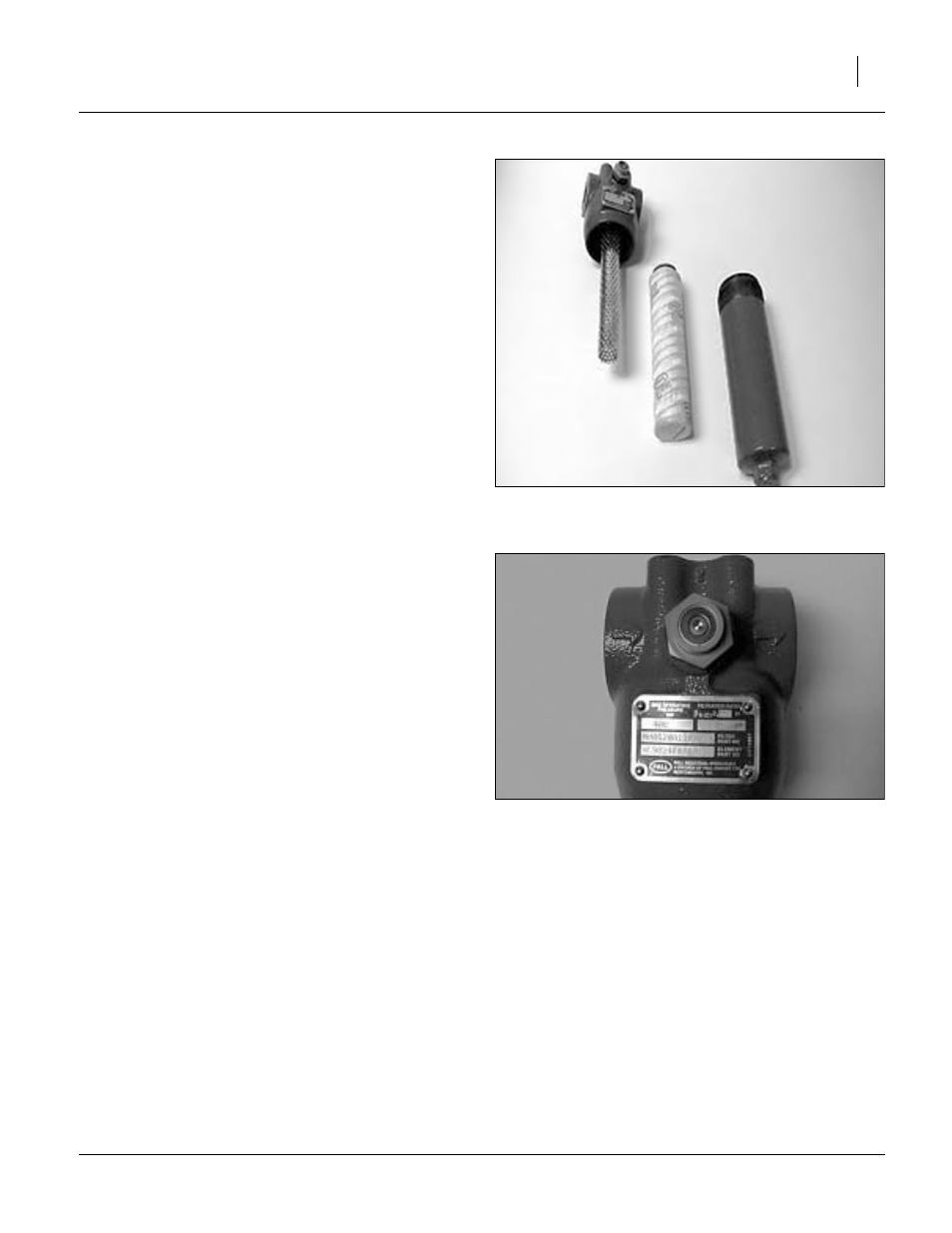

As with any hydraulic system, contamination is the most

common cause of performance problems and pre-

mature wear. Make a special effort to properly clean

quick couplers prior to attaching the hoses to tractor.

Filter: All fluid is filtered through the high pressure filter

(p/n 18574) and it provides protection to the hydraulic

components of your drive if properly maintained. It is

equipped with a pop-out indicator to alert that the

replaceable element is clogged, and should be changed

immediately if this situation occurs. Normal service life of

the element will vary based on the precautions that you

take to minimize contamination at the couplers and rou-

tine service of the tractor filtration.

To change the element:

Refer to Figure 119

1.

Un-screw lower canister from filter, catching and dis-

posing of used fluid.

2.

Remove and discard element.

3.

Install new element (p/n 19856)

4.

Clean canister threads and lube o-ring with hydraulic

fluid, then re-install.

Refer to Figure 120

5.

Re-set pop-out indicator if necessary.

It is a good idea to keep a filter element on hand, and we

recommend changing at a minimum on an annual basis.

6.

Between planting seasons, store cab console inside

in a relatively stable and dry environment.

7.

Avoid direct spray from high pressure washers on

the motor encoder and the external controller box.

These units are sealed from normal moisture, but

high pressure could inject water into the housing.

8.

Keep electrical connects free from dirt and grease.

It’s a good idea to occasionally spray the terminals

with contact cleaner to ensure proper connection.

FigureSpacer:

Figure 119

Hydraulic Filter

22736

FigureSpacer:

Figure 120

Hydraulic Filter Indicator

22737