Field setup checklist – Great Plains YP1625 Operator Manual User Manual

Page 40

36

YP1225 and YP1625

Great Plains Manufacturing, Inc.

401-226M-A

03/12/2012

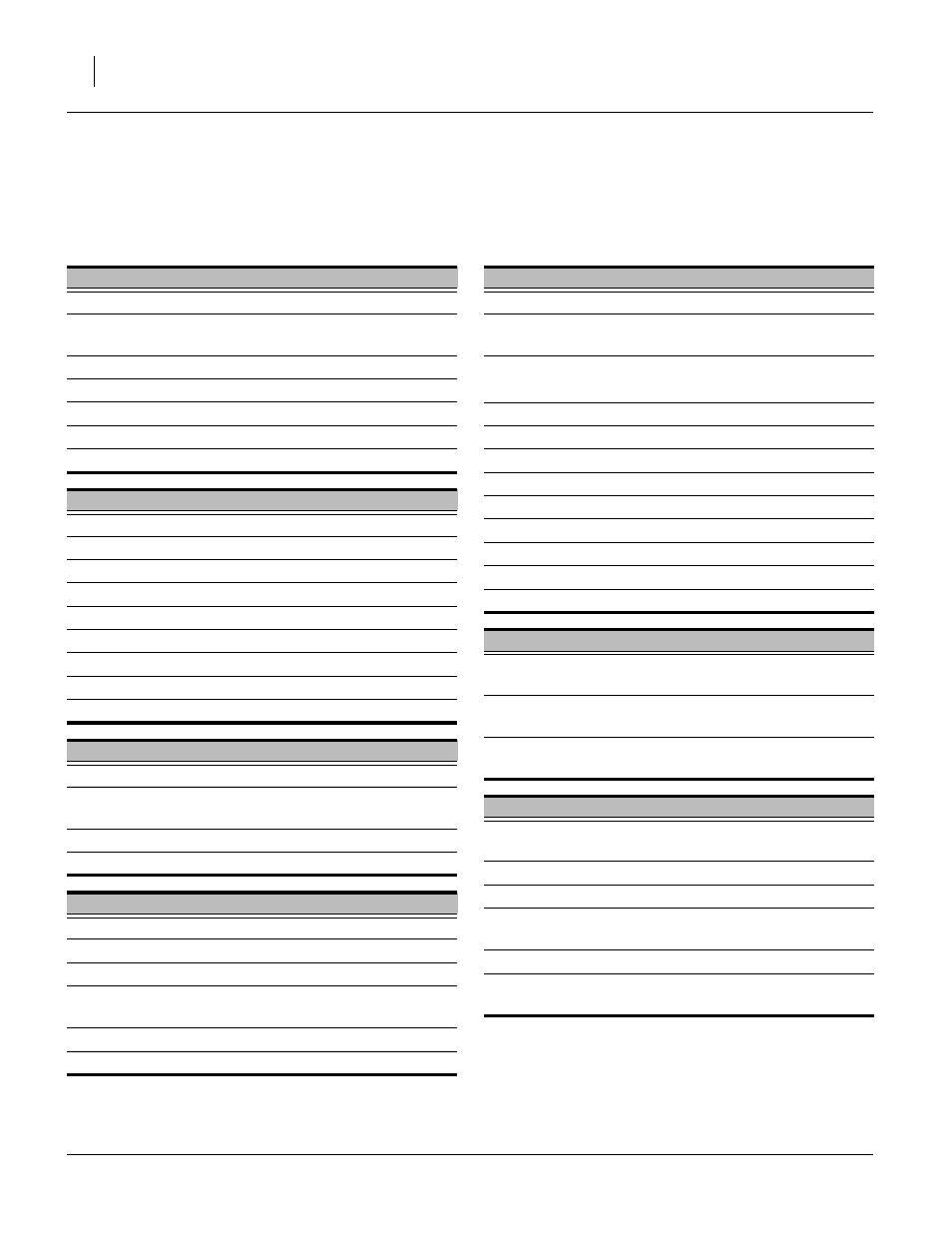

Field Setup Checklist

Use the following checklist as a guide to ensure the

planter is properly set up before using. You may need to

refer to the assembly instructions, operator’s manual or

the Dickey-john manual to complete checklist.

FigureSpacer:

FigureSpacer:

FigureSpacer:

FigureSpacer:

FigureSpacer:

FigureSpacer:

FigureSpacer:

MECHANICAL

❑ Tongue height preset on 3-point.

❑ Set tractor 3-point hitch to “depth control” operation

(and not load control)

❑ Front to rear levelness.

❑ Side to side levelness at gauge wheels.

❑ Toe-in of wing frames at pull-bars.

❑ Tongue hook latch operation.

❑ Marker extension and disk angle set.

HYDRAULIC

❑ All circuits connected with correct polarity.

❑ Tractor reservoir full.

❑ Field raise and lower.

❑ Inspect for leaks.

❑ Fold/unfold and tongue lock.

❑ Markers.

❑ Solenoid valve.

❑ Fan direction and speed.

❑ Hydraulic drive (if equipped).

ELECTRICAL

❑ Power up monitor and check settings.

❑ Power up and check hydraulic settings if not already

done.

❑ Check operation of selector valve for fold/makers.

❑ Check operation of lighting equipment.

AIR SYSTEM

❑ Manifold to PROBOX or poly hopper seal.

❑ Y-splitters turned on to correct rows.

❑ Air leaks (small leaks from PROBOX are normal.

❑ Hose routings, no sags and no pinched hoses.

(Check both folded and field positions.)

❑ Cleanout doors closed at meters.

❑ Hoses fully connected to meters and locked.

ROW UNITS

❑ Preset depth handles to 7 holes showing above “T”

❑ Preset down force springs to 1st notch (lightest) set-

ting for most conditions, 2nd notch otherwise.

❑ Set all unit mounted coulters to

1

⁄

4

in (6mm) above

opener blade depth.

❑ Check coulter alignment to row.

❑ Check closing wheel alignment.

❑ Set closing wheels to first notch (light setting).

❑ Correct seed meters and wheels installed.

❑ Meter drive coupler engaged for all desired rows.

❑ Seed meter clean-out doors closed.

❑ Check scraper gaps (option).

❑ Lock up splitter rows if needed.

❑ Check action and contact of side depth wheels.

ROW CLEANERS

❑ Check for correct installation of row cleaners on all

rows if equipped.

❑ Check that row cleaners do not catch on hydraulic

hoses.

❑ Carefully watch when folding planter the first time to

ensure clearance of row cleaner.

FERTILIZER

❑ Set rate drive sprockets for correct rate.

(Note fertilizer rate is population dependent.)

❑ Check for correct orifice plates.

❑ Check unused rows are correctly closed off.

❑ Fill system 1/2 full with water and check for leaks

(run pump if possible).

❑ Disconnect drive chain if fertilizer is not used.

❑ Check all row unit lines are connected and dis-

charge nozzles or tubes are clear.