Press wheel adjustments, Press wheel centering, 98 7 c – Great Plains YP1625 Operator Manual User Manual

Page 75

Great Plains Manufacturing, Inc.

Adjustments

71

03/12/2012

401-226M-A

Press Wheel Adjustments

Attached to the rear of each row-unit is one of several

press wheel options.

To provide consistent seed firming, the press wheels are

free to move downward from their normal operating posi-

tion. This system maintains pressing action even if the

row-unit arm is lifted when the disks encounter obstruc-

tions.

Refer to Figure 106

Press wheels are attached to each row-unit body. The

press wheels close the seed trench and gently press soil

over seed.

An adjustable spring in the press wheel mechanism cre-

ates the down pressure needed to close the seed trench.

The amount of force needed will vary with field condi-

tions.

To adjust, move adjustment handle.

• For less down pressure, move handle forward toward

planter.

• For more down pressure, move handle back away

from planter.

Note: Increased press wheel spring force may require in-

creased row-unit down force to maintain depth.

Note: The factory setting on the press wheel is staggered

to achieve optimum residue flow.

Refer to Figure 107

To adjust press wheels from staggered to even, remove

5

⁄

8

in bolt

, and lock washer

press wheel

and hardware to the other hole location.

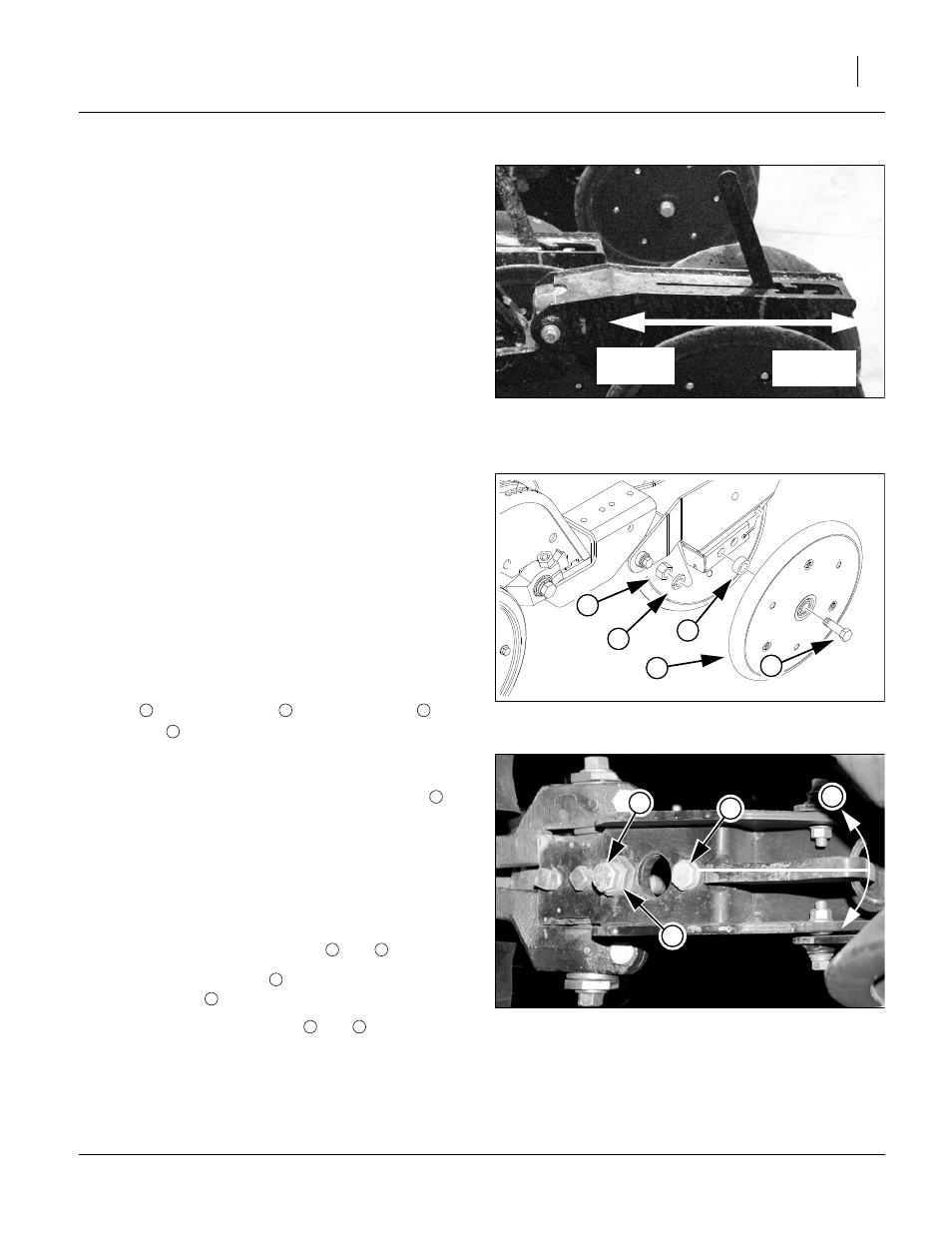

Press Wheel Centering

If one press wheel is running in the seed trench, or the

wheels are not centered over the trench, the angle

of

the press wheel assembly can be adjusted as follows:

Refer to Figure 108

1.

Determine how far, and in which direction, the press

wheel assembly needs to move to center the wheels.

2.

Raise planter and install lift assist cylinder locks. See

“Important Safety Information” on page 1.

3.

Loosen the

1

⁄

2

in hex-head bolts

and

.

4.

Turn the hex head cam

under the forward hex

head jam bolt

, and move the required amount.

5.

Tighten both hex-head bolts

and

.

If press wheel adjustments do not provide satisfactory

furrow closing, your conditions may require alternate

press wheels. A variety of wheel assemblies are avail-

able. Consult your Great Plains dealer.

FigureSpacer:

Figure 106

Press Wheel Adjustment

21948

FigureSpacer:

More Down

Pressure

FigureSpacer:

Less Down

Pressure

FigureSpacer:

Figure 107

Press Wheel Stagger

22907

2

3

4

1

5

3

4

FigureSpacer:

Note: Do not loosen the square-head bolts forward of the

hex-head bolts.

Figure 108

Press Wheel Centering

(View from beneath opener)

25277

9

8

7

c

7

8

9

c

9

8

9