Troubleshooting – Great Plains YP1625 Operator Manual User Manual

Page 76

401-226M-A

03/12/2012

72

YP1225 and YP1625

Great Plains Manufacturing, Inc.

Troubleshooting

Note: For seed monitor issues, see also the DICKEY-john

Planter/Drill Control Operator’s Manual,

“TROUBLESHOOTING & ALARMS” section..

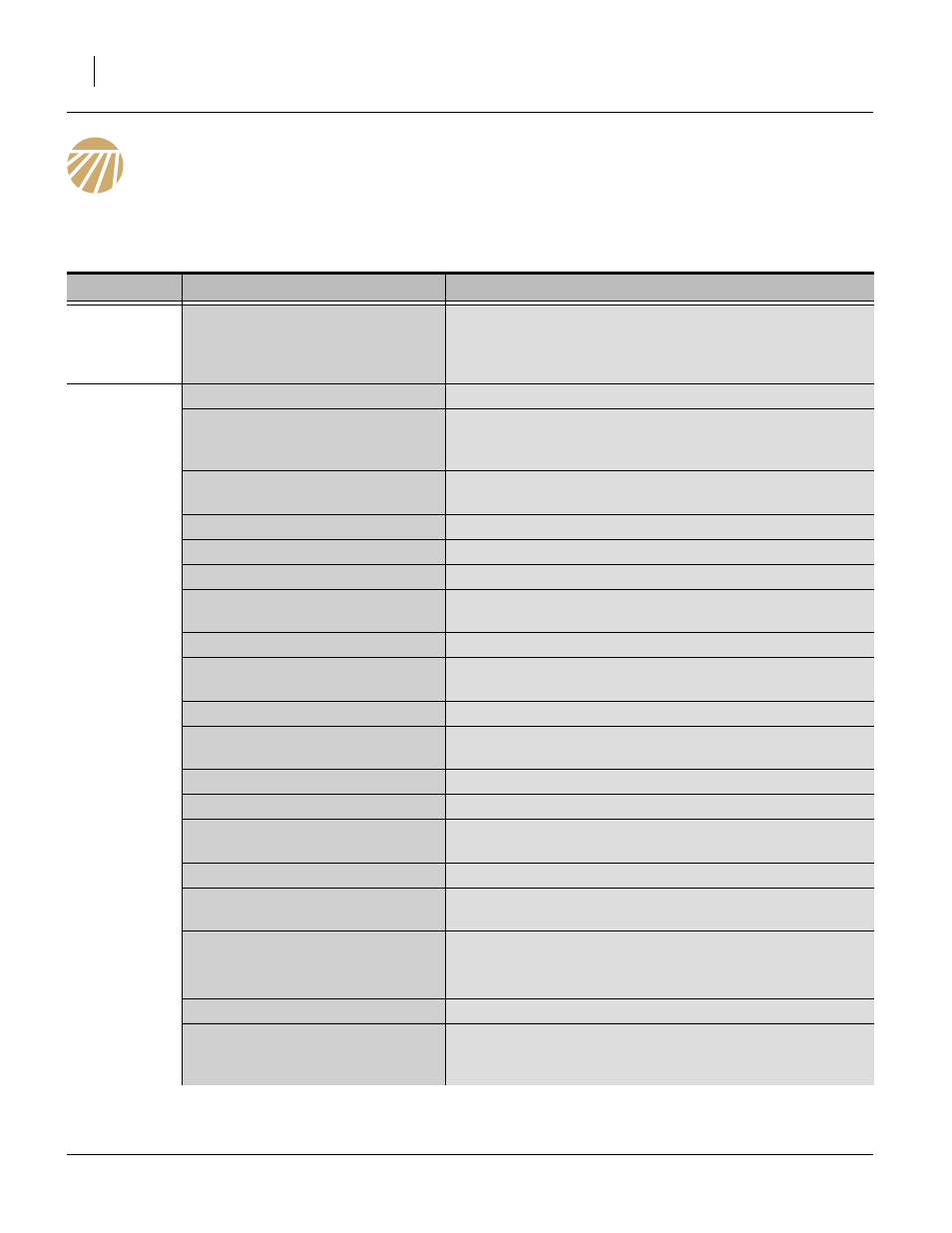

Problem

Cause

Solution

Population

Alarms

False alarms or actual seed rate

errors due to monitor setup with

incorrect row count, spacing or

active rows

Review planter configuration and monitor setup.

Planting too

little

Incorrect seed rate.

Check seed rate information and planter rate setup.

Incorrect seed wheel cell count or

finger count.

Use chart rates for installed components, or replace wheels

or finger meters. Charts are based on either 6 finger or 12

finger meters or various wheel counts.

Incorrect seed wheel cell size can

cause skips

Install meter wheels with cell sizes recommended for seed

size.

Brush too tight on finger meter

Adjust brush (page 68).

Low contact drive tire pressure

Inflate all tires to recommended levels (page 111).

Meter drive not engaged

Engage drive coupler (page 67)

Incorrect fan airflow

Adjust fan speed to recommended rpm (page 39).

Employ baffle in unusual situations (page 50).

Excessive field speed.

Reduce field speed.

Incorrect tire size or air pressure.

Use correct chart for tire brand and model (see Seed Rate

manual). Use correct air pressure, page 111.

Actual field size is different.

Verify field size.

Excessive gaps between planter

passes.

Adjust marker, page 49.

Plugged row-unit seed tube.

Lift planter, expose bottom of seed tube and clean out.

Thrown or worn drive chains

Check drive chains.

Worn sprockets, chain idlers or

meter components.

Replace worn items.

Loose assemblies in finger meters

Have dealer service meters.

Improper main shaft sprocket.

Check sprockets. Hydraulic drive uses 23-tooth. Ground

drive uses 25-tooth.

Improper gap on speed sensor.

Check speed sensor on planter for

1

⁄

16

in to

1

⁄

8

in (1.6-3.2mm)

gap from wheel. Improper gap can cause erratic speed sig-

nal causing monitor to falsely report improper planting rate.

Incorrect speed sensor constant

Perform speed calibration per DICKEY-john monitor manual.

Rate may not actually be low

When planting volumetric seeds, the monitor functions as a

blockage detector, and does not count all seeds.