Electric clutch operation, Electric clutch lockup – Great Plains YP1625 Operator Manual User Manual

Page 44

40

YP1225 and YP1625

Great Plains Manufacturing, Inc.

401-226M-A

03/12/2012

Electric Clutch Operation

Refer to Figure 49, which depicts the left planter side on and

the right side shut off.

Electric clutches allow for turning planting off while the

planter is lowered. A clutch for each drive shaft allows for

independent control of each side of the planter. The

clutches are controlled via the CFM “CLUTCH” switches.

For regular field operation, turn “MASTER”

and “Right”

clutch switches to the “ON” position. This

activates the magnet on each clutch and allow clutch

shafts to rotate.

To shut off planting on one or both sides to accommo-

date point row while planter is lowered, switch either to

“OFF” position. Turning the MASTER switch off disen-

gages both sides. If the planter has hydraulic meter

drive, MASTER off also shuts down the drive motor.

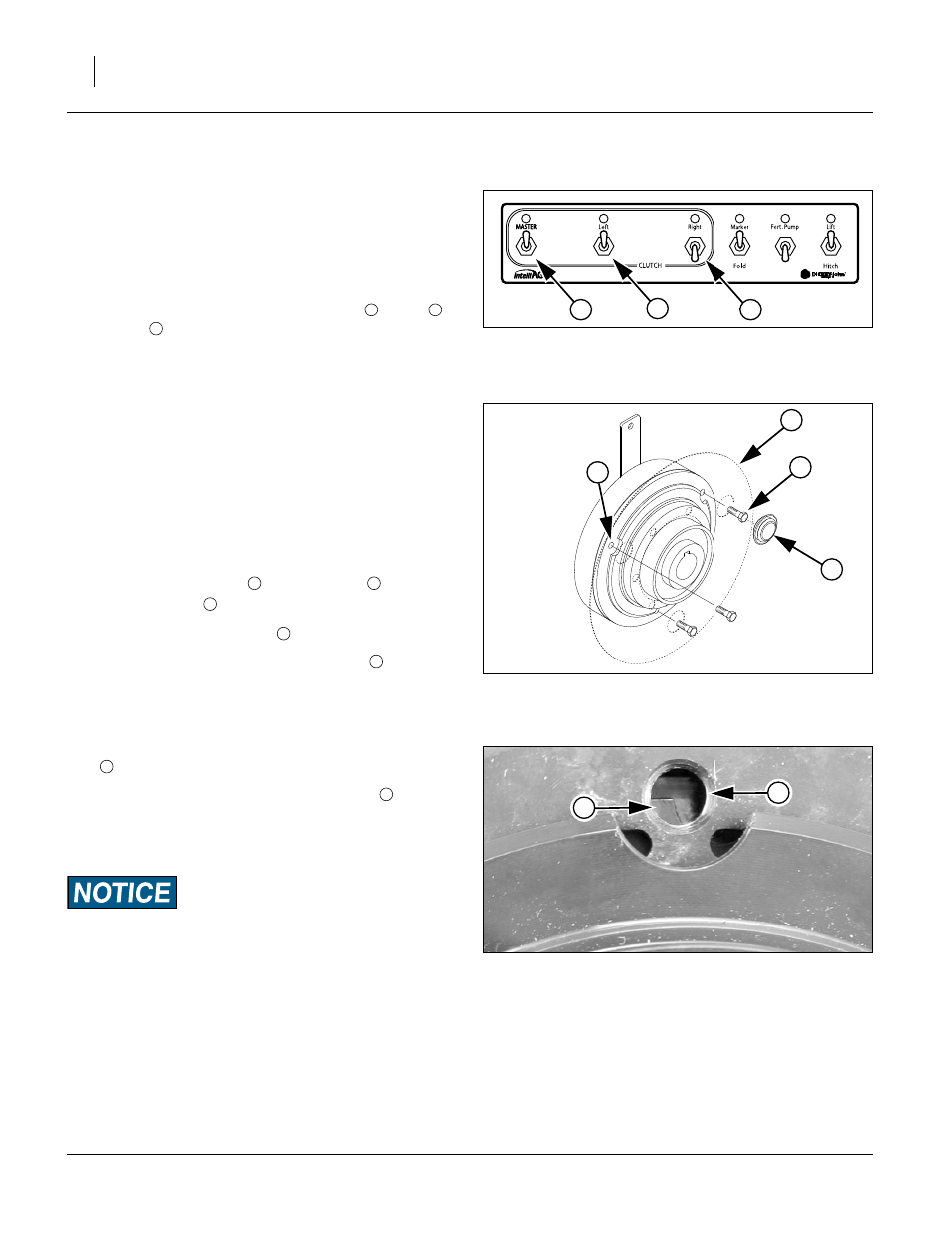

Electric Clutch Lockup

Refer to Figure 50

In case of electric clutch failure, electric clutches can be

bolted together.

1.

Remove rubber plugs

access to bolts

.

2.

Align cutouts at bolt holes

.

3.

Insert M8-1.25x14mm long metric bolts

.

Note: Use only 14mm length bolts as provided or ma-

chine damage will occur. Longer bolts will damage

the clutch. Shorter bolts may not effect a lock-up.

If you observe half the hole obstructed by a metal

disc

, you are not at a cutout.

If the entire hole is obstructed by a metal disc

, you are

not at a cutout.

When at a cutout, the bolt will screw in with minimal

resistance until the bolt head reaches the clutch face.

Clutch Slippage Risk:

When lubricating the planter, do not allow lubricant to enter

the clutch, or clutch slippage will result.

FigureSpacer:

FigureSpacer:

Figure 49

CFM: Point Row

28490

1

2

3

1

2

FigureSpacer:

Figure 50

Electric Clutch Lockup

29329

4

3

2

1

2

3

4

3

FigureSpacer:

Figure 51

Clutch Plate Nearly at Cutout

26168

5

4

5

5