Transmig 250i problems/service – Tweco 250i Transmig Inverter User Manual

Page 80

TRANSMIG 250i

PROBLEMS/SERVICE

PROBLEMS AND ROUTINE SERVICE

5-2

Manual 0-5187

23

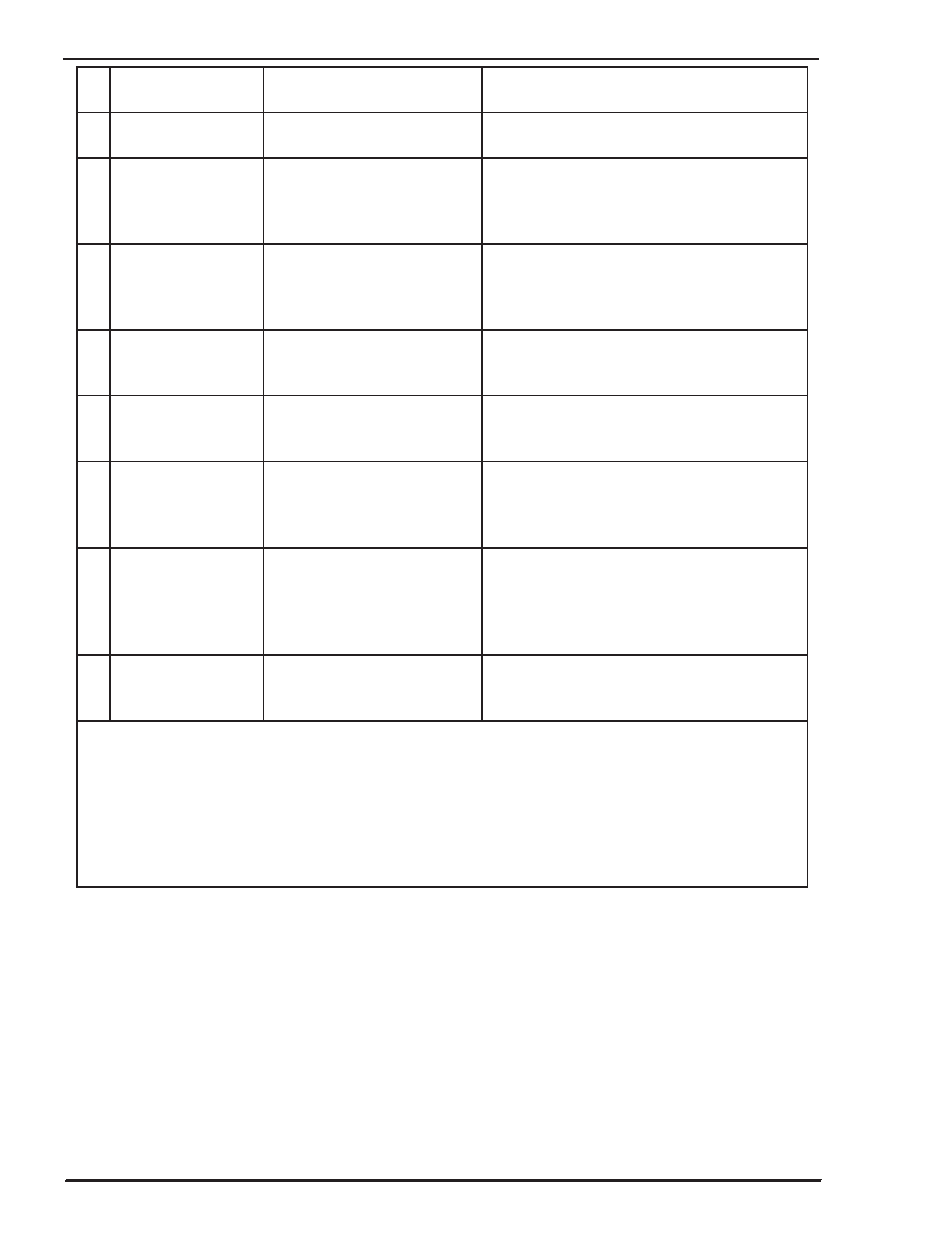

Weld Fault

Welder detected a fault during

the weld process

Consult an Accredited CIGWELD Service

Provider if symptom recurs frequently.

24 Code Memory Fault Welder detected a fault in

program flash memory

Firmware image is corrupted. Consult an

Accredited CIGWELD Service Provider.

25 Nonvolatile Memory

Fault

Welder detected a fault in

parameter NVROM.

A. Welding may still be possible, but no weld

setting changes can be saved.

B. Consult an Accredited CIGWELD Service

Provider.

26 Unknown PCB Fault Welder control board cannot

identify an attached inverter

board and/or determine its

own identity

Consult an Accredited CIGWELD Service

Provider.

30 Service Mode Switch

Fault

SERVICE DIP switch is

enabled

Welding is disabled while SERVICE Mode DIP

switch is enabled. Disable SERVICE Mode

switch to resume welding.

31

Controller Fault

Welder control board has

detected a hardware fault on

itself

Consult an Accredited CIGWELD Service

Provider if symptom recurs frequently.

33

Calibration Fault

An output (current, voltage,

or motor) fault was detected

while attempting a calibration

process

A. Check integrity of welder cables, MIG Torch

or electrode holder and retry calibration.

B. Check MIG wire spool, feedplate area for

wire feed issues, correct and retry calibration

34

User Calibration

Abort

User-initiated abort/

interruption of an active

calibration process occurred

(usually, release of trigger too

early)

Restart/reselect calibration process and retry

calibration when ready.

35

Parameter Fault

Welder control board has

detected a parameter out of

range

System Parameter re-initialization has been

automatically performed or is required

(Factory Default Reset)

Note 1: If the left display is alternate flashing "Err" and "Code" this is indicating that the fault was detected

but has either stopped occurring or is in the process of clearing itself. If this is the case, the flashing error

message will return to normal display functionality within 10 seconds unless another fault occurs. If the

left display shows a steady "Err" this is indicating that the fault is persistent and is still being detected.

Note 2: Flashing Amperage and Voltage displays (when welding) indicates that the machines maximum

output power rating (300A x 26.7V = 8kVA) is being exceeded and the system is automatically reducing

the output. If welding is ceased while the displays are flashing, the last values will be displayed for 10

seconds or until controls are adjusted..

Table 5-1: Power Source Problems