Transmig 250i installation/setup – Tweco 250i Transmig Inverter User Manual

Page 46

TRANSMIG 250i

INSTALLATION/SETUP

INSTALLATION/SETUP 3-28

Manual 0-5187

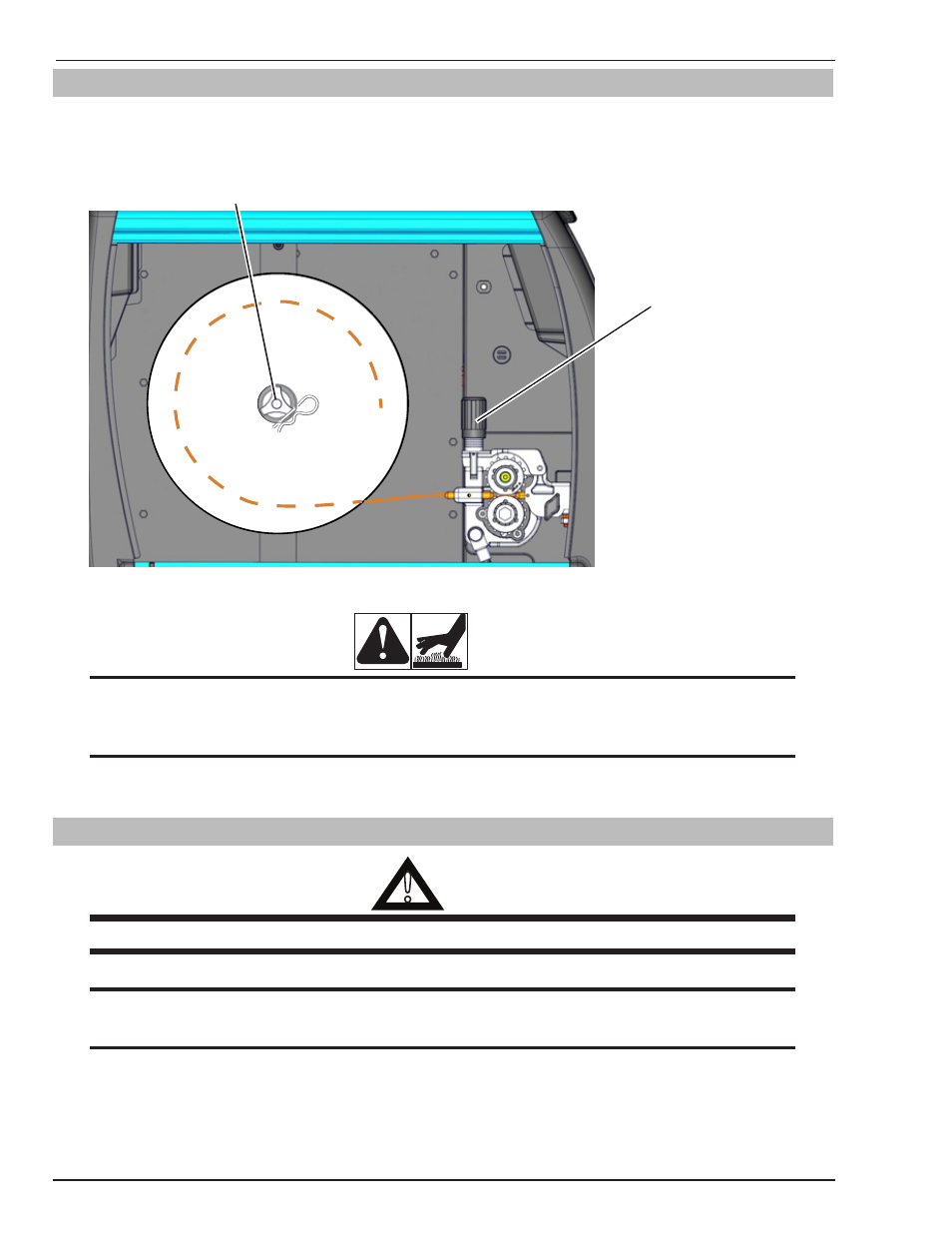

3.21 Wire Reel Brake

The wire reel hub incorporates a friction brake which is adjusted during manufacture for optimum braking. If it is

considered necessary, adjustment can be made by turning the tri-lobe nut inside the open end of the wire reel hub.

Clockwise rotation will tighten the brake. (Refer to Figure 3-25).

Pressure Adjustment

Knob

Wheel Brake adjusting tri-lobe nut

Art # A-10032

Figure 3-25: Wire Installed

CAUTION

Excessive tension on the brake will cause rapid wear of mechanical wire feed parts, over heating of electrical

componentry and possibly an increased incidence of wire Burnback into the contact tip.

NOTE

Correct adjustment will result in the wire reel circumference continuing no further than 20mm after release

of the MIG Torch trigger switch. The wire should be slack without becoming dislodged from the reel.

3.22 Shielding Gas Regulator Operating Instructions

!

WARNING

This equipment is designed for use with welding grade (Inert) shielding gases only.

NOTE

Shielding Gas Regulator not included in the Transmig 250i (Asia Version) Plant Part No W1003250M.

NOTE

Shielding Gas is not required if the unit is used with self shielded FCAW (flux cored arc welding) wires