Basic welding transmig 250i, 01 mig (gmaw/fcaw) basic welding technique – Tweco 250i Transmig Inverter User Manual

Page 57

BASIC WELDING

TRANSMIG 250I

Manual 0-5187

4-1

BASIC WELDING

SECTION 4:

BASIC WELDING GUIDE

4.01 MIG (GMAW/FCAW) Basic Welding

Technique

Two different welding processes are covered in this sec-

tion (GMAW and FCAW), with the intention of providing

the very basic concepts in using the Mig mode of weld-

ing, where a MIG Torch is hand held, and the electrode

(welding wire) is fed into a weld puddle, and the arc is

shielded by an inert welding grade shielding gas or inert

welding grade shielding gas mixture.

GAS METAL ARC WELDING (GMAW): This process, also

known as MIG welding, CO

2

welding, Micro Wire Welding,

short arc welding, dip transfer welding, wire welding etc.,

is an electric arc welding process which fuses together the

parts to be welded by heating them with an arc between

a solid continuous, consumable electrode and the work.

Shielding is obtained from an externally supplied welding

grade shielding gas or welding grade shielding gas mix-

ture. The process is normally applied semi automatically;

however the process may be operated automatically and

can be machine operated. The process can be used to

weld thin and fairly thick steels, and some non-ferrous

metals in all positions.

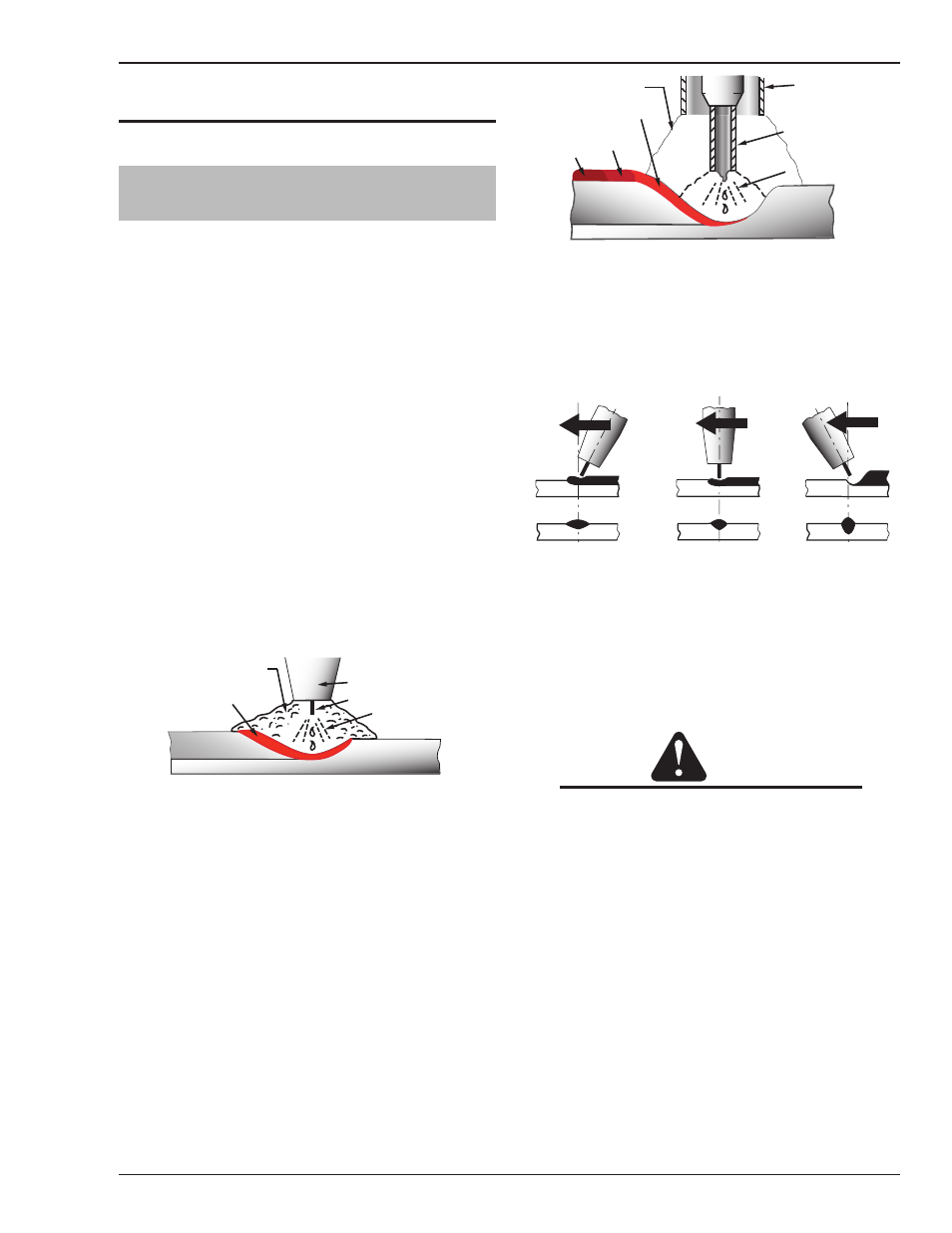

Art # A-8991_AB

Shielding Gas

Molten Weld Metal

Solidified

Weld Metal

Nozzle

Electrode

Arc

Base Metal

GMAW Process

Figure 4-1

FLUX CORED ARC WELDING (FCAW): This is an electric

arc welding process which fuses together the parts to be

welded by heating them with an arc between a continu-

ous flux filled electrode wire and the work. Shielding is

obtained through decomposition of the flux within the

tubular wire. Additional shielding may or may not be ob-

tained from an externally supplied gas or gas mixture. The

process is normally applied semi automatically; however

the process may be applied automatically or by machine. It

is commonly used to weld large diameter electrodes in the

flat and horizontal position and small electrode diameters

in all positions. The process is used to a lesser degree for

welding stainless steel and for overlay work.

Art # A-08992_AB

Molten

Slag

Nozzle

(Optional)

FCAW Process

Flux Cored

Electrode

Arc

Shielding Gas

(Optional)

Slag

Molten Metal

Base Metal

Solidified

Weld Metal

Figure 4-2

Position of MIG Torch

The angle of MIG Torch to the weld has an effect on the

width of the weld.

Push

Vertical

Drag/Pull

Art # A-07185_AB

Figure 4-3

The MIG Torch should be held at an angle to the weld joint.

(See Secondary Adjustment Variables below)

Hold the MIG Torch so that the welding seam is viewed

at all times. Always wear the welding helmet with proper

filter lenses and use the proper safety equipment.

CAUTION

Do NOT pull the MIG Torch back when the

arc is established. This will create excessive

wire extension (stick-out) and make a very

poor weld.

The electrode wire is not energized until the MIG Torch

trigger switch is depressed. The wire may therefore be

placed on the seam or joint prior to lowering the helmet.