Problems/service transmig 250i, 01 power source problems – Tweco 250i Transmig Inverter User Manual

Page 79

PROBLEMS/SERVICE

TRANSMIG 250i

Manual 0-5187

5-1

PROBLEMS AND ROUTINE SERVICE

SECTION 5: POWER SOURCE PROBLEMS AND ROUTINE SERVICE

REQUIREMENTS

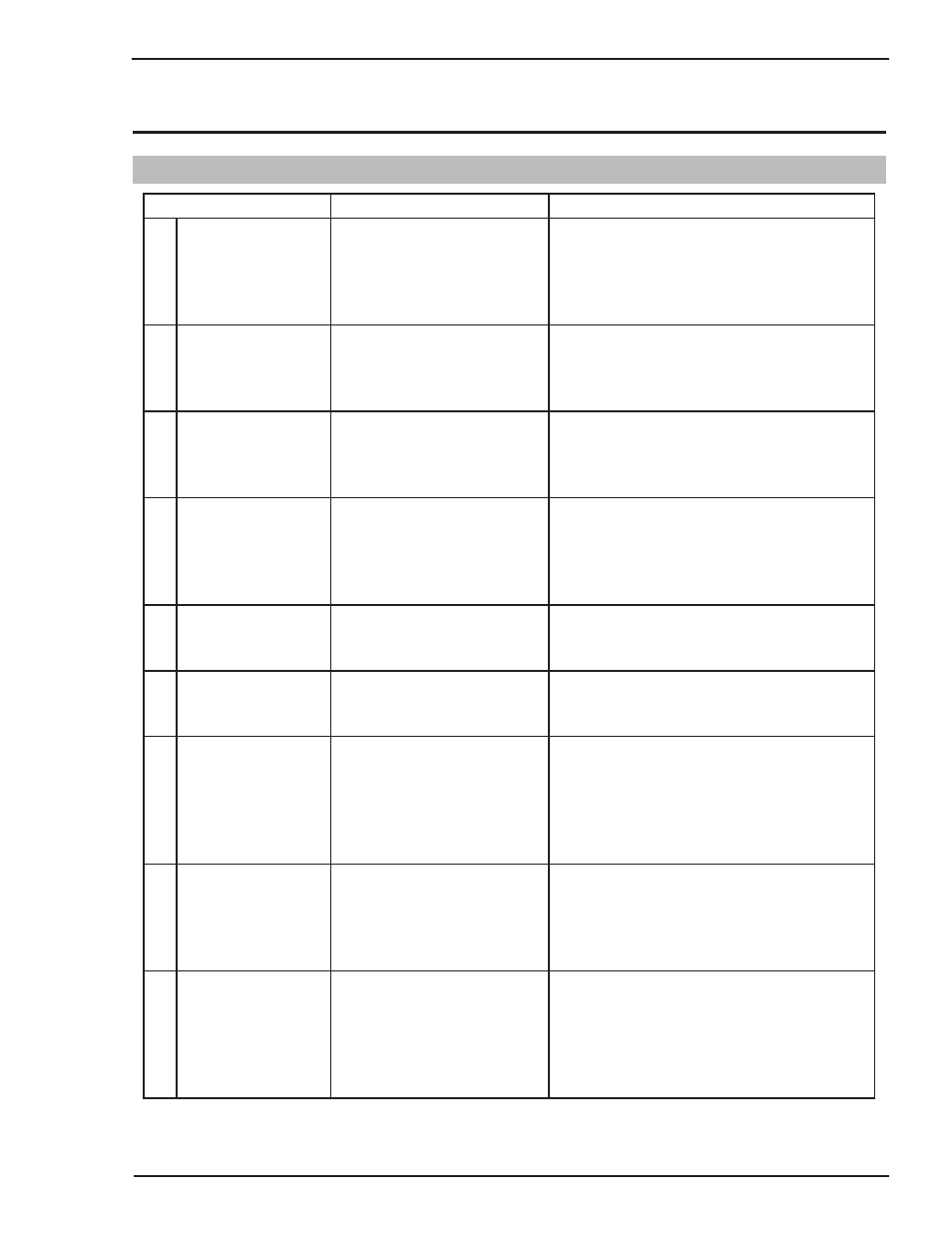

5.01 Power Source Problems

Error Code

CAUSE

REMEDY

1

Over Temperature

Fault

OverTemp signal from

Power board indicates Over

temperature fault condition of

power components

A. Decrease duty cycle of welding activity

B. Ensure that air vents are not blocked/

obstructed

C. Consult an Accredited CIGWELD Service

Provider.

2

Input Power Fault

Supply OK signal from Power

board indicates input power

voltage is out of range (too

high or too low)

A. Check input power connections and cables

for damage or improper insertion

B. Verify input voltage levels meet product

requirements

3

VBIAS Voltage Low

Fault

Controller board circuit

monitor indicates VBIAS

voltage too low

(< 13.7 VDC)

Consult an Accredited CIGWELD Service

Provider.

4

Ground Fault

Excessive current detected

on Ground wire of power

connection

A. Isolate welder chassis from work piece.

Check workpiece ground connection.

B. Check for MIG wire feed problem in spool/

feedplate. Verify wire is not contacting

chassis.

9

Fan Fault

Cooling Fan Failure detected

on Inverter board

A. Examine fan vents for potential obstruction.

B. Consult an Accredited CIGWELD Service

Provider.

10 Inverter Output Fault Substandard output voltage

condition detected by

controller before weld started

Consult an Accredited CIGWELD Service

Provider.

11

VRD Fault

Insufficient Voltage for

electrode contact detection by

controller

A. Check all welding cable connections, cable

and MIG Torch/electrode holder integrity.

Remove any potential short circuits before

restoring power.

B. Consult an Accredited CIGWELD Service

Provider.

14

Trigger Fault

Fault occurred detecting

trigger state/condition

A. Trigger may be already activated when MIG

process mode is selected - verify that trigger

is not accidentally activated

B. Trigger may be faulty and/or dirty, test and

replace MIG Torch/trigger device

15

Wirefeed Fault

Welder detects prolonged

open circuit during MIG weld

A. Inspect MIG wire spool and feedplate for

improper tension or 'bird's nest'.

B. Inspect MIG Torch and cable for damage or

obstruction

C. Consult an Accredited CIGWELD Service

Provider.