Installation/setup transmig 250i – Tweco 250i Transmig Inverter User Manual

Page 51

INSTALLATION/SETUP

TRANSMIG 250i

Manual 0-5187

3-33 INSTALLATION/SETUP

11. Refer to the Weld Guide located on the inside of the wire feed compartment door for further information on

Voltage/Wirespeed settings.

WARNING

Before connecting the work clamp to the work make sure the mains power supply is switched OFF.

Secure the welding grade shielding gas cylinder in an upright position by chaining it to a suitable stationary

support to prevent falling or tipping.

CAUTION

Loose welding terminal connections can cause overheating and result in the male plug being fused in the

terminal.

Remove any packaging material prior to use. DO NOT block the air vents at the front or rear of the Welding

Power Source.

NOTE

Depending on the type of wire you will be using the MIG Torch polarity may need to be switched. Follow

the wire manufacturers recommendation.

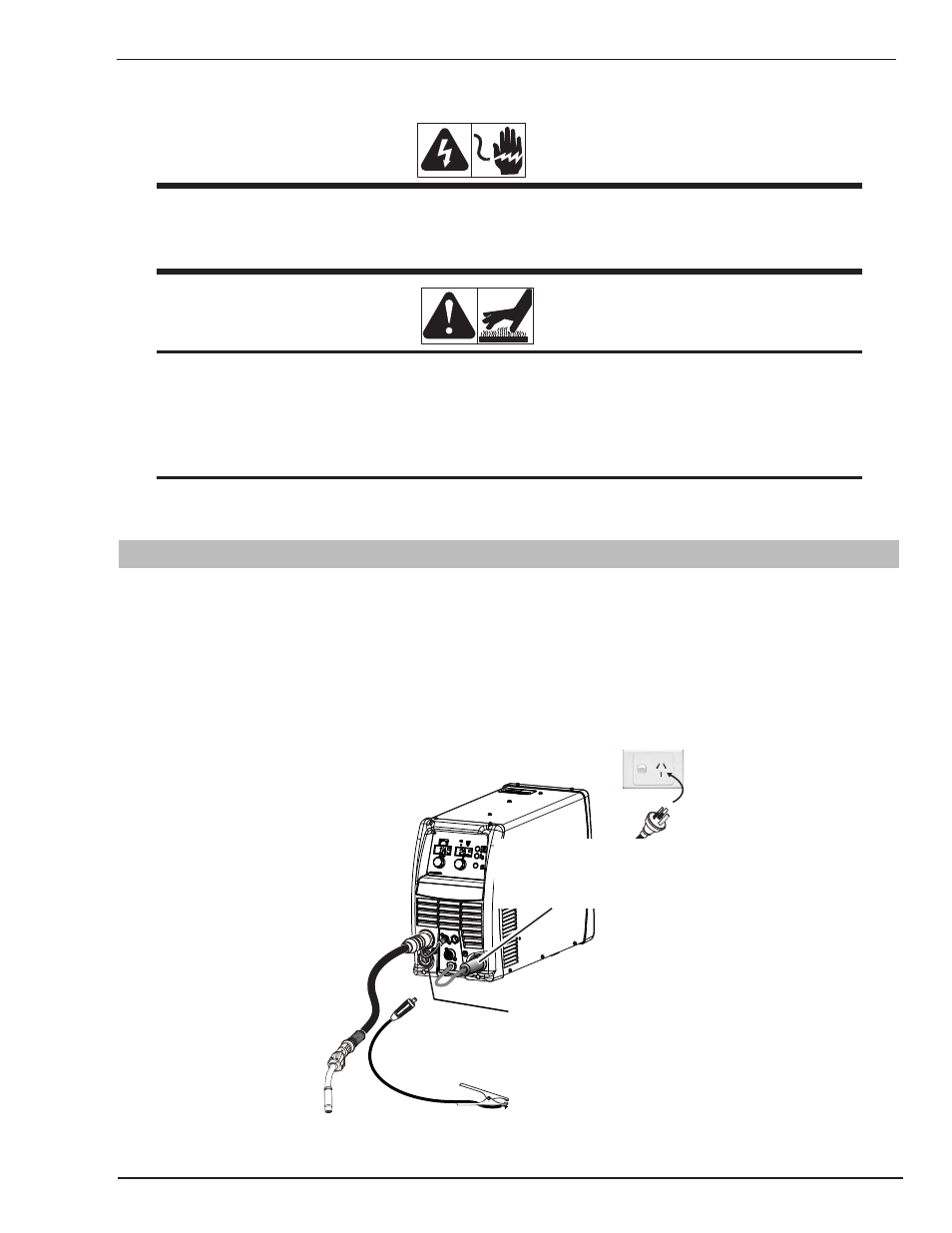

3.24 Set-up for MIG (FCAW) Welding with Gasless MIG Wire

The Transmig 250i is supplied with a Tweco Fusion 250 AMP air-cooled MIG Torch. The Fusion MIG Torch is designed

with an ergonomic handle and fewer parts to cause performance problems. The Fusion MIG Torch uses standard

readily available Tweco consumable parts.

When using a gasless flux cored wire, you do not need to have an external gas source attached to the unit. If one is,

then make sure it is turned OFF.

For most Self Shielded Flux Cored Wire, connect the Work Lead to the positive + terminal and connect the MIG Torch

polarity lead to the negative - terminal.

Art # A-10283

+

-

Connect MIG Torch Polarity

Terminal to -/Negative

(Dinse

®

type 50mm)

Positive Output

Terminal

(Dinse

®

type 50mm)

Figure 3-30: MIG Torch Polarity Negative