Transmig 250i installation/setup – Tweco 250i Transmig Inverter User Manual

Page 26

TRANSMIG 250i

INSTALLATION/SETUP

INSTALLATION/SETUP 3-8

Manual 0-5187

which case the unit will revert to preview mode, (2) welding is recommenced, in which case actual welding amperage

will be displayed, or (3) a period of 10 seconds elapses following the completion of welding in which case the unit

will return to preview mode.

The display is also used for providing error messages to the user and showing other information, which will be ex-

plained in Section 5.

11. MIG Torch Adaptor (Euro Style)

The MIG Torch adaptor is the connection point for the MIG welding Torch. Connect the MIG Torch by pushing the

MIG Torch connector into the brass MIG Torch adaptor firmly and screwing the plastic MIG Torch nut clockwise

to secure in position. To remove the MIG Torch simply reverse these directions.

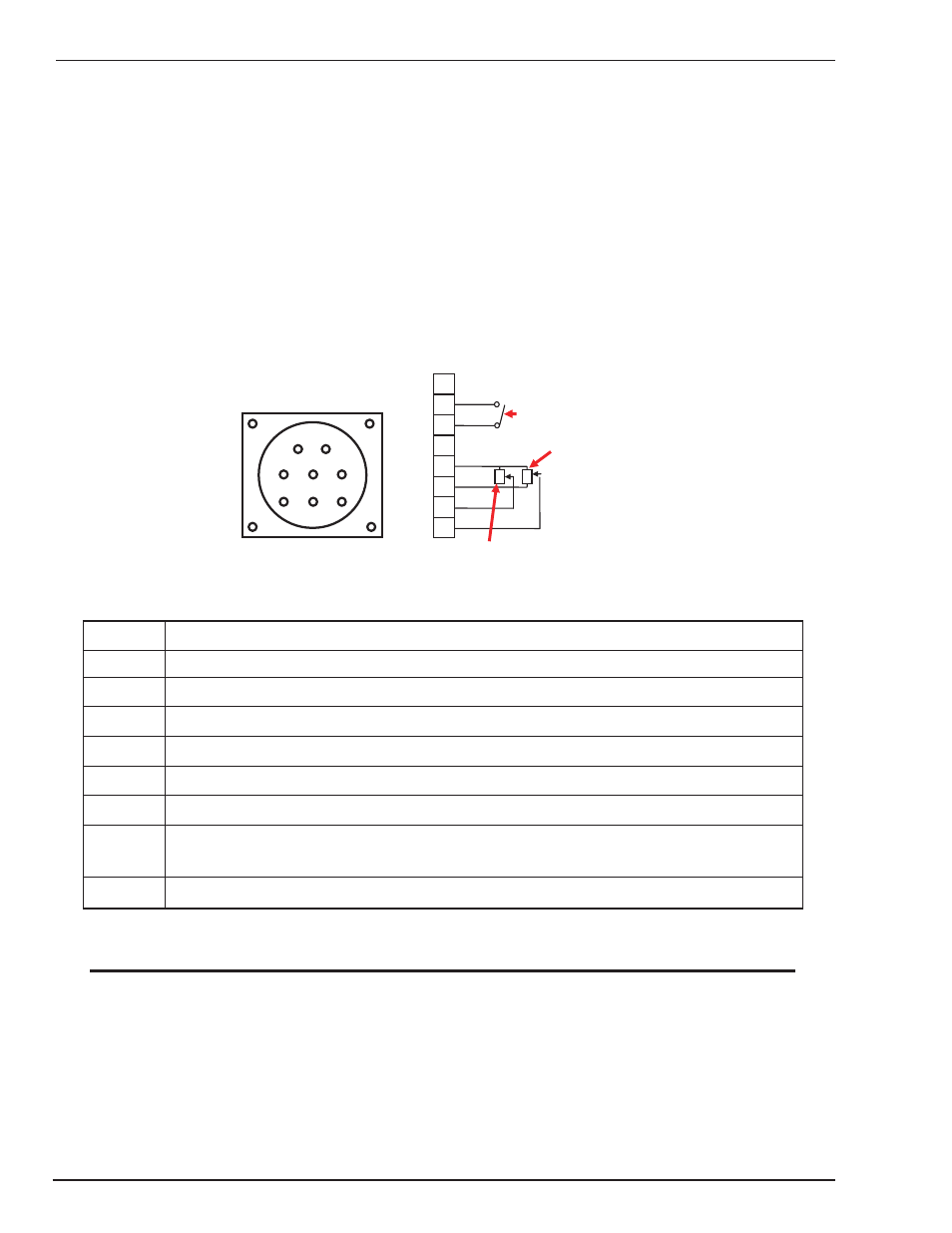

12. Remote Control Socket

The 8 pin Remote Control Socket is used to connect remote control devices to the welding power source. To make

connections, align keyway, insert plug, and rotate threaded collar fully clockwise.

2

1

8

7

6

3

4

5

Trigger Switch

Remote Wirespeed in GMAW mode

Remote Amps in GTAW mode

Remote Volts in

GMAW Mode

1

2

3

4

5

6

7

8

W

V

A-09594

Figure 3-3: Remote Control Socket

Socket Pin

Function

1

Not connected

2

Trigger Switch Input

3

Trigger Switch Input

4

Not connected

5

5k ohm (maximum) connection to 5k ohm remote control potentiometer.

6

Zero ohm (minimum) connection to 5k ohm remote control potentiometer.

7

Wiper arm connection to 5k ohm remote control Wirespeed MIG mode potentiometer. Wiper

arm connection to 5k ohm remote control Amps LIFT TIG mode potentiometer.

8

Wiper arm connection to 5k ohm remote control Volts MIG mode potentiometer.

Table 3-3

NOTE

The remote local setting on the control panel should be set to remote for the remote wire feeder amperage/

voltage controls to be operative.