Basic welding transmig 250i – Tweco 250i Transmig Inverter User Manual

Page 75

BASIC WELDING

TRANSMIG 250I

Manual 0-5187

4-19

BASIC WELDING

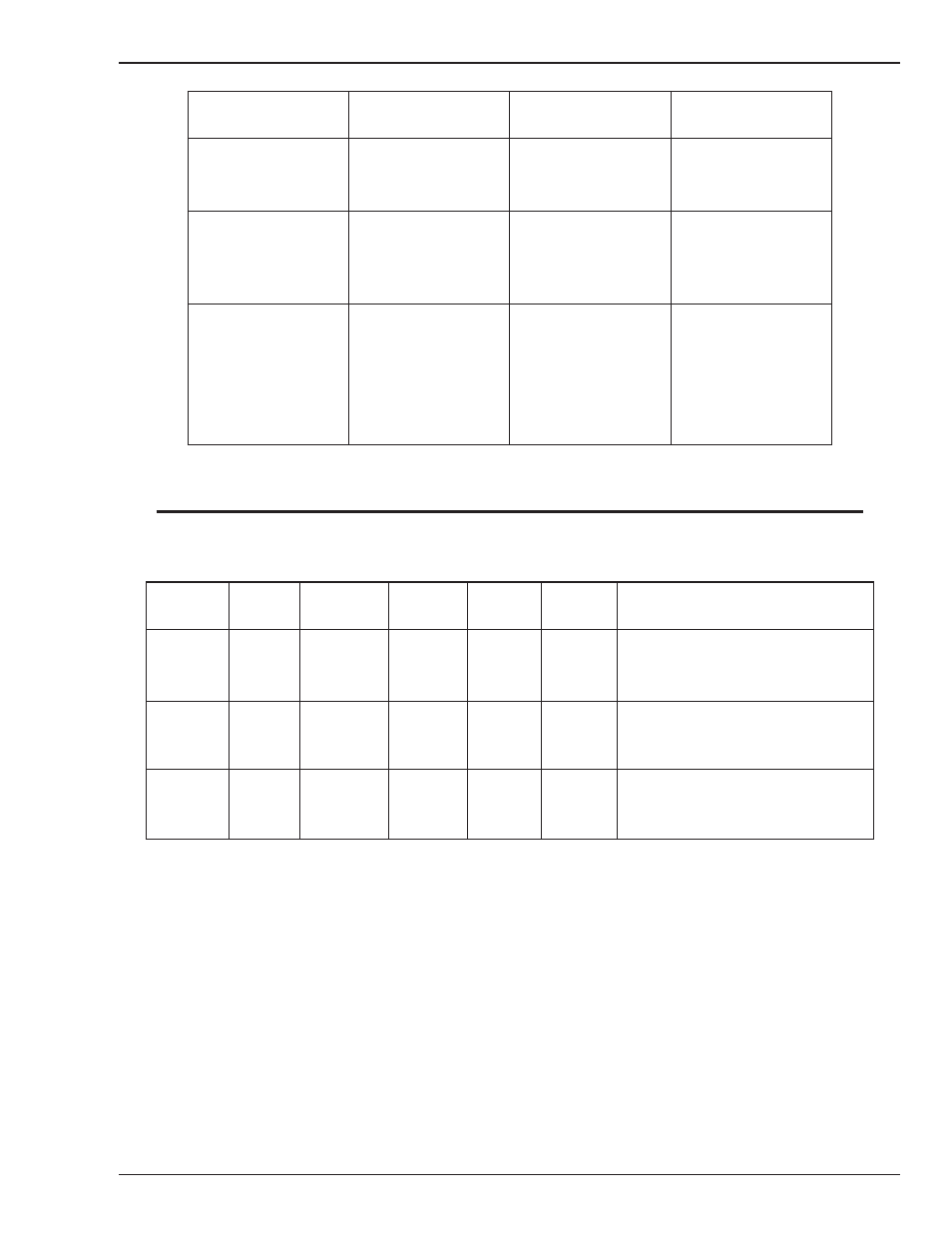

Tungsten Electrode Types

Electrode Type

(Ground Finish)

Welding Application

Features

Colour Code

Thoriated 2%

DC welding of mild

steel, stainless steel

and copper

Excellent arc starting,

Long life, High current

carrying capacity

Red

Zirconated 1%

High quality AC weld-

ing of aluminium,

magnesium and their

alloys.

Self cleaning, Long

life, Maintains balled

end, High current car-

rying capacity.

White

Ceriated 2%

AC & DC welding of

mild steel, stainless

steel, copper, alumin-

ium, magnesium and

their alloys

Longer life, More

stable arc, Easier

starting, Wider current

range, Narrower more

concentrated arc.

Grey

Table 4-8

NOTE

The Transmig 175i Inverter is not suited for AC Tig welding.

TIG Welding Filler Rods

Comweld

Rod

Aust Std AWS Std

Part No.

1.6mm

Part No.

2.4mm

Part No.

3.2mm

Type/Application

LW1

LW1-6

Supersteel

R4

R6

R2

ER70S-4

ER70S-6

ER70S-2

321411

321417

321370

—

—

—

—

—

—

For mild-medium strength steels.

Pipes, tubing, roll cages, etc.

CrMo1

CrMo2

RB2

RB3

ER80S-B2

ER90S-B3

—

—

321379

321383

—

—

For welding of high strength Cr-Mo

steels used at elevated tempera-

tures.

308L

309L

316L

R308L

R309L

R316L

ER308L

ER309L

ER316L

321406

321403

321400

321407

321404

321401

—

—

—

For stainless steels. Stainless pipes,

tubing, architectural uses, etc.

Table 4-9