Basic welding transmig 250i – Tweco 250i Transmig Inverter User Manual

Page 71

BASIC WELDING

TRANSMIG 250I

Manual 0-5187

4-15

BASIC WELDING

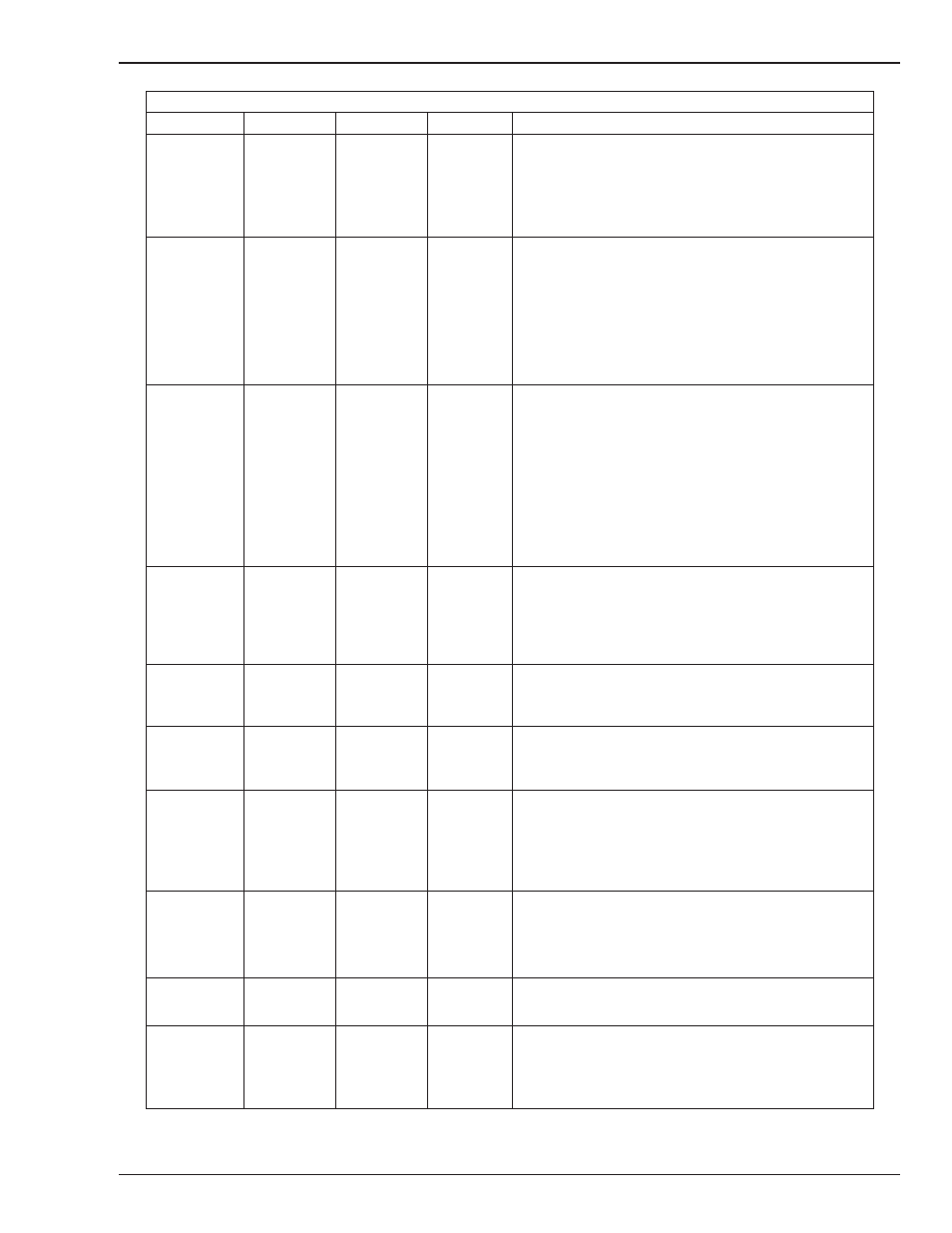

Electrode Selection Chart

CIGWELD Electrode Selection Chart

Description

Diameter

Pack

Part No.

Application

Satincraft 13

2.5mm

2.5mm

3.2mm

3.2mm

4.0mm

1kg

2.5kg

1kg

2.5kg

5kg

322135

612182

322136

612183

611184

General purpose electrode suitable for all positional welding and

galvanised steel.

Ferrocraft 12XP

2.0mm

2.0mm

2.5mm

2.5mm

3.2mm

3.2mm

4.0mm

1kg

2.5kg

1kg

2.5kg

1kg

2.5kg

5kg

322128

612231

322129

612232

322138

612233

611234

General purpose, Xtra performance electrode recommended for all

positional (inc. Vertical down) welding of mild and galvanised steel.

WeldSkill GP

2.0mm

2.0mm

2.5mm

2.5mm

2.5mm

3.2mm

3.2mm

3.2mm

4.0mm

1 kg

2.5 kg

1 kg

2.5 kg

5 kg

1 kg

2.5 kg

5 kg

5 kg

WEG1020

WEG2520

WEG1025

WEG2525

WEG5025

WEG1032

WEG2532

WEG5032

WEG5040

User-friendly GP electrode for welding thin section mild and galvanised

steels. Excellent for vertical down fillet welding applications.

Ferrocraft 16

Twincoat

2.5mm

2.5mm

3.2mm

3.2mm

4.0mm

2.5 kg

5 kg

2.5 kg

5 kg

5 kg

612752

611752

612753

611753

611754

Hydrogen Controlled type offering exceptional AC/DC performance in

all welding positions.

Satincrome

308L-17

2.5mm

3.2mm

4.0mm

2.5 kg

2.5 kg

2.5 kg

611602

611603

611604

Stainless Steel type for 19Cr/10Ni stainless grades including 201,

202, 301, 302, 303, 304, 304L, 305, 308, etc

Satincrome

309Mo-17

2.5mm

3.2mm

4.0mm

2.5 kg

2.5 kg

2.5 kg

611692

611693

611694

Stainless Steel type for 309 and 309L grades. It is also suitable for

welding of dissimilar welding of other 300 series stainless steels.

Satincrome

316L-17

2.0mm

2.5mm

3.2mm

2.5/3.2mm

4.0mm

2,5 kg

2.5 kg

2.5 kg

Blisterpack

2.5 kg

611661

611662

611663

322215

611664

Stainless Steel type for welding of matching Mo bearing grades, 316

and 316L.

Weldall

2.5mm

3.2mm

2.5/3.2mm

4.0mm

2.5 kg

2.5 kg

Blisterpack

2.5 kg

611702

611703

322216

611704

High alloy stainless steel type for welding of unknown steels, repair of

die or tool steels and for joining dissimilar steels. (Not recommended

for cast iron).

Castcraft 55

3.2mm

4.0mm

2.5 kg

2.5 kg

611723

611724

For repair and maintenance welding of S.G. cast iron, meehanite and

other cast irons. It produces high strength weld than Castcraft 100.

Castcraft 100

2.5mm

3.2mm

2.5/3.2mm

4.0mm

2.5 kg

2.5 kg

Blisterpack

2.5 kg

611732

611733

322217

611734

Soft, Ductile Nickel type electrode for repair and maintenance welding

of a wide range of cast irons. It has better “wetting” action than

Castcraft 55.

Table 4-4: Cigweld Electrode Selection Chart

Further information on CIGWELD electrodes can be found at the website www.thermadyne.com.