Transmig 250i installation/setup – Tweco 250i Transmig Inverter User Manual

Page 24

TRANSMIG 250i

INSTALLATION/SETUP

INSTALLATION/SETUP 3-6

Manual 0-5187

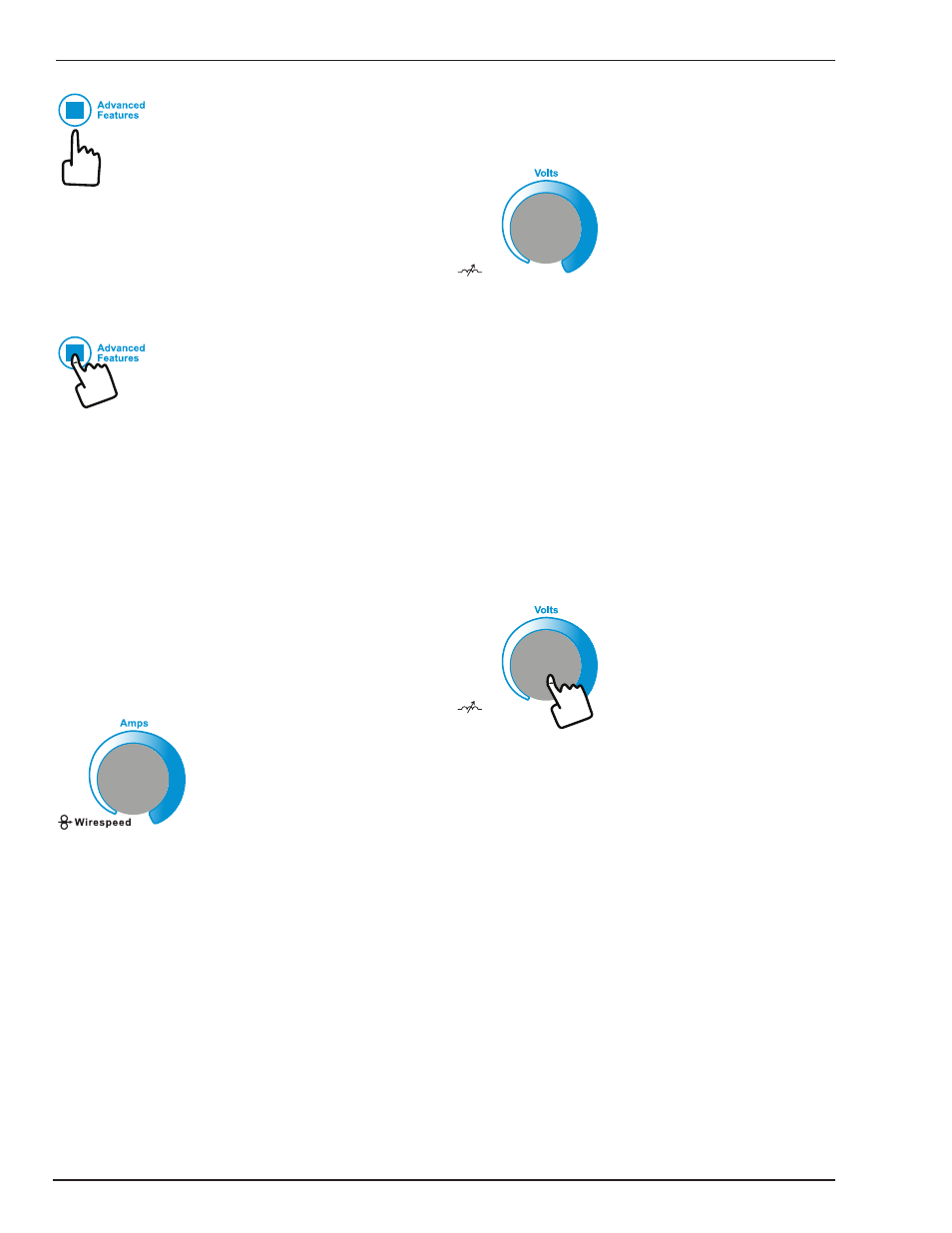

6. Advanced Features Button

Press and release the Advanced Features button to enter

or exit from the advanced programming mode. To exit,

simply press and release the button again. Any changes

made are saved. The advanced programming menu items

are described in detail for each welding mode in Section

3.07.

Gas Purge.

In addition, the Advanced Features Button is used to initi-

ate a 30 second gas line purge function to fill the gas line

with the shielding gas from the connected gas cylinder.

To start the gas purge function, simply press and hold the

button for approximately two (2) seconds. Once the Gas

purge function has started, a countdown timer will show

in the left alpha-numeric display indicating the number

of seconds remaining before the purge will be automati-

cally terminated. You can stop the Gas purge any time

during the 30 seconds by quickly pressing and releasing

the button again.

7. Left Knob: Amperage Control (Wirespeed)

Left Knob

The amperage control knob adjusts the amount of welding

current delivered by the power source. In STICK and LIFT

TIG modes, the amperage control knob directly adjusts the

power inverter to deliver the desired level of output cur-

rent. In MIG mode, the amperage knob adjusts the speed

of the wire feed motor (which in turn adjusts the output

current by varying the amount of MIG wire delivered to

the welding arc). The optimum wire speed required is

dependent on the type of welding application. The setup

chart on the inside of the wire feed compartment door

provides a brief summary of the required output settings

for a basic range of MIG welding applications. The value

may also be adjusted while a weld is in progress – if this

occurs, the left display will briefly switch to show the ad-

justed value as the knob is turned, and will automatically

revert back to showing the weld current measurements

when the knob is not being turned.

8. Right Knob: Multifunction Control - MIG Voltage /

Arc Control (Inductance) & STICK Arc Force

Right Knob

Push For Inductance

Arc Control

MIG Voltage Control

In this mode the control knob is used to adjust the out-

put voltage of the power source. The welding voltage is

increased by turning the knob clockwise or decreased

by turning the knob anti-clockwise. The optimum volt-

age level required is dependent on the type of welding

application. The setup chart on the inside of the wire

feed compartment door provides a brief summary of the

required output settings for a basic range of MIG welding

applications. The value may also be adjusted while a weld

is in progress – if this occurs, the left display will briefly

switch to show the adjusted value as the knob is turned,

and will automatically revert back to showing the weld

current measurements when the knob is not being turned.

Push For Inductance

Arc Control

Right Knob

MIG Arc Control (Inductance)

The arc control operates in MIG mode only and is used

to adjust the intensity of the welding arc. To access the

Arc Control function, push inward on the right knob and

hold it for approximately 2 seconds. This feature can be

accessed and adjusted during welding.

When STICK Mode is Selected

In this mode the multifunction control knob is used to

adjust arc force. Arc force control provides an adjustable

amount of welding force (or “dig”) control. This feature

can be particularly beneficial in providing the operator the

ability to compensate for variability in joint fit-up in certain

situations with particular electrodes. In general increasing

the arc force control toward ‘100%’ (maximum arc force)

allows greater penetration control to be achieved. Arc

force is increased by turning the control knob clockwise

or decreased by turning the knob anti-clockwise. This

feature can be accessed and adjusted during welding.