Transmig 250i installation/setup, 07 advanced features details – Tweco 250i Transmig Inverter User Manual

Page 28

TRANSMIG 250i

INSTALLATION/SETUP

INSTALLATION/SETUP 3-10

Manual 0-5187

15. Negative Welding Output Terminal

The negative welding terminal is used to connect the

welding output of the power source to the appropriate

welding accessory such as the MIG Torch (via the MIG

Torch polarity lead), TIG torch or work lead. Negative

welding current flows to the power source via this

heavy duty bayonet type terminal. It is essential,

however, that the male plug is inserted and turned

securely to achieve a sound electrical connection.

CAUTION

Loose welding terminal connections can cause

overheating and result in the male plug being

fused in the bayonet terminal.

16. MIG Torch Polarity Lead

The polarity lead is used to connect the MIG Torch to

the appropriate positive or negative output terminal

(allowing polarity reversal for different welding ap-

plications). In general, the polarity lead should be

connected in to the positive welding terminal (+) when

using steel, stainless steel or aluminium electrode

wire. When using gasless wire, the polarity lead is

generally connected to the negative welding termi-

nal (-). If in doubt, consult the manufacturer of the

electrode wire for the correct polarity. It is essential,

however, that the male plug is inserted and turned

securely to achieve a sound electrical connection.

CAUTION

Loose welding terminal connections can cause

overheating and result in the male plug being

fused in the bayonet terminal.

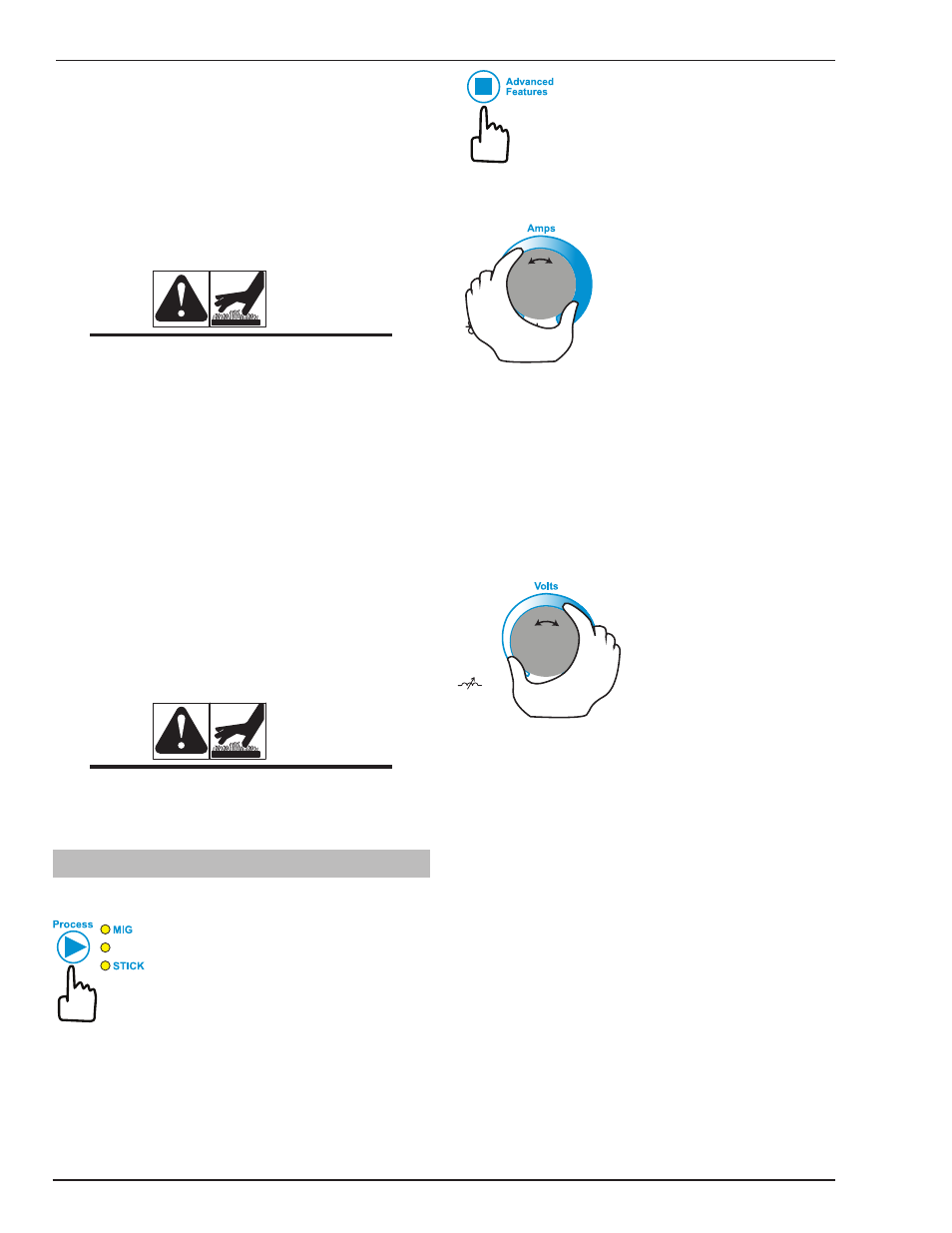

3.07 Advanced Features Details

General Operation

LIFT TIG

Select the weld process (Control No 4) you wish to view

Advanced Features for.

Then press and release the Advanced

Features button (Control No 6) to enter or

exit from the Advanced Features programming function

of the welder.

Left Knob

The Advanced Features menu items are viewed by turning

the left knob (Control No 7) to move forward or backward

through the list. The function names in the menu will be

displayed in abbreviated form in the left alpha-numeric

display. In the case of two part names or abbreviations,

the left display will alternately flash the first part of the

function name and then the second part, followed by a

brief “blank” interval. For each function, the right alpha-

numeric display will show its present value.

Push For Inductance

Arc Control

Right Knob

To change the value of that parameter, simply turn the

right knob (Control No 8) to change it. If the setting has

been changed from its previous value the welder will save

the new value when the left knob is turned to view the

next parameter, or if the user activates a control to cause

the welder to exit Advanced Features mode as described

earlier. Once the beginning or end of the menu list is

reached, additional turning of the left knob in that direction

will not result in any change of the displayed parameter.

The Advanced Features control functions are in order with

the user’s process steps when setting up to operate the

welder in the selected welding process modes (MIG, LIFT

TIG, STICK). The menu functions shown in Advanced

Features Mode are mostly dependent on the currently

selected weld process mode of the machine.