04 error codes, 04 error codes -4 – Tweco 500SP PowerMaster Automation User Manual

Page 72

POWERMASTER 400SP, 500SP AUTOMATION

7-4

March 16, 2007

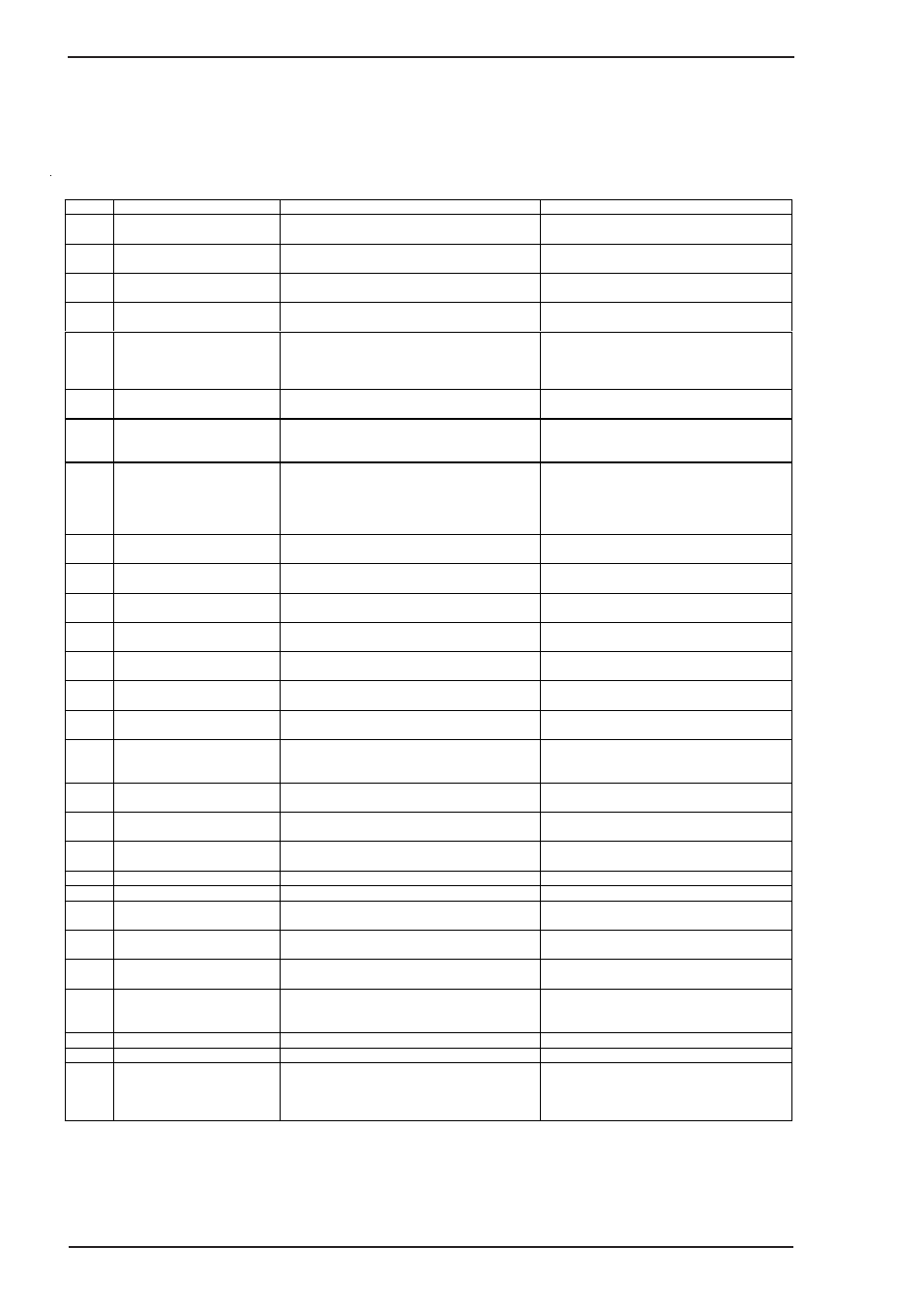

7.04 Error Codes

In case of a malfunction, an error code is indicated on the digital multifunction display (54) and the corre-

sponding error description appears on the LCD display (50). As long as an error code is indicated, welding

operation is not possible.

*1 Check module temperatures in menu Extras, Diagnosis > Module temperatures

*2 Check supply voltages in menu Extras, Diagnosis > Operating voltages

*3 Check the flow rate in menu Extras, Diagnosis > Flow rate cooling system

Code Description

Cause

Remedy

E01

Thermal overload

Thermal sensor of power unit measures a too

high temperature (>176°F)

Let machine cool down in standby (*1)

Check temperature sensor (short circuit)

E02

Mains overvoltage

Mains voltage too high (24V supply > 36V)

Check mains voltage and control

transformer (*2)

E03

Secondary over-current

Welding current is too high

Notify an accredited Thermal Arc Service

Provider for repair

E04

Air cooling error

Temperature sensor of the power unit

detects that the unit heats up too fast

Check fans and their wiring

E05

Cooling system error

Flowrate of the cooling liquid is too low (< 0,3

l/min)

Pump is not working

Check connectors of flow-meter, level of

cooling liquid and flowrate (*3)

Check fuse SI7 (2,5A) on pc-board MV-

MAPRO

E06

Secondary overvoltage

Master detects output voltage is too high

(>100V)

Notify an accredited Thermal Arc Service

Provider for repair

E07

EEProm checksum error

No welding program stored or error during

reading from memory

Transfer welding programs to machine

again, exchange MV-MAPRO if error still

persists

E08

Wire feed / tacho

Power consumption of wire feed motor too

high

No tacho signal

No CAN-Bus connection between MAPRO

and DMR

Blow out torch package with compressed

air

Check wire feed unit

Check wiring of wire feed motor and PC-

board DMR

E09

Error v/a measuring

Measuring difference between Master and

Process

Check wiring of pc-board LSW, pc-board

DP-EMV and PC-board DP-UFI-BO

E11

Remote-control connection

Short circuit between remote control cables

Check remote control and wiring of remote

control socket

E12

Communication Process

Process is not responding to Master

Switch the machine off and on again

Optionally exchange PC-board DP-MAPRO

E13

Temp. sensor error

Temp. sensor is defective

Notify an accredited Thermal Arc Service

Provider for repair

E14

Op. voltages error

Supply voltage is too low (< 17V)

Check mains voltage and control

transformer (*2)

E16

Overcurrent protection1

Power consumption of power unti 1 is too

high

Notify an accredited Thermal Arc Service

Provider for repair

E17

Op. voltage 18V error

18 V from control transformer missing

Check mains supply and control

transformer

E18

overload protection

Safety shutdown to protect electrical

components

Temp. sensor is disconnected

Let machine cool down in standby

Check temp. sensor

E19

Power module error

Chargeup time for capacitors >1 second

Check mains input

Check MVPWRUP board and it’s wiring

E20

Overvoltage sec.

Process reports a too high output voltage or

no voltage

Notify an accredited Thermal Arc Service

Provider for repair

E21

Output voltage/current

External current/voltage or measure-

difference between Master and Process

Notify an accredited Thermal Arc Service

Provider for repair

E22

Mains undervoltage 1

Power unit 1 reports mains voltage too low

Check mains voltage and mains rectifier

E23

Mains overvoltage

Power unit reports mains voltage too high

Check mains voltage

E24

Overcurrent protection2

Power consumption of power unti 2 is too

high

Notify an accredited Thermal Arc Service

Provider for repair

E25

Power module detection

DIP-switch on pc-board MVDRV have been

set wrong

Notify an accredited Thermal Arc Service

Provider for repair

E26

Error voltage symmetry

DC-link voltage difference (>50V) between

power units

Notify an accredited Thermal Arc Service

Provider for repair

E27

No program (DSP)

Wrong material-wire-gas combination

Welding programs faulty or not available

Select other material-wire-gas combination

Transfer welding programs to machine

again

E30

Op. voltage 15V error

Supply voltage is too low

Check mains voltages

E31

Communication error

Master is not responding to Process

Switch the machine off and on again

?

A “?“ is shown in the display The display board doesn’t get any data from

the MV-MAPRO

Check the flat ribbon cable of the DS20BF

Check interpass hose (only machines with

separate wire feeder) and it’s connectors

Check PC-boards DMR and MV-MAPRO