02 system troubleshooting guide, 02 system troubleshooting guide -2 – Tweco 500SP PowerMaster Automation User Manual

Page 70

POWERMASTER 400SP, 500SP AUTOMATION

7-2

March 16, 2007

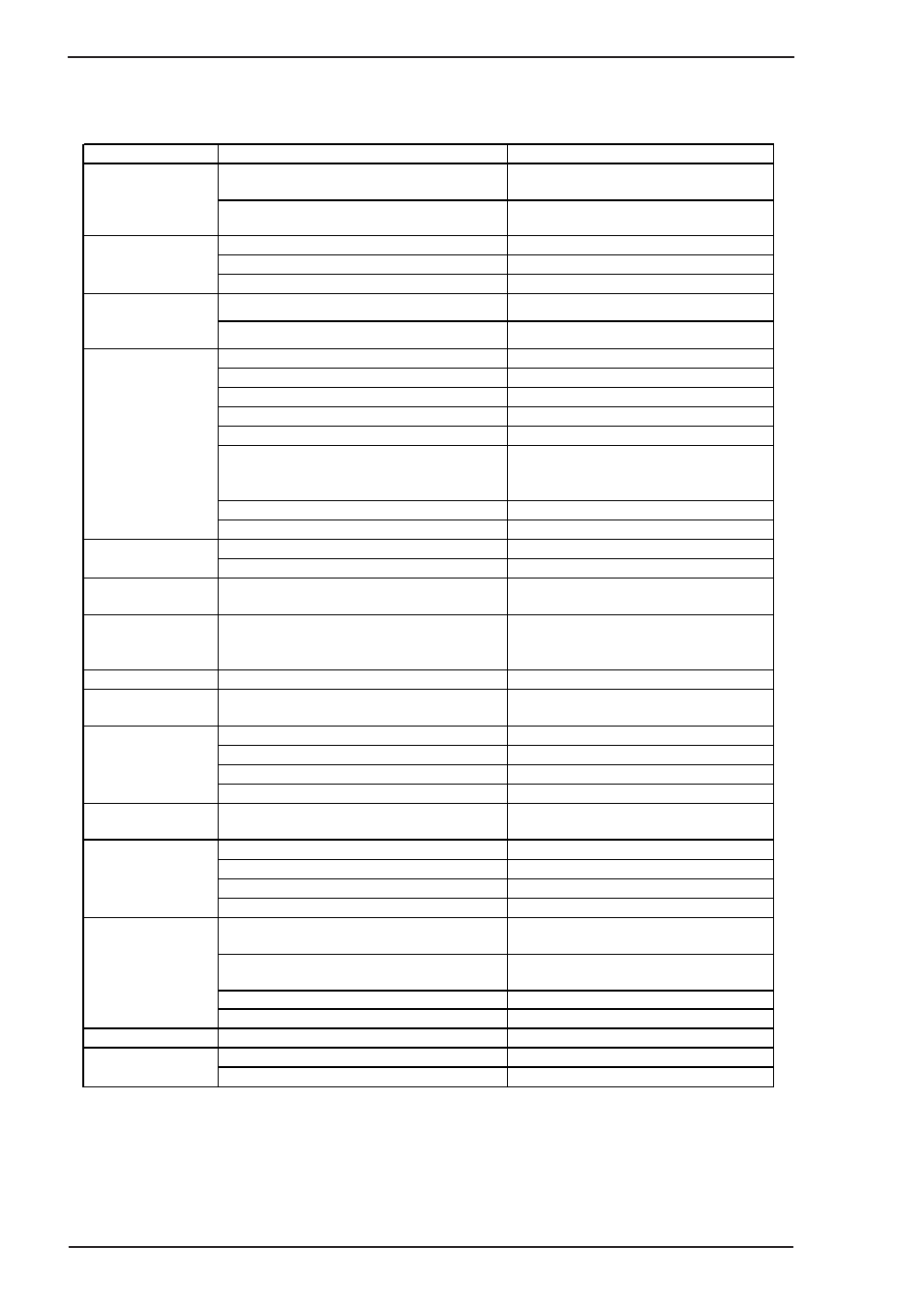

7.02 System Troubleshooting Guide

Symptom

Cause

Remedy

Insufficient coolant through flow due to pollution in

coolant

Flush the coolant hoses of the torch in opposite

direction

Contact tip is not tight or the wrong size for the wire

used

Check it

Nut of the torch hose is not tight

Tighten it

No connection of the control cable in the torch hose Check and change if necessary

Overload of the unit and thermal protection operates Allow unit to cool down at no load

Wire electrode is tight at the spool

Check and change if necessary

Burr at the wire beginning

Cut burr from end of wire

Wrong contact pressure at the wire-feed rolls

Adjust it as described in the manual

Torch defective

Check and change if necessary

No intermediate guide or is dirty

Install or clean the intermediate guide

Bad quality of welding wire

Check and change if necessary

Rust formation on the welding wire

Check and change if necessary

Torch liner is dirty inside

Disconnect the torch from the machine, unscrew

the contact tip and clean the liner with

compressed air

Torch liner is defective

Check and change if necessary

Motor brake adjusted too strong

Adjust as described in the manual

Duty cycle overloaded

Allow the machine to cool down

Poor cooing of internal unit parts

Check the air in and outlet

Cooler, hoses or pump

are damaged

Frozen systems due to low concentration of

recommended coolant in re-circulator

Contact the nearest service facility

Arc or short circuit

between contact tip and

gas nozzle

Spatter built up inside the gas nozzle

Remove it with special pliers

Unstable arc

Wrong diameter contact tip or worn out

Change contact tip

The

Control Panel is

completely blank

Primary power phase missing

Check the unit at another power outlet. Check

power cable and mains fuses/circuit breakers

Gas cylinder empty

Replace it

Defective torch

Check and replace it

Gas regulator dirty or defective

Check and replace it

Valve of gas cylinder defective

Replace the gas cylinder

Shielded gas switches

not off

Valve of gas cylinder dirty or does not close

Remove torch and gas regulator and clean it

with compressed air

Incorrect setting of shielded gas

Adjust as described in the manual

Dirty gas regulator

Check valve

Torch, gas hose blocked or not air-tight

Check and change if necessary

Shielded gas is blown away from draught

Avoid draught

Phase missing

Check the unit at another power outlet. Check

power cable and mains fuses/circuit breakers

Poor Work lead connection

Ensure good electrical contact between Work

clamp and workpiece

Work lead not plugged in right

Fasten work lead by turning the plug to the right

Defect torch

Repair or replace it

Hot plug of work lead

Plug was not tightened by turning to the right

Check

Wire rolls do not fit the wire diameter

Install correct wire rolls

Wrong contact pressure at wire feeder

Adjust as described in the manual

Torch too hot

No function when torch

button is pressed

Irregular wire feeding

or wire welds to the

contact tip

Irregular wire feeding

or no wire feeding

Higher wire wear out at

wire-feeding unit

Unit switches off

No shielded gas

Not enough shielded

gas

Decreased welding

performance