03 analog inputs, 03 analog inputs -2 – Tweco 500SP PowerMaster Automation User Manual

Page 50

POWERMASTER 400SP, 500SP AUTOMATION

5-2

March 16, 2007

5.03 Analog Inputs

The eight analog inputs are designed for a voltage of 0 to +10V DC. Programming the analog inputs (assign-

ment to welding parameters) is made with a PC with CAN interface (see PC Program Robot Tool) or directly at

the power source over the front panel (menu Extras, Robot Interface). The selectable range of a welding

parameter corresponds to the range which is selectable at the front panel. The settings can be monitored at

the displays of the welding machine.

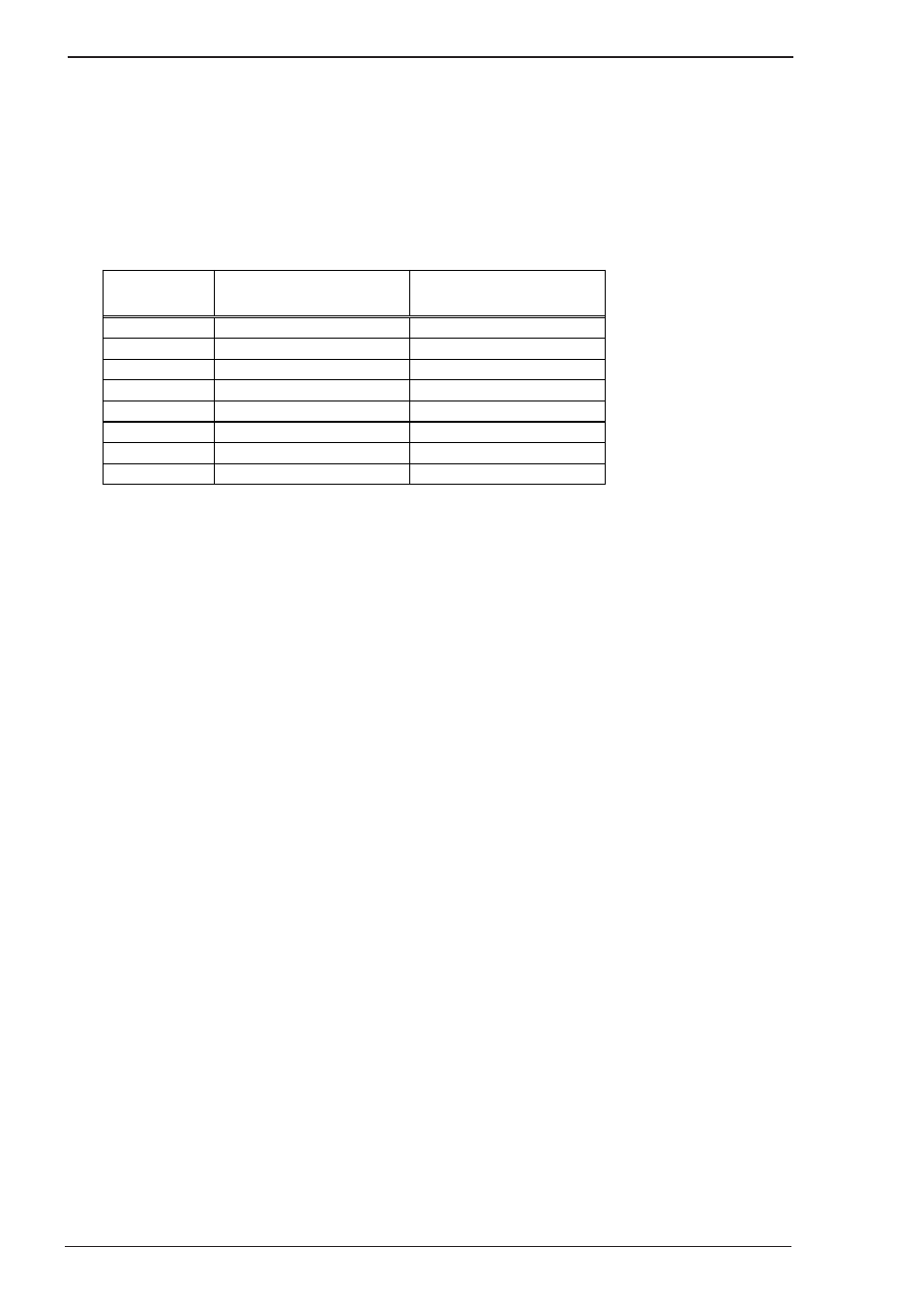

The factory default-assignment is:

Input

Harting socket

Pin no.

Standard Configuration

Parameter

A1 23 welding current

A2 24

arc length

A3 25 start current

A4 26

downslope

A5 27 start current time

A6 28

end current

A7 29 end current time

A8 30

twin pulse frequency

Programming the analog inputs:

Programming the analog inputs (assignment to welding parameters) is made with a PC with CAN

interface (see section 5.09 "Robot Tool Software Installation").